What is Global Medical Grade Polypropylene Market?

The Global Medical Grade Polypropylene Market is a specialized segment of the broader polypropylene market, focusing on materials used in healthcare applications. Polypropylene, a versatile thermoplastic polymer, is favored in the medical field for its excellent chemical resistance, durability, and cost-effectiveness. Medical grade polypropylene is specifically formulated to meet stringent regulatory standards and is used in various healthcare applications, including medical devices, packaging, and other healthcare products. This market is driven by the increasing demand for safe, reliable, and cost-effective materials in the healthcare industry. The growing global population, aging demographics, and advancements in medical technology further fuel the demand for medical grade polypropylene. Additionally, the need for disposable medical products, which require materials that can withstand sterilization processes, contributes to the market's growth. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for high-quality, affordable materials like medical grade polypropylene is expected to continue rising. This market is characterized by continuous innovation, with manufacturers developing new formulations and applications to meet the evolving needs of the healthcare sector.

PP-H, PP-B, PP-R in the Global Medical Grade Polypropylene Market:

Polypropylene is a versatile polymer that comes in various grades, each with unique properties and applications. In the Global Medical Grade Polypropylene Market, three primary types are PP-H (Polypropylene Homopolymer), PP-B (Polypropylene Block Copolymer), and PP-R (Polypropylene Random Copolymer). PP-H is known for its high strength and rigidity, making it suitable for applications requiring durability and resistance to high temperatures. It is often used in medical devices that need to withstand repeated sterilization processes. PP-B, on the other hand, is a block copolymer that offers improved impact resistance and toughness compared to PP-H. This makes it ideal for applications where flexibility and resilience are crucial, such as in medical packaging that must endure handling and transportation stresses. PP-R is a random copolymer that combines the properties of both PP-H and PP-B, offering a balance of strength, flexibility, and clarity. It is often used in applications where transparency and aesthetic appeal are important, such as in medical containers and packaging. Each of these polypropylene types is engineered to meet specific regulatory standards for medical applications, ensuring safety and performance in healthcare settings. The choice of polypropylene type depends on the specific requirements of the application, including mechanical properties, chemical resistance, and sterilization compatibility. Manufacturers in the Global Medical Grade Polypropylene Market continuously innovate to develop new formulations and applications, addressing the evolving needs of the healthcare industry. This includes enhancing the material's biocompatibility, reducing leachables and extractables, and improving processing efficiency. The market is also influenced by regulatory changes and advancements in medical technology, which drive the demand for new and improved materials. As the healthcare industry continues to grow and evolve, the demand for high-quality, reliable, and cost-effective materials like medical grade polypropylene is expected to increase. This market is characterized by intense competition, with manufacturers striving to develop innovative solutions that meet the stringent requirements of the healthcare sector. The Global Medical Grade Polypropylene Market is a dynamic and rapidly evolving segment, driven by the need for safe, effective, and affordable materials in healthcare applications.

Medical Device, Medical Packaging, Other in the Global Medical Grade Polypropylene Market:

The Global Medical Grade Polypropylene Market plays a crucial role in various healthcare applications, including medical devices, medical packaging, and other healthcare products. In the medical device sector, polypropylene is used to manufacture a wide range of products, from syringes and IV components to surgical instruments and diagnostic equipment. Its excellent chemical resistance, durability, and ability to withstand sterilization processes make it an ideal material for medical devices that require high performance and reliability. Additionally, polypropylene's lightweight nature and cost-effectiveness contribute to its widespread use in the medical device industry. In medical packaging, polypropylene is used to produce containers, bottles, and films that protect medical products from contamination and damage. Its barrier properties, combined with its ability to be easily molded into various shapes and sizes, make it a popular choice for packaging applications. Polypropylene's resistance to moisture, chemicals, and temperature variations ensures the integrity and safety of medical products during storage and transportation. Furthermore, its transparency and clarity allow for easy inspection of packaged products, enhancing safety and quality control. Beyond medical devices and packaging, polypropylene is used in other healthcare applications, such as laboratory equipment, personal protective equipment, and healthcare textiles. Its versatility and adaptability make it suitable for a wide range of applications, addressing the diverse needs of the healthcare industry. The demand for medical grade polypropylene is driven by the increasing need for safe, reliable, and cost-effective materials in healthcare applications. As the global population continues to grow and age, the demand for healthcare services and products is expected to rise, further fueling the need for high-quality materials like medical grade polypropylene. The market is characterized by continuous innovation, with manufacturers developing new formulations and applications to meet the evolving needs of the healthcare sector. This includes enhancing the material's biocompatibility, reducing leachables and extractables, and improving processing efficiency. The Global Medical Grade Polypropylene Market is a dynamic and rapidly evolving segment, driven by the need for safe, effective, and affordable materials in healthcare applications.

Global Medical Grade Polypropylene Market Outlook:

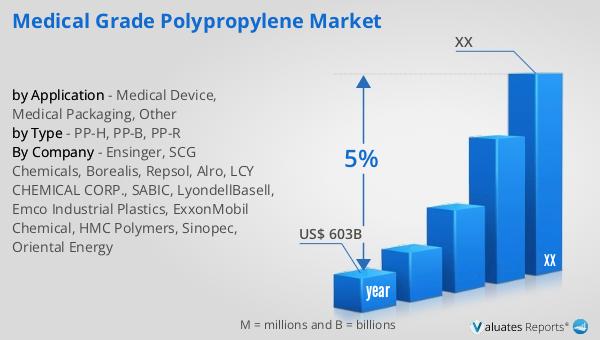

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including technological advancements, an aging global population, and increasing healthcare expenditures. As medical technology continues to evolve, there is a growing demand for innovative devices that improve patient outcomes and streamline healthcare delivery. The aging population, particularly in developed countries, is leading to an increased prevalence of chronic diseases, which in turn drives the demand for medical devices. Additionally, rising healthcare expenditures in emerging markets are contributing to the growth of the medical device market, as governments and private sectors invest in healthcare infrastructure and services. The Global Medical Grade Polypropylene Market is closely linked to the medical device market, as polypropylene is a key material used in the manufacturing of various medical devices. The demand for high-quality, reliable, and cost-effective materials like medical grade polypropylene is expected to increase in tandem with the growth of the medical device market. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for innovative materials and solutions will continue to rise. The Global Medical Grade Polypropylene Market is poised for growth, driven by the increasing demand for safe, effective, and affordable materials in healthcare applications.

| Report Metric | Details |

| Report Name | Medical Grade Polypropylene Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ensinger, SCG Chemicals, Borealis, Repsol, Alro, LCY CHEMICAL CORP., SABIC, LyondellBasell, Emco Industrial Plastics, ExxonMobil Chemical, HMC Polymers, Sinopec, Oriental Energy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |