What is Cationic Exchange Chromatography Resin - Global Market?

Cationic exchange chromatography resin is a specialized material used in the separation and purification processes within various industries. This resin operates on the principle of ion exchange, where positively charged ions (cations) in a solution are exchanged with cations attached to the resin. The global market for cationic exchange chromatography resin is driven by its extensive applications in fields such as pharmaceuticals, biotechnology, food and beverage testing, and environmental analysis. These resins are crucial in purifying proteins, peptides, and other biomolecules, ensuring high purity and quality in the final products. The demand for these resins is increasing due to the growing need for efficient and reliable separation techniques in research and industrial applications. As industries continue to expand and innovate, the role of cationic exchange chromatography resins becomes even more significant, supporting advancements in product development and quality assurance.

Strong Cation Exchange Resin, Weak Cation Exchange Resin in the Cationic Exchange Chromatography Resin - Global Market:

Strong cation exchange resins and weak cation exchange resins are two primary types of cationic exchange chromatography resins, each with distinct characteristics and applications. Strong cation exchange resins are characterized by their ability to operate over a wide pH range, typically from 0 to 14. They contain sulfonic acid groups, which are strong acidic functional groups that remain ionized across this pH spectrum. This makes them highly effective in binding and separating cations, even in highly acidic or basic environments. These resins are commonly used in applications where a robust and consistent ion exchange process is required, such as in the purification of proteins and peptides in pharmaceutical manufacturing. Their stability and efficiency make them a preferred choice for processes that demand high throughput and precision. On the other hand, weak cation exchange resins contain carboxylic acid groups, which are weak acidic functional groups. These resins operate effectively within a narrower pH range, typically between 4 and 10. The ionization of the carboxylic groups is pH-dependent, which allows for more selective binding and elution of cations based on the pH of the solution. This selectivity is advantageous in applications where specific separation of closely related molecules is required, such as in the analysis and purification of complex biological samples. Weak cation exchange resins are often used in research and development settings where fine-tuning of separation conditions is necessary to achieve desired results. The choice between strong and weak cation exchange resins depends on the specific requirements of the application, including the nature of the sample, the desired separation resolution, and the operational conditions. Both types of resins play a crucial role in the global market for cationic exchange chromatography, catering to diverse needs across various industries. As the demand for high-quality separation and purification processes continues to grow, the development and optimization of these resins remain a focal point for manufacturers and researchers alike.

Pharmaceutical, Life Sciences, Food and Beverage Testing, Environmental Testing, Others in the Cationic Exchange Chromatography Resin - Global Market:

Cationic exchange chromatography resins find extensive usage across several key areas, including pharmaceuticals, life sciences, food and beverage testing, environmental testing, and other industries. In the pharmaceutical sector, these resins are indispensable for the purification of drugs and biologics. They help in removing impurities and ensuring the high purity of active pharmaceutical ingredients (APIs), which is critical for drug safety and efficacy. The ability of these resins to selectively bind and separate charged molecules makes them ideal for purifying complex biological products, such as monoclonal antibodies and vaccines. In the life sciences field, cationic exchange chromatography resins are used in research and development to study proteins, nucleic acids, and other biomolecules. They facilitate the separation and analysis of these molecules, aiding in the understanding of biological processes and the development of new therapies. In food and beverage testing, these resins are employed to ensure product safety and quality. They help in detecting and quantifying contaminants, such as heavy metals and other cations, ensuring compliance with regulatory standards. Environmental testing also benefits from the use of cationic exchange chromatography resins, as they are used to monitor and analyze pollutants in water and soil. This application is crucial for environmental protection and public health, as it helps in identifying and mitigating sources of contamination. Other industries, such as chemical manufacturing and biotechnology, also utilize these resins for various separation and purification processes. The versatility and efficiency of cationic exchange chromatography resins make them a valuable tool in ensuring product quality and safety across multiple sectors.

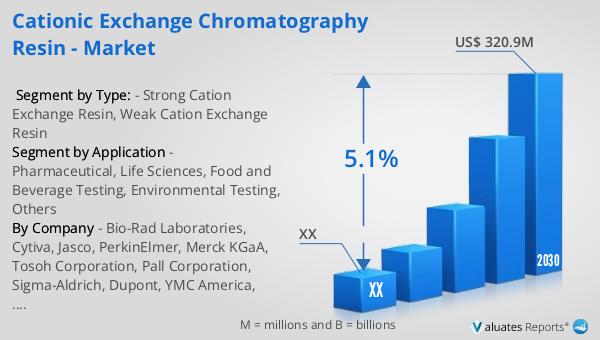

Cationic Exchange Chromatography Resin - Global Market Outlook:

The global market for cationic exchange chromatography resin was valued at approximately $225.4 million in 2023. It is projected to grow to a revised size of $320.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.1% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand for chemical applications that require precise and efficient separation processes. The chemical industry plays a significant role in this market, as it relies heavily on cationic exchange chromatography resins for the purification and separation of various compounds. The ability of these resins to selectively bind and separate cations makes them indispensable in chemical manufacturing, where purity and quality are paramount. As industries continue to innovate and expand, the demand for high-performance chromatography resins is expected to rise, further driving market growth. The versatility and efficiency of cationic exchange chromatography resins make them a valuable tool in ensuring product quality and safety across multiple sectors. This market outlook highlights the importance of these resins in supporting advancements in product development and quality assurance, as well as their role in meeting the growing demand for efficient separation techniques in research and industrial applications.

| Report Metric | Details |

| Report Name | Cationic Exchange Chromatography Resin - Market |

| Forecasted market size in 2030 | US$ 320.9 million |

| CAGR | 5.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bio-Rad Laboratories, Cytiva, Jasco, PerkinElmer, Merck KGaA, Tosoh Corporation, Pall Corporation, Sigma-Aldrich, Dupont, YMC America, Agilent Technologies, Thermo Fisher Scientific, Siemens AG, GE Healthcare Life Sciences, Tokyo Chemicals Industries Co. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |