What is Global Cart Lifters Market?

The Global Cart Lifters Market is a specialized segment within the broader material handling equipment industry. Cart lifters are mechanical devices designed to lift and transport carts or bins, making them essential tools in various industries for improving efficiency and reducing manual labor. These devices are particularly useful in environments where heavy lifting is frequent, such as warehouses, manufacturing plants, and waste management facilities. The market for cart lifters is driven by the increasing need for automation and ergonomic solutions in workplaces to enhance productivity and ensure worker safety. As industries continue to prioritize operational efficiency and employee well-being, the demand for cart lifters is expected to grow. These lifters come in various types and configurations, catering to different operational needs and environments. They are often integrated with other systems, such as conveyor belts or automated guided vehicles, to streamline processes further. The global market is characterized by a mix of established manufacturers and emerging players, all striving to innovate and offer more efficient, durable, and cost-effective solutions. As businesses continue to evolve and adapt to new challenges, the role of cart lifters in facilitating seamless operations becomes increasingly significant.

Stationary Type, Mobile Type in the Global Cart Lifters Market:

In the Global Cart Lifters Market, two primary types of cart lifters are prevalent: stationary and mobile. Stationary cart lifters are fixed in one location and are typically used in environments where the lifting and dumping of carts occur at a specific point. These lifters are often integrated into production lines or waste management systems, where they perform repetitive tasks with high precision. The advantage of stationary lifters lies in their stability and ability to handle heavy loads consistently. They are designed to be robust and durable, capable of withstanding the rigors of continuous operation. Stationary lifters are commonly found in industrial settings, such as manufacturing plants and recycling facilities, where they contribute to streamlining operations and enhancing productivity. On the other hand, mobile cart lifters offer flexibility and versatility, as they can be moved to different locations as needed. These lifters are equipped with wheels or tracks, allowing them to navigate various terrains and reach different areas within a facility. Mobile lifters are ideal for environments where the lifting tasks are not confined to a single location, such as large warehouses or distribution centers. They provide the advantage of adaptability, enabling businesses to respond quickly to changing operational needs. Mobile lifters are also used in outdoor settings, such as construction sites or agricultural fields, where they assist in transporting materials or waste. The choice between stationary and mobile cart lifters depends on several factors, including the nature of the tasks, the layout of the facility, and the specific requirements of the operation. Both types of lifters are designed with safety features to protect operators and ensure smooth operation. These features may include automatic locking mechanisms, overload protection, and ergonomic controls. As technology advances, manufacturers are incorporating smart features into cart lifters, such as remote monitoring and control, to enhance their functionality and efficiency. The integration of IoT and automation technologies is expected to further drive innovation in the cart lifters market, offering new possibilities for optimizing material handling processes. In conclusion, stationary and mobile cart lifters each offer unique benefits and are essential tools in modern material handling operations. Their ability to improve efficiency, reduce manual labor, and enhance safety makes them valuable assets in various industries. As businesses continue to seek ways to optimize their operations, the demand for both stationary and mobile cart lifters is likely to remain strong.

Food Processing, Material Handling, Others in the Global Cart Lifters Market:

The Global Cart Lifters Market finds extensive application across various sectors, including food processing, material handling, and others. In the food processing industry, cart lifters play a crucial role in handling raw materials, ingredients, and finished products. They are used to lift and transport bins or carts filled with food items, ensuring efficient movement within the production facility. This not only speeds up the production process but also minimizes the risk of contamination by reducing manual handling. Cart lifters in food processing are often designed with hygiene in mind, featuring stainless steel construction and easy-to-clean surfaces. In material handling, cart lifters are indispensable tools for moving heavy loads within warehouses, distribution centers, and manufacturing plants. They help streamline operations by facilitating the quick and safe transfer of goods from one point to another. This is particularly important in environments where time is of the essence, and efficiency is paramount. Cart lifters reduce the need for manual lifting, thereby decreasing the risk of workplace injuries and improving overall productivity. In addition to food processing and material handling, cart lifters are used in various other industries, such as waste management, healthcare, and retail. In waste management, they assist in lifting and emptying bins, making the process more efficient and less labor-intensive. In healthcare settings, cart lifters are used to transport medical supplies and equipment, ensuring that essential items are readily available where needed. In retail, they help in the movement of goods from storage areas to the sales floor, facilitating inventory management and restocking. The versatility of cart lifters makes them valuable assets in any industry that requires the movement of heavy or bulky items. As businesses continue to seek ways to improve efficiency and safety, the demand for cart lifters in these areas is expected to grow.

Global Cart Lifters Market Outlook:

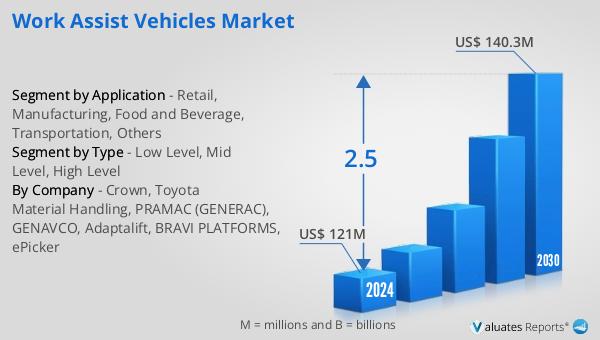

The outlook for the Global Cart Lifters Market indicates a steady growth trajectory, with projections suggesting an increase from US$ 92 million in 2024 to US$ 109.2 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 2.9% during the forecast period. The market's expansion is supported by the rising demand for efficient material handling solutions across various industries. According to research from our Construction Machinery center, the sales of construction machinery in Europe saw a significant increase of 24% in 2021. In 2022, the construction machinery revenue in Europe was approximately US$ 22 billion, while the US market recorded sales of about US$ 36 billion in construction machinery. Asian companies hold a dominant position in the market, accounting for 50% of the revenue, followed by Europe and North America, which account for 26% and 23%, respectively. This distribution highlights the global nature of the cart lifters market and the varying levels of demand across different regions. The growth in the cart lifters market is likely to be driven by the increasing emphasis on automation and ergonomic solutions in workplaces, as businesses strive to enhance productivity and ensure worker safety. As industries continue to evolve and adapt to new challenges, the role of cart lifters in facilitating seamless operations becomes increasingly significant.

| Report Metric | Details |

| Report Name | Cart Lifters Market |

| Accounted market size in 2024 | US$ 92 million |

| Forecasted market size in 2030 | US$ 109.2 million |

| CAGR | 2.9 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Wastequip, Environmental, QC Lifters, Ameri-Shred, MGF, MPBS Industrie, C&M BALING SYSTEM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |