What is Global Vacuum Dispersing Machine Market?

The Global Vacuum Dispersing Machine Market is a specialized segment within the broader industrial machinery market. These machines are designed to mix, disperse, and homogenize materials under vacuum conditions, which helps in eliminating air bubbles and improving the quality of the final product. The vacuum environment also enhances the efficiency of the dispersing process by reducing oxidation and contamination. These machines are widely used in various industries such as chemicals, pharmaceuticals, food and beverages, and cosmetics. The market for vacuum dispersing machines is driven by the increasing demand for high-quality, air-free products and the need for efficient mixing solutions in various industrial applications. Technological advancements and the growing emphasis on automation in manufacturing processes are also contributing to the market's growth. The market is characterized by the presence of several key players who offer a range of products catering to different industrial needs.

Single Shafts Dispersing Machine, Double Shafts Dispersing Machine in the Global Vacuum Dispersing Machine Market:

Single Shafts Dispersing Machines and Double Shafts Dispersing Machines are two primary types of vacuum dispersing machines used in the Global Vacuum Dispersing Machine Market. Single Shafts Dispersing Machines are designed with a single shaft that holds the dispersing tool. These machines are typically used for low to medium viscosity materials and are suitable for applications where the mixing process does not require high shear forces. They are commonly used in the production of paints, coatings, and adhesives. The single shaft design allows for easy maintenance and operation, making it a popular choice for small to medium-sized production facilities. On the other hand, Double Shafts Dispersing Machines are equipped with two shafts, each holding a dispersing tool. This design allows for more efficient mixing of high viscosity materials and provides better shear forces, making it ideal for applications that require thorough mixing and homogenization. Double Shafts Dispersing Machines are commonly used in the production of high-performance materials such as sealants, lubricants, and high-viscosity adhesives. The dual-shaft design also allows for better control over the mixing process, resulting in higher quality end products. Both types of machines are designed to operate under vacuum conditions, which helps in eliminating air bubbles and improving the quality of the final product. The choice between single and double shafts dispersing machines depends on the specific requirements of the application, including the viscosity of the materials being mixed, the desired shear forces, and the production volume.

Chemical Industry, Pharmaceutical Industry, Food and Beverage Industry, Cosmetics Industry, Other in the Global Vacuum Dispersing Machine Market:

The Global Vacuum Dispersing Machine Market finds extensive usage across various industries, including the Chemical Industry, Pharmaceutical Industry, Food and Beverage Industry, Cosmetics Industry, and others. In the Chemical Industry, vacuum dispersing machines are used for mixing and homogenizing chemicals to produce high-quality products such as paints, coatings, adhesives, and sealants. The vacuum environment helps in eliminating air bubbles and reducing oxidation, resulting in better product quality and stability. In the Pharmaceutical Industry, these machines are used for mixing and dispersing active pharmaceutical ingredients (APIs) and excipients to produce homogeneous mixtures for tablet and capsule formulations. The vacuum environment ensures that the mixing process is free from contamination and oxidation, which is crucial for maintaining the efficacy and stability of pharmaceutical products. In the Food and Beverage Industry, vacuum dispersing machines are used for mixing and homogenizing ingredients to produce high-quality food products such as sauces, dressings, and beverages. The vacuum environment helps in eliminating air bubbles and improving the texture and stability of the final product. In the Cosmetics Industry, these machines are used for mixing and dispersing ingredients to produce high-quality cosmetic products such as creams, lotions, and gels. The vacuum environment helps in eliminating air bubbles and improving the texture and stability of the final product. Other industries that use vacuum dispersing machines include the electronics industry for mixing and dispersing materials used in the production of electronic components, and the automotive industry for mixing and dispersing materials used in the production of automotive coatings and adhesives. The versatility and efficiency of vacuum dispersing machines make them an essential tool in various industrial applications.

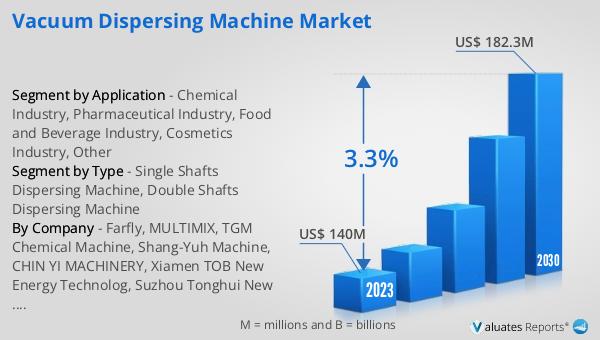

Global Vacuum Dispersing Machine Market Outlook:

The global Vacuum Dispersing Machine market was valued at US$ 140 million in 2023 and is anticipated to reach US$ 182.3 million by 2030, witnessing a CAGR of 3.3% during the forecast period 2024-2030. This market growth can be attributed to the increasing demand for high-quality, air-free products across various industries such as chemicals, pharmaceuticals, food and beverages, and cosmetics. The vacuum environment provided by these machines helps in eliminating air bubbles and reducing oxidation, resulting in better product quality and stability. Additionally, the growing emphasis on automation in manufacturing processes and technological advancements in vacuum dispersing machines are contributing to the market's growth. The market is characterized by the presence of several key players who offer a range of products catering to different industrial needs. These players are focusing on developing innovative and efficient vacuum dispersing machines to meet the evolving demands of various industries. The increasing adoption of vacuum dispersing machines in emerging economies is also expected to drive market growth during the forecast period.

| Report Metric | Details |

| Report Name | Vacuum Dispersing Machine Market |

| Accounted market size in 2023 | US$ 140 million |

| Forecasted market size in 2030 | US$ 182.3 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Farfly, MULTIMIX, TGM Chemical Machine, Shang-Yuh Machine, CHIN YI MACHINERY, Xiamen TOB New Energy Technolog, Suzhou Tonghui New Materials Equipment, KRS Dispermahltechnik, Jiangyin Shuangfeng Machinery, IDA, FRANLI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |