What is Global Glass Medical Tubing Market?

The Global Glass Medical Tubing Market is a specialized segment within the broader medical and pharmaceutical industries, focusing on the production and distribution of glass tubes used for various medical applications. These tubes are essential components in the manufacturing of medical devices, laboratory equipment, and pharmaceutical packaging. They are designed to meet stringent quality standards to ensure safety, durability, and compatibility with medical substances. The market encompasses a wide range of products, including single-hole glass tubes, multi-hole glass tubes, and porous glass tubes, each serving specific functions. The demand for glass medical tubing is driven by the increasing need for advanced medical treatments, the growth of the pharmaceutical industry, and the rising focus on research and development in healthcare. Additionally, the market is influenced by regulatory requirements and technological advancements that aim to improve the performance and reliability of medical devices. Overall, the Global Glass Medical Tubing Market plays a crucial role in supporting the healthcare infrastructure by providing high-quality materials that are vital for various medical and pharmaceutical applications.

Single-hole Glass Tube, Porous Glass Tube in the Global Glass Medical Tubing Market:

Single-hole glass tubes and porous glass tubes are two significant types of products within the Global Glass Medical Tubing Market, each serving distinct purposes. Single-hole glass tubes are primarily used in applications where a single, continuous channel is required. These tubes are often employed in the production of syringes, vials, and ampoules, which are essential for storing and administering medications. The single-hole design ensures a smooth and unobstructed flow of liquids, making them ideal for precise dosing and delivery of drugs. These tubes are made from high-quality borosilicate glass, which offers excellent chemical resistance and thermal stability, ensuring the integrity of the stored substances. On the other hand, porous glass tubes are designed with a network of interconnected pores, allowing for the controlled passage of gases or liquids. These tubes are commonly used in filtration, diffusion, and separation processes in medical and laboratory settings. The porous structure of these tubes enables them to trap and remove impurities, making them valuable in applications such as gas chromatography, dialysis, and water purification. Additionally, porous glass tubes are used in the development of advanced drug delivery systems, where they can facilitate the controlled release of therapeutic agents. Both single-hole and porous glass tubes are manufactured using advanced techniques to ensure high precision and consistency in their dimensions and properties. The production process involves melting and shaping high-purity glass materials, followed by rigorous quality control measures to meet industry standards. The versatility and reliability of these glass tubes make them indispensable in various medical and pharmaceutical applications, contributing to the overall growth and development of the Global Glass Medical Tubing Market.

Medical, Pharmaceutical, Research in the Global Glass Medical Tubing Market:

The Global Glass Medical Tubing Market finds extensive usage in the medical, pharmaceutical, and research sectors, each benefiting from the unique properties of glass tubing. In the medical field, glass tubes are crucial for the production of various medical devices and diagnostic tools. They are used in the manufacturing of syringes, blood collection tubes, and capillary tubes, which are essential for patient care and diagnostic procedures. The high chemical resistance and biocompatibility of glass ensure that these devices do not react with the biological samples or medications they come into contact with, maintaining their purity and effectiveness. In the pharmaceutical industry, glass medical tubing is vital for the packaging and storage of drugs. Glass vials, ampoules, and cartridges made from high-quality glass tubing provide a safe and inert environment for storing sensitive medications, including vaccines, biologics, and injectable drugs. The impermeability of glass to gases and moisture helps preserve the stability and shelf life of these pharmaceutical products. Furthermore, glass tubing is used in the production of inhalers and nebulizers, which are essential for delivering respiratory medications. In the research sector, glass medical tubing is indispensable for various laboratory applications. It is used in the construction of laboratory glassware, such as test tubes, pipettes, and chromatography columns, which are fundamental tools for conducting experiments and analyses. The transparency of glass allows researchers to observe reactions and processes in real-time, facilitating accurate data collection and analysis. Additionally, the thermal stability of glass makes it suitable for use in high-temperature applications, such as autoclaving and sterilization. Overall, the versatility and reliability of glass medical tubing make it a critical component in the medical, pharmaceutical, and research sectors, supporting advancements in healthcare and scientific research.

Global Glass Medical Tubing Market Outlook:

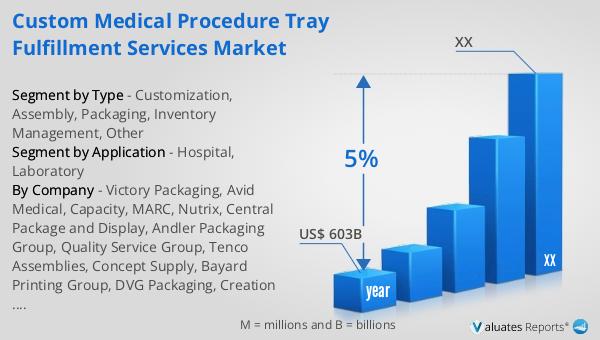

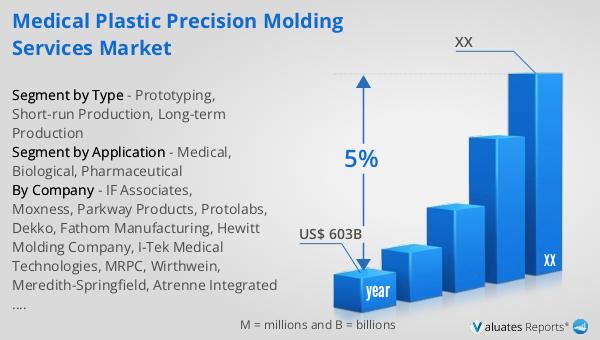

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion in 2023, with an anticipated growth rate of 5% CAGR over the next six years. This growth is driven by several factors, including the increasing demand for advanced medical treatments, the expansion of the pharmaceutical industry, and the rising focus on research and development in healthcare. The Global Glass Medical Tubing Market is expected to benefit from this overall growth in the medical devices sector, as glass tubing is a crucial component in the manufacturing of various medical and pharmaceutical products. The market's expansion is also supported by technological advancements and regulatory requirements that aim to improve the performance and reliability of medical devices. As the healthcare industry continues to evolve, the demand for high-quality glass medical tubing is likely to increase, contributing to the overall growth and development of the market. The projected growth rate reflects the ongoing efforts to enhance healthcare infrastructure and provide better medical solutions to patients worldwide.

| Report Metric | Details |

| Report Name | Glass Medical Tubing Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | SCHOTT, Technical Glass Products, Specialty Glass Products, VitroCom, King Precision Glass, NDS Technologies, Corning, Kavalier, Duran, De Dietrich |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |