What is Global Ultraviolet (UV) Curable Inks Market?

The Global Ultraviolet (UV) Curable Inks Market is a rapidly evolving sector within the printing and coatings industry. These inks are unique because they cure, or dry, almost instantly when exposed to ultraviolet light. This quick curing process offers several advantages over traditional inks, such as faster production speeds, reduced energy consumption, and lower emissions of volatile organic compounds (VOCs). As a result, UV curable inks are considered more environmentally friendly and efficient. They are used in various applications, including packaging, labels, and graphic arts, due to their ability to adhere to a wide range of substrates, including paper, plastic, and metal. The market is driven by increasing demand for sustainable printing solutions and advancements in UV technology, which have expanded the range of applications for these inks. Additionally, the growing popularity of digital printing and the need for high-quality, durable prints are further propelling the market's growth. As industries continue to seek eco-friendly and efficient printing solutions, the Global UV Curable Inks Market is poised for significant expansion in the coming years.

Offset Printing UV Curable Inks, Silkscreen Printing UV Curable Inks, Flexo Printing UV Curable Inks, Gravure UV Curable Inks, Digital Printing UV Curable Inks, Others in the Global Ultraviolet (UV) Curable Inks Market:

Offset Printing UV Curable Inks are specifically designed for use in offset printing processes, which are widely used for producing high-volume print materials such as newspapers, magazines, and brochures. These inks offer excellent adhesion and durability, making them ideal for printing on a variety of substrates, including paper and cardboard. The quick curing time of UV inks allows for faster production speeds and reduced downtime, which is particularly beneficial in high-volume printing environments. Silkscreen Printing UV Curable Inks are used in screen printing processes, where ink is pushed through a mesh screen onto the substrate. These inks are known for their vibrant colors and ability to print on a wide range of materials, including textiles, ceramics, and glass. The UV curing process ensures that the inks dry quickly and adhere well to the substrate, resulting in high-quality, durable prints. Flexo Printing UV Curable Inks are used in flexographic printing, a process commonly used for packaging materials such as labels, cartons, and flexible packaging. These inks are formulated to provide excellent adhesion and flexibility, allowing them to withstand the rigors of the packaging process. The quick curing time of UV inks also helps to reduce production times and improve efficiency. Gravure UV Curable Inks are used in gravure printing, a process that involves engraving the image onto a cylinder and transferring the ink onto the substrate. These inks are known for their high-quality prints and ability to produce fine details and vibrant colors. The UV curing process ensures that the inks dry quickly and adhere well to the substrate, resulting in durable, long-lasting prints. Digital Printing UV Curable Inks are used in digital printing processes, where the image is created digitally and printed directly onto the substrate. These inks offer excellent adhesion and durability, making them ideal for a wide range of applications, including signage, banners, and promotional materials. The quick curing time of UV inks allows for faster production speeds and reduced downtime, which is particularly beneficial in digital printing environments. Other types of UV curable inks include those used in specialty applications, such as 3D printing and electronics. These inks are formulated to meet the specific requirements of each application, providing excellent adhesion, durability, and flexibility. The versatility and efficiency of UV curable inks make them an attractive option for a wide range of printing applications, driving their growth in the global market.

Automobile, Consumer Goods, Medical, Publications and Printing, Others in the Global Ultraviolet (UV) Curable Inks Market:

The Global Ultraviolet (UV) Curable Inks Market finds extensive usage across various industries, including the automobile, consumer goods, medical, publications and printing, and others. In the automobile industry, UV curable inks are used for printing on various components, such as dashboards, instrument panels, and interior trims. The quick curing time and excellent adhesion of these inks make them ideal for use in automotive applications, where durability and resistance to environmental factors are crucial. In the consumer goods industry, UV curable inks are used for printing on packaging materials, labels, and promotional materials. The vibrant colors and high-quality prints produced by these inks make them an attractive option for consumer goods manufacturers looking to enhance the visual appeal of their products. In the medical industry, UV curable inks are used for printing on medical devices, packaging, and labels. The quick curing time and excellent adhesion of these inks make them ideal for use in medical applications, where precision and durability are essential. In the publications and printing industry, UV curable inks are used for printing on a wide range of materials, including paper, cardboard, and plastic. The quick curing time and excellent adhesion of these inks make them ideal for use in high-volume printing environments, where efficiency and quality are paramount. Other industries that use UV curable inks include electronics, textiles, and ceramics. The versatility and efficiency of these inks make them an attractive option for a wide range of applications, driving their growth in the global market.

Global Ultraviolet (UV) Curable Inks Market Outlook:

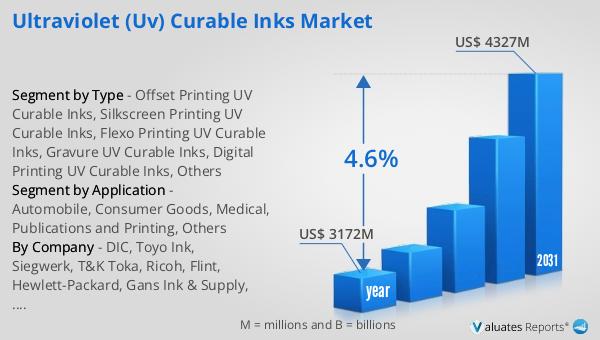

The worldwide market for Ultraviolet (UV) Curable Inks was valued at approximately $3,172 million in 2024. It is anticipated to expand to a revised size of around $4,327 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period. This growth is driven by the increasing demand for eco-friendly and efficient printing solutions across various industries. The quick curing time and excellent adhesion properties of UV curable inks make them an attractive option for a wide range of applications, from packaging and labels to automotive components and medical devices. As industries continue to seek sustainable and high-quality printing solutions, the demand for UV curable inks is expected to rise, contributing to the market's growth. The advancements in UV technology and the growing popularity of digital printing are also expected to play a significant role in driving the market's expansion. With the increasing focus on sustainability and efficiency, the Global UV Curable Inks Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Ultraviolet (UV) Curable Inks Market |

| Accounted market size in year | US$ 3172 million |

| Forecasted market size in 2031 | US$ 4327 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | DIC, Toyo Ink, Siegwerk, T&K Toka, Ricoh, Flint, Hewlett-Packard, Gans Ink & Supply, NUtec Digital Ink, Hanghua Toka, Letong Ink, Yip's Ink, Kingswood Inks, Tianjin Angel Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |