What is Global Medical Instrument Case Market?

The Global Medical Instrument Case Market refers to the worldwide industry focused on the production, distribution, and utilization of cases designed to store and transport medical instruments. These cases are essential for ensuring the safety, sterility, and organization of medical tools, which are crucial for various medical procedures. The market encompasses a wide range of products, including cases made from different materials such as metal, plastic, and composite materials. These cases are used in various healthcare settings, including hospitals, clinics, and ambulatory surgical centers, to protect delicate instruments from damage and contamination. The demand for medical instrument cases is driven by the increasing number of surgical procedures, the rising prevalence of chronic diseases, and the growing emphasis on infection control and patient safety. Additionally, advancements in medical technology and the development of new medical instruments further fuel the need for specialized cases. The market is characterized by a diverse range of manufacturers and suppliers, offering products with varying features, sizes, and price points to cater to the specific needs of healthcare providers. Overall, the Global Medical Instrument Case Market plays a vital role in the healthcare industry by ensuring the proper handling and storage of medical instruments, thereby contributing to improved patient outcomes and operational efficiency.

Metal Case, Plastic Case in the Global Medical Instrument Case Market:

In the Global Medical Instrument Case Market, metal cases and plastic cases are two of the most commonly used types of cases, each offering distinct advantages and disadvantages. Metal cases, typically made from materials such as aluminum or stainless steel, are known for their durability and strength. They provide excellent protection for medical instruments against physical damage, such as impacts and crushing forces. Metal cases are also resistant to high temperatures and can be easily sterilized, making them suitable for use in environments where stringent hygiene standards are required. However, metal cases can be relatively heavy and may be more expensive compared to other types of cases. On the other hand, plastic cases, often made from materials like polypropylene or ABS (Acrylonitrile Butadiene Styrene), are lightweight and cost-effective. They offer good protection against moisture and chemical exposure, which is important for maintaining the sterility of medical instruments. Plastic cases are also available in a wide range of colors and designs, allowing for easy identification and organization of instruments. However, they may not provide the same level of protection against physical damage as metal cases and may be less durable over time. Despite these differences, both metal and plastic cases play a crucial role in the Global Medical Instrument Case Market by catering to the diverse needs of healthcare providers. The choice between metal and plastic cases often depends on factors such as the specific requirements of the medical instruments being stored, the intended use environment, and budget considerations. In some cases, healthcare providers may opt for a combination of both types of cases to achieve a balance between durability, protection, and cost-effectiveness. Overall, the availability of both metal and plastic cases in the market ensures that healthcare providers have access to a variety of options to meet their specific needs, thereby enhancing the efficiency and effectiveness of medical instrument storage and transportation.

Hospital, Clinic in the Global Medical Instrument Case Market:

The usage of Global Medical Instrument Case Market in hospitals and clinics is integral to the daily operations and overall efficiency of these healthcare facilities. In hospitals, medical instrument cases are used extensively across various departments, including surgery, emergency, and intensive care units. These cases ensure that medical instruments are stored in an organized manner, making it easier for healthcare professionals to access the tools they need quickly and efficiently. In surgical settings, for example, the use of specialized instrument cases helps in maintaining the sterility of surgical tools, thereby reducing the risk of infections and improving patient outcomes. Additionally, the durability and protective features of these cases ensure that delicate and expensive instruments are safeguarded against damage during transportation and storage. In clinics, medical instrument cases are equally important, albeit on a smaller scale compared to hospitals. Clinics often deal with a high volume of patients and a wide range of medical procedures, necessitating the need for organized and easily accessible medical instruments. The use of instrument cases in clinics helps in streamlining operations, reducing the time spent searching for specific tools, and ensuring that instruments are kept in a sterile and ready-to-use condition. This is particularly important in clinics that perform minor surgical procedures, diagnostic tests, and other medical interventions. Furthermore, the portability of medical instrument cases is a significant advantage in both hospitals and clinics. Healthcare providers often need to move instruments between different departments or even off-site locations, such as during medical outreach programs or emergency response situations. Portable instrument cases facilitate the safe and efficient transportation of medical tools, ensuring that healthcare providers have the necessary equipment at their disposal, regardless of the location. Overall, the usage of medical instrument cases in hospitals and clinics is essential for maintaining the organization, sterility, and accessibility of medical instruments, thereby contributing to the overall quality of patient care and operational efficiency.

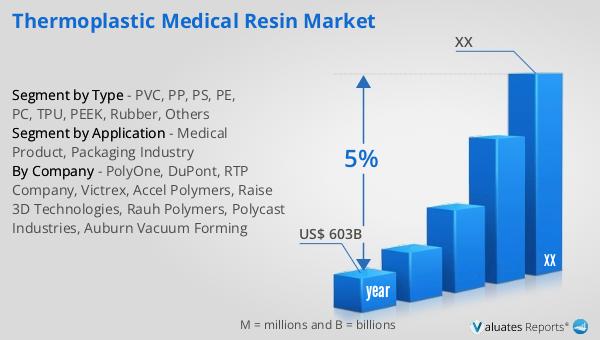

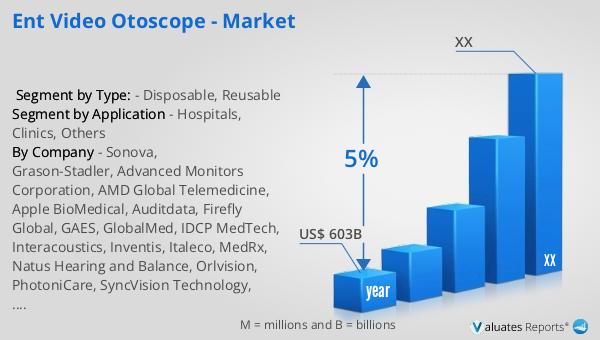

Global Medical Instrument Case Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This significant market size underscores the critical role that medical devices play in the healthcare industry, driving advancements in patient care and medical technology. The steady growth rate reflects the increasing demand for innovative medical solutions, driven by factors such as the aging population, the rising prevalence of chronic diseases, and the continuous development of new medical technologies. As the market expands, there will be a corresponding increase in the need for medical instrument cases to store and transport these devices safely and efficiently. The growth of the medical device market also highlights the importance of maintaining high standards of quality and safety in the production and distribution of medical instrument cases. Manufacturers and suppliers in the Global Medical Instrument Case Market must continue to innovate and adapt to meet the evolving needs of healthcare providers and patients. This includes developing new materials and designs that offer enhanced protection, durability, and ease of use. Additionally, the increasing focus on infection control and patient safety will drive the demand for cases that can maintain the sterility of medical instruments. Overall, the projected growth of the global medical device market presents significant opportunities and challenges for the Global Medical Instrument Case Market, emphasizing the need for continuous innovation and adherence to high standards of quality and safety.

| Report Metric | Details |

| Report Name | Medical Instrument Case Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | ZERO Manufacturing, Hudson Technologies, Estes Design & Manufacturing, CP Cases, Jewel Precision, Platt Cases, Bearse Manufacturing, Cases By Source, Case Design Corporation(CDC), Penn Products, Kurz Medical, Tecomet, Norseman Inc, Globe Tool and Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |