What is Global Solid Potassium Hydroxide Market?

The global Solid Potassium Hydroxide market is a significant segment within the broader chemical industry. Solid Potassium Hydroxide, also known as caustic potash, is a white, highly alkaline compound that is widely used in various industrial applications. It is produced through the electrolysis of potassium chloride solution, resulting in a solid form that can be easily handled and transported. The market for Solid Potassium Hydroxide is driven by its extensive use in the manufacturing of soaps, detergents, fertilizers, and various chemical processes. The demand for this compound is also influenced by its role in the production of biodiesel, where it acts as a catalyst. The market is characterized by a steady growth rate, driven by the increasing demand from end-use industries and the rising awareness about the benefits of using Solid Potassium Hydroxide in various applications. The market is also witnessing technological advancements that are aimed at improving the efficiency of production processes and reducing the environmental impact of manufacturing activities. Overall, the global Solid Potassium Hydroxide market is poised for continued growth, supported by its diverse range of applications and the ongoing developments in production technologies.

Pellets, Flakes, Powders in the Global Solid Potassium Hydroxide Market:

Solid Potassium Hydroxide is available in various forms, including pellets, flakes, and powders, each with its unique properties and applications. Pellets are small, cylindrical pieces of Solid Potassium Hydroxide that are easy to handle and measure. They are commonly used in applications where precise dosing is required, such as in laboratory settings and certain industrial processes. Pellets are also preferred in situations where dust generation needs to be minimized, as their compact form reduces the risk of airborne particles. Flakes, on the other hand, are thin, flat pieces of Solid Potassium Hydroxide that dissolve quickly in water, making them ideal for applications that require rapid solubility. Flakes are often used in the production of soaps and detergents, where their quick dissolution helps in the efficient mixing of ingredients. They are also used in the chemical industry for various synthesis processes. Powders are the most finely divided form of Solid Potassium Hydroxide and are used in applications that require a high surface area for rapid reaction rates. Powders are commonly used in the production of biodiesel, where they act as a catalyst to speed up the chemical reactions involved in the transesterification process. They are also used in the food industry for pH adjustment and as a stabilizing agent. Each form of Solid Potassium Hydroxide has its advantages and is chosen based on the specific requirements of the application. The versatility of Solid Potassium Hydroxide in its various forms makes it a valuable compound in numerous industrial processes, contributing to the overall growth of the market.

Chemical Industry, Oil Industry, Food Industry, Others in the Global Solid Potassium Hydroxide Market:

The usage of Solid Potassium Hydroxide spans across several industries, including the chemical industry, oil industry, food industry, and others. In the chemical industry, Solid Potassium Hydroxide is a crucial ingredient in the production of various chemicals, including potassium carbonate, potassium phosphates, and potassium soaps. It is also used in the manufacture of dyes, pharmaceuticals, and agricultural chemicals. The compound's strong alkaline properties make it an effective neutralizing agent in chemical reactions, and its ability to dissolve in water makes it suitable for use in aqueous solutions. In the oil industry, Solid Potassium Hydroxide is used in the refining of petroleum products. It is employed in the removal of acidic impurities from crude oil, which helps in improving the quality of the final product. The compound is also used in the production of biodiesel, where it acts as a catalyst in the transesterification process, converting vegetable oils and animal fats into biodiesel and glycerin. In the food industry, Solid Potassium Hydroxide is used as a food additive and processing aid. It is used in the production of cocoa, chocolate, and soft drinks, where it helps in pH adjustment and stabilization. The compound is also used in the peeling of fruits and vegetables, as well as in the processing of olives and other food products. Other industries that use Solid Potassium Hydroxide include the textile industry, where it is used in the mercerization of cotton, and the paper industry, where it is used in the pulping and bleaching processes. The compound is also used in the production of batteries, where it serves as an electrolyte in alkaline batteries. The diverse applications of Solid Potassium Hydroxide across various industries highlight its importance as a versatile and valuable chemical compound.

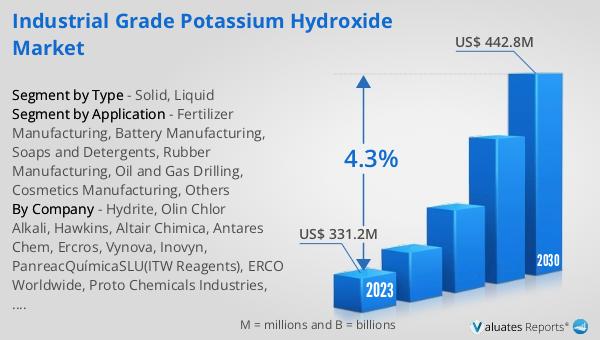

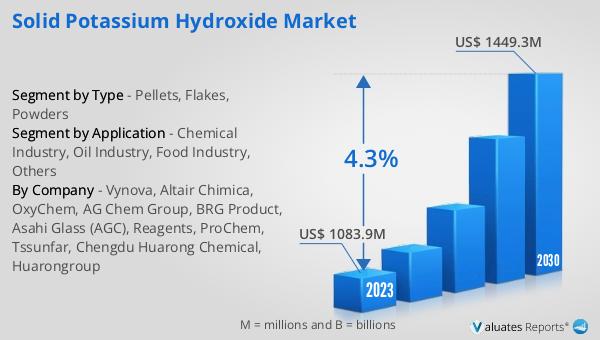

Global Solid Potassium Hydroxide Market Outlook:

The global Solid Potassium Hydroxide market was valued at approximately $1,083.9 million in 2023. Projections indicate that this market is expected to grow significantly, reaching around $1,449.3 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This upward trend can be attributed to the increasing demand for Solid Potassium Hydroxide across various industries, including chemicals, oil, food, and others. The compound's versatility and wide range of applications make it a critical component in many industrial processes. Additionally, advancements in production technologies and the development of more efficient manufacturing processes are expected to further drive the market's growth. The steady increase in demand from end-use industries, coupled with the ongoing technological innovations, underscores the positive outlook for the global Solid Potassium Hydroxide market. As industries continue to seek more efficient and sustainable solutions, the demand for Solid Potassium Hydroxide is likely to remain strong, supporting its market growth in the coming years.

| Report Metric | Details |

| Report Name | Solid Potassium Hydroxide Market |

| Accounted market size in 2023 | US$ 1083.9 million |

| Forecasted market size in 2030 | US$ 1449.3 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Vynova, Altair Chimica, OxyChem, AG Chem Group, BRG Product, Asahi Glass (AGC), Reagents, ProChem, Tssunfar, Chengdu Huarong Chemical, Huarongroup |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |