What is Global Evaporation Device Market?

The Global Evaporation Device Market refers to the worldwide industry focused on the production, distribution, and utilization of devices designed to facilitate the process of evaporation. Evaporation devices are essential in various industries for concentrating solutions, removing solvents, and purifying substances. These devices work by converting liquid into vapor, which is then collected or discarded, depending on the application. The market encompasses a wide range of products, including rotary evaporators, thin-film evaporators, and falling film evaporators, among others. These devices are used in laboratories, industrial processes, and even in household appliances. The demand for evaporation devices is driven by their critical role in sectors such as pharmaceuticals, food and beverage, chemicals, and environmental management. As industries continue to seek efficient and cost-effective methods for processing and purifying substances, the global evaporation device market is expected to grow, driven by technological advancements and increasing applications across various fields.

Fooded Evaporator, Dry Evaporator, Circulating Evaporator, Spray Evaporator in the Global Evaporation Device Market:

Flooded evaporators, dry evaporators, circulating evaporators, and spray evaporators are key types of evaporation devices used in the global market, each serving distinct purposes and applications. Flooded evaporators are designed to operate with a large amount of refrigerant, ensuring that the evaporator coil is always filled with liquid refrigerant. This type of evaporator is highly efficient and is commonly used in large-scale industrial applications where maintaining a consistent temperature is crucial. Dry evaporators, on the other hand, operate with a minimal amount of refrigerant, allowing for quicker temperature changes and more precise control. These are often used in applications where rapid cooling or heating is required, such as in certain laboratory settings or specialized industrial processes. Circulating evaporators involve the continuous circulation of the liquid being evaporated, which helps to maintain uniform temperature and concentration levels throughout the process. This type of evaporator is particularly useful in processes where the consistency of the final product is critical, such as in the production of pharmaceuticals or high-quality food products. Spray evaporators work by spraying the liquid to be evaporated into a heated chamber, where it quickly turns into vapor. This method is highly efficient and is often used in applications where rapid evaporation is needed, such as in the production of powdered products or in certain chemical processes. Each of these evaporator types plays a vital role in the global evaporation device market, catering to the diverse needs of various industries and applications.

Chemical Industry, Food Industry, Appliance Industry in the Global Evaporation Device Market:

The global evaporation device market finds extensive usage across several key industries, including the chemical industry, food industry, and appliance industry. In the chemical industry, evaporation devices are crucial for processes such as solvent recovery, concentration of chemical solutions, and purification of products. These devices help in reducing waste, improving product quality, and enhancing process efficiency. For instance, rotary evaporators are commonly used in chemical laboratories for the removal of solvents from samples, while large-scale industrial evaporators are employed in the production of chemicals like acids, bases, and salts. In the food industry, evaporation devices are used for concentrating juices, milk, and other liquid food products, as well as for drying and powdering processes. These devices help in preserving the nutritional value and flavor of food products while extending their shelf life. Spray evaporators, for example, are widely used in the production of powdered milk and instant coffee. In the appliance industry, evaporation devices are integral components of refrigeration and air conditioning systems. They help in the efficient transfer of heat, ensuring that appliances operate effectively and consume less energy. Flooded evaporators, in particular, are commonly used in large commercial refrigeration systems, while dry evaporators are often found in household refrigerators and air conditioners. The versatility and efficiency of evaporation devices make them indispensable across these industries, driving their demand and fostering innovation in the global market.

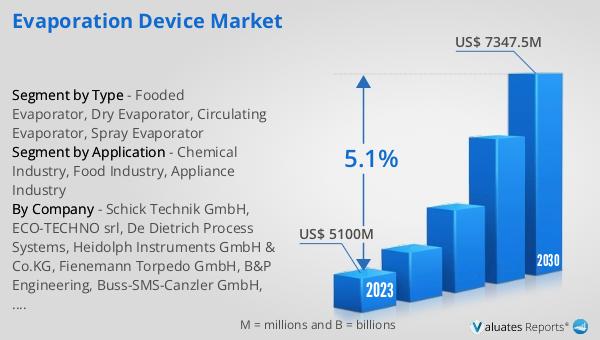

Global Evaporation Device Market Outlook:

The global evaporation device market was valued at US$ 5100 million in 2023 and is anticipated to reach US$ 7347.5 million by 2030, witnessing a CAGR of 5.1% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the evaporation device market over the coming years. The increasing demand for efficient and cost-effective evaporation solutions across various industries is a key driver of this growth. Technological advancements in evaporation devices, such as improved energy efficiency, enhanced automation, and better control systems, are also contributing to the market's expansion. Additionally, the growing focus on sustainability and environmental conservation is encouraging industries to adopt advanced evaporation technologies that minimize waste and reduce energy consumption. As a result, the global evaporation device market is poised for substantial growth, offering numerous opportunities for manufacturers, suppliers, and end-users alike. The projected increase in market value underscores the importance of evaporation devices in modern industrial processes and their critical role in achieving operational efficiency and product quality.

| Report Metric | Details |

| Report Name | Evaporation Device Market |

| Accounted market size in 2023 | US$ 5100 million |

| Forecasted market size in 2030 | US$ 7347.5 million |

| CAGR | 5.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schick Technik GmbH, ECO-TECHNO srl, De Dietrich Process Systems, Heidolph Instruments GmbH & Co.KG, Fienemann Torpedo GmbH, B&P Engineering, Buss-SMS-Canzler GmbH, AEL Apparatebau GmbH Leisnig, SCHWÄMMLE GmbH & Co. KG, KASAG Swiss AG, Hering AG, GEA Group Aktiengesellschaft |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |