What is Global Graphitic Cathode Block Market?

The Global Graphitic Cathode Block Market is a specialized segment within the broader industrial materials sector, focusing on the production and distribution of graphitic cathode blocks. These blocks are primarily used in the aluminum smelting industry, where they serve as a critical component in the electrolytic cells used for aluminum production. Graphitic cathode blocks are valued for their high thermal and electrical conductivity, resistance to chemical erosion, and ability to withstand extreme temperatures, making them indispensable in the efficient and sustainable production of aluminum. The market for these blocks is driven by the increasing demand for aluminum across various industries, including automotive, construction, and packaging. As industries continue to seek lightweight and durable materials, the demand for aluminum—and consequently, graphitic cathode blocks—continues to rise. Additionally, advancements in technology and manufacturing processes are enhancing the quality and performance of these blocks, further fueling market growth. The global market is characterized by a mix of established players and emerging companies, all striving to innovate and meet the evolving needs of the aluminum industry. As environmental concerns and sustainability become more prominent, the market is also witnessing a shift towards more eco-friendly production methods and materials.

Bottom Block, Side Block in the Global Graphitic Cathode Block Market:

In the Global Graphitic Cathode Block Market, bottom blocks and side blocks play crucial roles in the construction and efficiency of electrolytic cells used in aluminum smelting. Bottom blocks, as the name suggests, form the base of the electrolytic cell. They are designed to withstand the intense heat and chemical reactions that occur during the smelting process. These blocks are engineered to provide excellent thermal conductivity, which is essential for maintaining the optimal temperature within the cell. The durability of bottom blocks is critical, as they must endure the weight of the molten aluminum and the corrosive nature of the electrolytic bath. Manufacturers of bottom blocks focus on enhancing their resistance to thermal shock and chemical erosion, ensuring a longer lifespan and reducing the frequency of cell maintenance and replacement. On the other hand, side blocks are positioned along the walls of the electrolytic cell. Their primary function is to contain the molten aluminum and the electrolyte, preventing any leakage and ensuring the integrity of the cell. Like bottom blocks, side blocks must exhibit high thermal and chemical resistance. However, they also need to provide structural support to the cell, maintaining its shape and stability throughout the smelting process. The design and material composition of side blocks are crucial in minimizing energy loss and maximizing the efficiency of the cell. In recent years, there has been a growing emphasis on improving the performance of both bottom and side blocks. Innovations in material science have led to the development of blocks with enhanced properties, such as increased thermal conductivity and reduced electrical resistance. These advancements contribute to more efficient aluminum production, lower energy consumption, and reduced environmental impact. Additionally, manufacturers are exploring sustainable production methods and materials, aligning with the global push towards greener industrial practices. The market for bottom and side blocks is highly competitive, with numerous players striving to offer superior products that meet the stringent demands of the aluminum industry. Companies are investing in research and development to create blocks that not only perform better but also offer cost advantages to aluminum producers. As the demand for aluminum continues to grow, driven by its applications in various sectors, the importance of high-quality bottom and side blocks in the Global Graphitic Cathode Block Market cannot be overstated. These components are integral to the efficiency, sustainability, and profitability of aluminum smelting operations worldwide.

Below 15 kw, 15-25kw, Above 25 kw in the Global Graphitic Cathode Block Market:

The Global Graphitic Cathode Block Market finds its applications across various power capacities, including below 15 kW, 15-25 kW, and above 25 kW, each serving distinct industrial needs. In the segment below 15 kW, graphitic cathode blocks are primarily utilized in smaller-scale aluminum production facilities or specialized applications where lower power consumption is a priority. These blocks are designed to offer high efficiency and durability, ensuring that even at lower power levels, the aluminum smelting process remains effective and sustainable. The focus in this segment is on optimizing the thermal and electrical properties of the blocks to maximize output while minimizing energy usage. As industries increasingly prioritize energy efficiency and cost-effectiveness, the demand for high-performance cathode blocks in this category is expected to grow. In the 15-25 kW range, graphitic cathode blocks are employed in medium-sized aluminum smelting operations. This segment represents a balance between power consumption and production capacity, catering to industries that require moderate levels of aluminum output. The blocks used in this category are engineered to withstand higher thermal and chemical stresses, ensuring longevity and consistent performance. Manufacturers in this segment focus on enhancing the structural integrity and thermal management capabilities of the blocks, allowing for more efficient heat dissipation and reduced energy loss. The 15-25 kW range is particularly significant for industries that are transitioning towards more sustainable practices, as it offers a viable solution for reducing carbon footprints while maintaining production efficiency. For applications above 25 kW, graphitic cathode blocks are integral to large-scale aluminum smelting operations. These blocks are designed to handle the intense demands of high-capacity production, where efficiency and durability are paramount. In this segment, the focus is on maximizing the thermal and electrical conductivity of the blocks, ensuring that they can support the high power levels required for large-scale aluminum production. The blocks must also exhibit exceptional resistance to thermal shock and chemical erosion, as they are subjected to extreme conditions over extended periods. Innovations in material science and manufacturing processes are crucial in this segment, as they enable the development of blocks that can meet the rigorous demands of high-capacity smelting operations. As the global demand for aluminum continues to rise, driven by its applications in automotive, construction, and other industries, the need for high-quality graphitic cathode blocks across all power capacities is expected to increase. Manufacturers are investing in research and development to create blocks that not only meet the current demands but also anticipate future needs, ensuring that the Global Graphitic Cathode Block Market remains at the forefront of industrial innovation.

Global Graphitic Cathode Block Market Outlook:

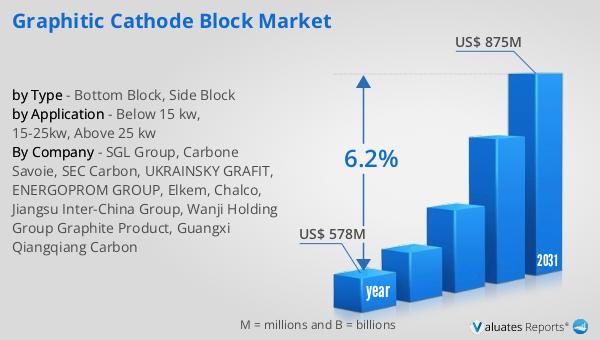

The global market for Graphitic Cathode Block was valued at $578 million in 2024 and is anticipated to expand to a revised size of $875 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth trajectory underscores the increasing demand for graphitic cathode blocks, driven by the expanding aluminum industry and the need for efficient and sustainable production methods. As industries worldwide continue to seek lightweight and durable materials, the demand for aluminum—and consequently, graphitic cathode blocks—continues to rise. The market's growth is further fueled by advancements in technology and manufacturing processes, which are enhancing the quality and performance of these blocks. Additionally, as environmental concerns and sustainability become more prominent, there is a shift towards more eco-friendly production methods and materials within the market. The competitive landscape of the Global Graphitic Cathode Block Market is characterized by a mix of established players and emerging companies, all striving to innovate and meet the evolving needs of the aluminum industry. As the market continues to grow, companies are investing in research and development to create blocks that not only perform better but also offer cost advantages to aluminum producers. This dynamic market environment presents numerous opportunities for growth and innovation, ensuring that the Global Graphitic Cathode Block Market remains a vital component of the industrial materials sector.

| Report Metric | Details |

| Report Name | Graphitic Cathode Block Market |

| Accounted market size in year | US$ 578 million |

| Forecasted market size in 2031 | US$ 875 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SGL Group, Carbone Savoie, SEC Carbon, UKRAINSKY GRAFIT, ENERGOPROM GROUP, Elkem, Chalco, Jiangsu Inter-China Group, Wanji Holding Group Graphite Product, Guangxi Qiangqiang Carbon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |