What is Global High Temperature Sealants Market?

The Global High Temperature Sealants Market is a specialized segment within the broader sealants industry, focusing on products that can withstand extreme temperatures. These sealants are crucial in various industries where high heat resistance is necessary, such as automotive, aerospace, and construction. High temperature sealants are designed to maintain their adhesive properties and structural integrity even when exposed to temperatures that would typically degrade standard sealants. They are used to prevent leaks, block the passage of fluids, and provide insulation in high-temperature environments. The market for these sealants is driven by the increasing demand for durable and reliable materials that can perform under extreme conditions. As industries continue to push the boundaries of technology and performance, the need for high temperature sealants is expected to grow. These sealants are typically made from materials like silicone, epoxy, and polyurethane, each offering unique properties that cater to specific applications. The global market for high temperature sealants is characterized by innovation and the development of new formulations that enhance performance and sustainability. Companies in this market are continually researching and developing new products to meet the evolving needs of their customers.

Silica Gel, Epoxy Resin, Other in the Global High Temperature Sealants Market:

Silica gel, epoxy resin, and other materials play a significant role in the Global High Temperature Sealants Market, each offering distinct advantages and applications. Silica gel is a highly porous form of silicon dioxide and is known for its excellent thermal stability and moisture absorption properties. In the context of high temperature sealants, silica gel is often used as a filler to enhance the thermal resistance and mechanical strength of the sealant. Its ability to withstand high temperatures without degrading makes it an ideal component in sealants used in demanding environments such as automotive engines and industrial machinery. Silica gel-based sealants are particularly valued for their ability to maintain performance in fluctuating temperatures, providing a reliable seal that prevents leaks and enhances safety. Epoxy resin, on the other hand, is a versatile material known for its strong adhesive properties and resistance to chemicals and heat. In high temperature sealants, epoxy resin is used to create a robust bond that can withstand extreme conditions. Its excellent adhesion to a variety of substrates, including metals, plastics, and ceramics, makes it a popular choice in industries such as aerospace and electronics, where reliable performance under high stress is critical. Epoxy-based sealants are often used in applications where a strong, durable bond is required, such as in the assembly of electronic components or the construction of aircraft parts. The ability of epoxy resin to cure at room temperature and its resistance to thermal cycling further enhance its suitability for high temperature applications. Other materials used in high temperature sealants include polyurethane, silicone, and polysulfide, each offering unique benefits. Polyurethane sealants are known for their flexibility and resistance to abrasion, making them suitable for applications where movement or vibration is expected. They are often used in the construction industry for sealing joints and gaps in buildings and infrastructure. Silicone sealants, renowned for their excellent thermal stability and weather resistance, are widely used in both industrial and consumer applications. They provide a flexible, waterproof seal that can withstand exposure to UV light and extreme temperatures, making them ideal for outdoor applications. Polysulfide sealants, with their exceptional chemical resistance and flexibility, are commonly used in the aerospace and marine industries, where exposure to harsh chemicals and environmental conditions is a concern. The choice of material in high temperature sealants depends on the specific requirements of the application, including the temperature range, substrate compatibility, and environmental conditions. Manufacturers in the Global High Temperature Sealants Market are continually innovating to develop new formulations that enhance the performance and sustainability of their products. This includes the development of eco-friendly sealants that reduce environmental impact while maintaining high performance standards. As industries continue to evolve and demand more from their materials, the role of silica gel, epoxy resin, and other materials in high temperature sealants will remain critical in meeting these challenges.

Electrical & Electronics, Transportation, Industrial, Construction, Other in the Global High Temperature Sealants Market:

The Global High Temperature Sealants Market finds extensive usage across various sectors, including electrical and electronics, transportation, industrial, construction, and others, each with specific requirements and challenges. In the electrical and electronics sector, high temperature sealants are essential for ensuring the reliability and safety of electronic components. These sealants are used to protect sensitive electronic parts from heat, moisture, and dust, which can compromise performance and lead to failures. They are commonly applied in the assembly of circuit boards, connectors, and other electronic devices where thermal management is crucial. The ability of high temperature sealants to provide a durable, insulating barrier makes them indispensable in this industry, where even minor failures can have significant consequences. In the transportation sector, high temperature sealants are used extensively in the automotive and aerospace industries. In automotive applications, these sealants are used to seal engine components, exhaust systems, and other parts exposed to high temperatures. They help prevent leaks, reduce noise and vibration, and enhance the overall performance and efficiency of vehicles. In the aerospace industry, high temperature sealants are used in the assembly and maintenance of aircraft, where they must withstand extreme temperatures and pressures. The reliability and durability of these sealants are critical in ensuring the safety and performance of aircraft, where failure is not an option. The industrial sector also relies heavily on high temperature sealants for a variety of applications. These sealants are used in the manufacturing and maintenance of machinery and equipment that operate under high temperatures. They help prevent leaks, protect against corrosion, and enhance the longevity of equipment, reducing downtime and maintenance costs. In industries such as oil and gas, chemical processing, and power generation, high temperature sealants are essential for maintaining the integrity and safety of equipment and infrastructure. In the construction industry, high temperature sealants are used to seal joints and gaps in buildings and infrastructure exposed to extreme temperatures. They provide a flexible, durable seal that can withstand thermal expansion and contraction, ensuring the structural integrity and energy efficiency of buildings. These sealants are used in applications such as sealing windows, doors, and roofing systems, where they help prevent air and water infiltration and enhance the comfort and safety of occupants. Other applications of high temperature sealants include their use in consumer products, such as ovens and grills, where they provide a safe, reliable seal that can withstand high temperatures. They are also used in the production of heat-resistant clothing and protective gear, where they help enhance the safety and performance of these products. The versatility and reliability of high temperature sealants make them an essential component in a wide range of applications, where they help enhance performance, safety, and efficiency. As industries continue to evolve and demand more from their materials, the role of high temperature sealants will remain critical in meeting these challenges.

Global High Temperature Sealants Market Outlook:

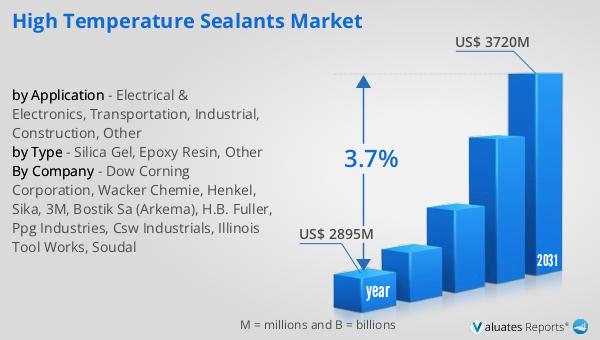

In 2024, the global market for High Temperature Sealants was valued at approximately US$ 2,895 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of US$ 3,720 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. The steady increase in market size reflects the rising demand for high-performance sealants capable of withstanding extreme temperatures across various industries. As technological advancements continue to push the boundaries of what is possible, the need for reliable and durable materials becomes increasingly critical. High temperature sealants are essential in applications where traditional sealants would fail, providing the necessary protection and performance in challenging environments. The projected growth of this market underscores the importance of innovation and development in creating sealants that meet the evolving needs of industries worldwide. Companies operating in this market are likely to focus on enhancing the performance and sustainability of their products, ensuring they remain competitive in a rapidly changing landscape. As the market continues to grow, it will offer new opportunities for businesses to expand their product offerings and reach new customers.

| Report Metric | Details |

| Report Name | High Temperature Sealants Market |

| Accounted market size in year | US$ 2895 million |

| Forecasted market size in 2031 | US$ 3720 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow Corning Corporation, Wacker Chemie, Henkel, Sika, 3M, Bostik Sa (Arkema), H.B. Fuller, Ppg Industries, Csw Industrials, Illinois Tool Works, Soudal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |