What is Global Fast Curing Nitrile Butadiene Rubber (NBR) Market?

The Global Fast Curing Nitrile Butadiene Rubber (NBR) Market is a specialized segment within the broader synthetic rubber industry, focusing on a type of rubber known for its rapid curing properties. Fast curing NBR is a synthetic copolymer derived from acrylonitrile and butadiene, which is particularly valued for its resistance to oils, fuels, and other chemicals. This makes it an essential material in various industrial applications where durability and resistance to harsh conditions are required. The market for fast curing NBR is driven by its widespread use in automotive, oil and gas, and industrial sectors, where it is used to manufacture products like hoses, seals, and gaskets. The demand for fast curing NBR is also influenced by its application in the production of gloves, adhesives, and sealants, which are critical in medical and construction industries. The market is characterized by continuous innovation and development to enhance the performance characteristics of NBR, making it more adaptable to evolving industrial needs. As industries continue to seek materials that offer both performance and cost-effectiveness, the global fast curing NBR market is poised for steady growth, driven by technological advancements and increasing demand across various sectors.

Hoses, Belts, Cables, Molded & Extruded Products, Seals & O-rings, Rubber Compounds, Adhesives & Sealants, Gloves, Foamed Products, Others in the Global Fast Curing Nitrile Butadiene Rubber (NBR) Market:

In the realm of Global Fast Curing Nitrile Butadiene Rubber (NBR) Market, a diverse array of products is manufactured, each serving distinct industrial purposes. Hoses, for instance, are crucial components in automotive and industrial applications, where they are used to transport fluids and gases under varying pressure conditions. The fast curing nature of NBR ensures that these hoses are not only durable but also resistant to oil and chemical degradation, making them ideal for use in harsh environments. Belts, another significant product, are used in machinery and automotive engines to transmit power. The resilience and flexibility of fast curing NBR make it an excellent material for belts, ensuring they can withstand high temperatures and mechanical stress. Cables made from NBR are used in electrical and mechanical applications, where they provide insulation and protection against environmental factors. Molded and extruded products, such as gaskets and seals, benefit from the fast curing properties of NBR, which allow for precise manufacturing and enhanced performance in sealing applications. Seals and O-rings, often used in hydraulic and pneumatic systems, rely on the chemical resistance and elasticity of NBR to maintain integrity under pressure. Rubber compounds, which are mixtures of NBR with other materials, are tailored to meet specific performance requirements, enhancing the versatility of NBR in various applications. Adhesives and sealants made from NBR are used in construction and manufacturing to bond materials and seal joints, offering excellent adhesion and resistance to environmental factors. Gloves, particularly those used in medical and industrial settings, benefit from the fast curing properties of NBR, which provide a comfortable fit and resistance to punctures and chemicals. Foamed products, such as cushioning materials, utilize the lightweight and resilient nature of NBR to provide comfort and protection in consumer and industrial applications. Other products, including various custom-molded items, leverage the unique properties of fast curing NBR to meet specific industrial needs. The versatility and adaptability of fast curing NBR make it a valuable material across a wide range of products, each benefiting from its unique combination of durability, chemical resistance, and rapid curing capabilities.

Automotive, Mechanical Engineering, Oil & Gas, Metallurgy & Mining, Construction, Medical, Others in the Global Fast Curing Nitrile Butadiene Rubber (NBR) Market:

The usage of Global Fast Curing Nitrile Butadiene Rubber (NBR) Market spans several critical industries, each leveraging the unique properties of NBR to enhance performance and reliability. In the automotive sector, fast curing NBR is used extensively in the production of hoses, seals, and gaskets, where its resistance to oils and fuels is paramount. The material's ability to withstand high temperatures and mechanical stress makes it ideal for use in engine components and fuel systems, where durability and reliability are crucial. In mechanical engineering, NBR is used to manufacture components that require high resistance to wear and tear, such as belts and seals. The fast curing properties of NBR allow for efficient production processes, reducing downtime and increasing productivity. The oil and gas industry relies on NBR for its chemical resistance and durability, using it in the production of seals, gaskets, and hoses that must withstand harsh environmental conditions and corrosive substances. In metallurgy and mining, NBR is used in equipment and machinery components that require high resistance to abrasion and chemical exposure. The construction industry benefits from NBR's adhesive and sealing properties, using it in the production of sealants and adhesives that provide strong bonds and resistance to environmental factors. In the medical field, NBR is used to produce gloves and other protective equipment, where its resistance to punctures and chemicals is essential for safety and hygiene. Other industries, such as consumer goods and electronics, also utilize NBR for its versatility and performance characteristics, incorporating it into products that require durability and resistance to environmental factors. The widespread use of fast curing NBR across these industries highlights its importance as a material that offers both performance and cost-effectiveness, driving demand and innovation in the market.

Global Fast Curing Nitrile Butadiene Rubber (NBR) Market Outlook:

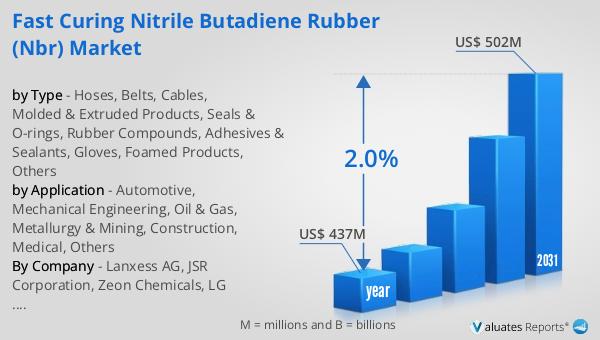

The outlook for the Global Fast Curing Nitrile Butadiene Rubber (NBR) Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 437 million, reflecting its significant role in various industrial applications. By 2031, it is anticipated that the market will expand to a revised size of US$ 502 million, growing at a compound annual growth rate (CAGR) of 2.0% during the forecast period. This growth is driven by the increasing demand for durable and chemically resistant materials across industries such as automotive, oil and gas, and construction. The fast curing properties of NBR make it an attractive choice for manufacturers seeking to enhance production efficiency and product performance. As industries continue to evolve and demand more specialized materials, the fast curing NBR market is expected to benefit from ongoing technological advancements and innovation. The market's growth is also supported by the rising need for materials that offer both performance and cost-effectiveness, making fast curing NBR a valuable component in a wide range of applications. The projected growth of the market underscores the importance of fast curing NBR as a key material in industrial manufacturing, with its unique properties driving demand and fostering innovation.

| Report Metric | Details |

| Report Name | Fast Curing Nitrile Butadiene Rubber (NBR) Market |

| Accounted market size in year | US$ 437 million |

| Forecasted market size in 2031 | US$ 502 million |

| CAGR | 2.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lanxess AG, JSR Corporation, Zeon Chemicals, LG Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |