What is Global Sterile Processing Isolators Market?

The Global Sterile Processing Isolators Market refers to the industry focused on the production and distribution of isolators used to maintain sterility in various processing environments. These isolators are essential in environments where maintaining a contamination-free space is critical, such as in pharmaceutical manufacturing, biotechnology, and healthcare settings. The market encompasses a range of products designed to protect both the product and the operator from contamination. These isolators are used to create a controlled environment that prevents the ingress of contaminants, ensuring that the processes carried out within them remain sterile. The demand for sterile processing isolators is driven by the increasing need for stringent contamination control in various industries, particularly in the production of pharmaceuticals and biologics. As regulatory requirements become more stringent and the focus on product quality intensifies, the market for sterile processing isolators is expected to grow. The market is characterized by technological advancements aimed at improving the efficiency and effectiveness of isolators, as well as by the development of new materials and designs that enhance their performance.

Sterility Production Isolator, Sterility Testing Isolator in the Global Sterile Processing Isolators Market:

Sterility Production Isolators and Sterility Testing Isolators are two critical components of the Global Sterile Processing Isolators Market. Sterility Production Isolators are designed to provide a controlled environment for the production of sterile products. These isolators are used in the manufacturing of pharmaceuticals, biologics, and other products that require a contamination-free environment. They are equipped with advanced filtration systems, airlocks, and other features that ensure the sterility of the production process. The use of Sterility Production Isolators is essential in industries where even the slightest contamination can compromise product quality and safety. On the other hand, Sterility Testing Isolators are used to test the sterility of products before they are released to the market. These isolators provide a controlled environment where products can be tested for the presence of contaminants. The testing process involves exposing the product to a sterile environment and monitoring it for any signs of contamination. Sterility Testing Isolators are equipped with advanced monitoring systems that detect even the smallest traces of contaminants, ensuring that only products that meet the highest standards of sterility are released to the market. Both types of isolators are essential in ensuring the safety and efficacy of products in industries where sterility is paramount. The demand for these isolators is driven by the increasing focus on product quality and safety, as well as by the growing regulatory requirements for sterility in various industries. As the market for sterile processing isolators continues to grow, manufacturers are investing in research and development to create more advanced and efficient isolators that meet the evolving needs of the industry. This includes the development of isolators with improved filtration systems, more efficient airlocks, and advanced monitoring systems that enhance their performance. The market is also characterized by the increasing adoption of automation and digital technologies, which are being integrated into isolators to improve their efficiency and effectiveness. These advancements are expected to drive the growth of the Global Sterile Processing Isolators Market in the coming years.

Hospitals and Diagnostics Labs, Pharmaceutical and Biotechnological, Others in the Global Sterile Processing Isolators Market:

The Global Sterile Processing Isolators Market finds significant application in various sectors, including hospitals and diagnostic labs, pharmaceutical and biotechnological industries, and other areas where maintaining sterility is crucial. In hospitals and diagnostic labs, sterile processing isolators are used to ensure that medical instruments and equipment are free from contaminants. This is essential in preventing infections and ensuring patient safety. The isolators provide a controlled environment where instruments can be sterilized and stored until they are needed for use. This is particularly important in surgical settings, where maintaining sterility is critical to preventing post-operative infections. In the pharmaceutical and biotechnological industries, sterile processing isolators are used in the production and testing of drugs and biologics. These isolators provide a contamination-free environment that ensures the safety and efficacy of the products being manufactured. They are used in various stages of the production process, from the initial formulation of the product to its final packaging. The use of sterile processing isolators in these industries is driven by the need to comply with stringent regulatory requirements for product safety and quality. In addition to hospitals, diagnostic labs, and pharmaceutical and biotechnological industries, sterile processing isolators are also used in other areas where maintaining sterility is essential. This includes research laboratories, where isolators are used to conduct experiments in a contamination-free environment. They are also used in the production of medical devices, where maintaining sterility is critical to ensuring the safety and efficacy of the devices. The demand for sterile processing isolators in these areas is driven by the increasing focus on product quality and safety, as well as by the growing regulatory requirements for sterility. As the market for sterile processing isolators continues to grow, manufacturers are investing in research and development to create more advanced and efficient isolators that meet the evolving needs of the industry. This includes the development of isolators with improved filtration systems, more efficient airlocks, and advanced monitoring systems that enhance their performance. The market is also characterized by the increasing adoption of automation and digital technologies, which are being integrated into isolators to improve their efficiency and effectiveness. These advancements are expected to drive the growth of the Global Sterile Processing Isolators Market in the coming years.

Global Sterile Processing Isolators Market Outlook:

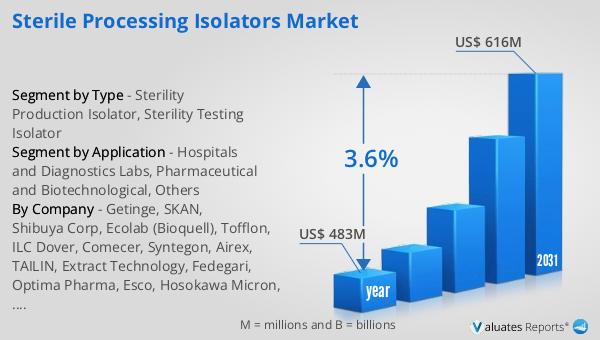

The global market for Sterile Processing Isolators was valued at $483 million in 2024 and is anticipated to expand to a revised size of $616 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth is indicative of the increasing demand for sterile processing solutions across various industries, driven by the need for stringent contamination control and compliance with regulatory standards. The market's expansion is supported by technological advancements and the development of more efficient and effective isolators that meet the evolving needs of the industry. In parallel, the global market for medical devices is estimated at $603 billion in 2023, with a projected CAGR of 5% over the next six years. This growth underscores the broader trend of increasing investment in healthcare and medical technologies, which is expected to drive demand for sterile processing isolators as part of the overall push for improved product safety and quality. As the market continues to evolve, manufacturers are focusing on innovation and the integration of digital technologies to enhance the performance and efficiency of sterile processing isolators, positioning them as critical components in the global healthcare and pharmaceutical landscape.

| Report Metric | Details |

| Report Name | Sterile Processing Isolators Market |

| Accounted market size in year | US$ 483 million |

| Forecasted market size in 2031 | US$ 616 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Getinge, SKAN, Shibuya Corp, Ecolab (Bioquell), Tofflon, ILC Dover, Comecer, Syntegon, Airex, TAILIN, Extract Technology, Fedegari, Optima Pharma, Esco, Hosokawa Micron, IsoTech Design |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |