What is Global Press-Fit Connectors Market?

The Global Press-Fit Connectors Market is a dynamic and evolving sector within the electronics industry, characterized by its innovative approach to connecting electronic components without the need for soldering. These connectors are designed to be pressed into a printed circuit board (PCB) to establish a reliable electrical connection. This method offers several advantages, including improved mechanical stability, reduced thermal stress, and enhanced electrical performance. The market for press-fit connectors is driven by the increasing demand for high-performance electronic devices across various industries, including automotive, aerospace, and consumer electronics. As technology continues to advance, the need for efficient and reliable connectors becomes more critical, propelling the growth of this market. Additionally, the trend towards miniaturization and the integration of more functions into smaller devices further fuels the demand for press-fit connectors, as they offer a compact and efficient solution. The global market is also influenced by the growing emphasis on sustainability and the reduction of electronic waste, as press-fit connectors can be easily removed and reused, aligning with the principles of a circular economy. Overall, the Global Press-Fit Connectors Market is poised for continued growth as it adapts to the evolving needs of the electronics industry.

Brass Connecter, Stainless Steel Connecter in the Global Press-Fit Connectors Market:

In the realm of the Global Press-Fit Connectors Market, brass and stainless steel connectors play pivotal roles, each offering unique benefits tailored to specific applications. Brass connectors are renowned for their excellent electrical conductivity, making them a popular choice in applications where efficient signal transmission is paramount. Brass, an alloy primarily composed of copper and zinc, is not only conductive but also resistant to corrosion, which enhances its durability in various environments. This makes brass connectors ideal for use in automotive electronics, where exposure to harsh conditions is common. Additionally, brass connectors are relatively easy to manufacture and can be produced in complex shapes, allowing for versatility in design and application. On the other hand, stainless steel connectors are celebrated for their exceptional strength and resistance to corrosion, even in extreme conditions. Stainless steel, an alloy known for its robustness, is often used in applications where mechanical stress and environmental factors are significant concerns. In the aerospace industry, for example, stainless steel connectors are favored for their ability to withstand high temperatures and pressures, ensuring reliable performance in critical systems. Furthermore, stainless steel connectors are often used in electronic products that require a high degree of reliability and longevity, as they can endure repeated cycles of connection and disconnection without degradation. The choice between brass and stainless steel connectors in the Global Press-Fit Connectors Market is largely determined by the specific requirements of the application, including factors such as electrical conductivity, mechanical strength, and environmental conditions. As the market continues to evolve, manufacturers are constantly innovating to enhance the performance and versatility of these connectors, ensuring they meet the diverse needs of modern electronic systems. The ongoing development of new materials and manufacturing techniques further expands the possibilities for brass and stainless steel connectors, enabling them to address emerging challenges in the electronics industry. Overall, both brass and stainless steel connectors are integral components of the Global Press-Fit Connectors Market, each offering distinct advantages that cater to the varied demands of different sectors.

Automotive Electronics, Electronic Product, Aerospace, Other in the Global Press-Fit Connectors Market:

The Global Press-Fit Connectors Market finds extensive application across various sectors, including automotive electronics, electronic products, aerospace, and others, each benefiting from the unique advantages these connectors offer. In the automotive electronics sector, press-fit connectors are crucial for ensuring reliable connections in systems such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The ability of press-fit connectors to withstand vibrations and thermal cycling makes them ideal for the demanding conditions of automotive environments. Moreover, as vehicles become increasingly electrified and connected, the need for robust and efficient connectors continues to grow, driving the adoption of press-fit technology. In the realm of electronic products, press-fit connectors are widely used in consumer electronics, telecommunications equipment, and computing devices. Their compact size and high reliability make them suitable for applications where space is limited, and performance is critical. As electronic devices become more sophisticated and feature-rich, the demand for connectors that can support high-speed data transmission and power delivery increases, further bolstering the market for press-fit connectors. In the aerospace industry, press-fit connectors are employed in avionics, communication systems, and control systems, where reliability and performance are paramount. The harsh conditions of aerospace environments, including extreme temperatures and pressures, necessitate connectors that can maintain integrity and functionality under stress. Press-fit connectors, with their robust design and resistance to environmental factors, are well-suited for these applications. Beyond these sectors, press-fit connectors are also utilized in industrial machinery, medical devices, and renewable energy systems, where their ease of installation and maintenance, coupled with their ability to provide secure and stable connections, offer significant advantages. As industries continue to innovate and integrate more advanced technologies, the role of press-fit connectors in facilitating reliable and efficient connections becomes increasingly important, underscoring their value across diverse applications.

Global Press-Fit Connectors Market Outlook:

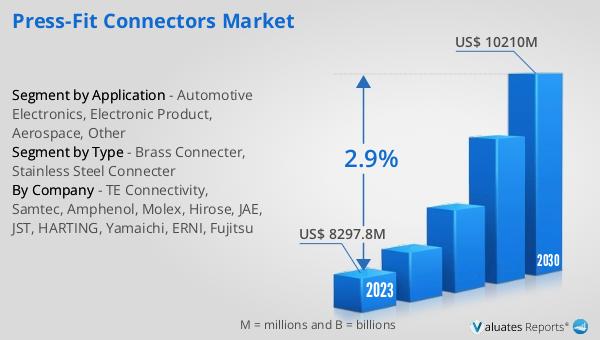

The global market for Press-Fit Connectors was valued at $8,805 million in 2024 and is anticipated to expand to a revised size of $10,750 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% over the forecast period. This steady growth trajectory underscores the increasing demand for press-fit connectors across various industries, driven by the need for reliable and efficient connectivity solutions in an era of rapid technological advancement. The market's expansion is supported by the continuous innovation in connector technology, which enhances performance and broadens the scope of applications. Notably, the global market is dominated by the top five manufacturers, who collectively hold a market share exceeding 60%. This concentration of market power highlights the competitive landscape, where leading companies leverage their expertise and resources to maintain a strong foothold. These manufacturers are at the forefront of developing cutting-edge solutions that cater to the evolving needs of industries such as automotive, aerospace, and consumer electronics. As the market continues to grow, the emphasis on sustainability and the reduction of electronic waste further propels the adoption of press-fit connectors, which align with the principles of a circular economy by offering reusable and easily removable solutions. Overall, the Global Press-Fit Connectors Market is poised for sustained growth, driven by technological advancements and the increasing demand for high-performance connectivity solutions.

| Report Metric | Details |

| Report Name | Press-Fit Connectors Market |

| Accounted market size in year | US$ 8805 million |

| Forecasted market size in 2031 | US$ 10750 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TE Connectivity, Samtec, Amphenol, Molex, Hirose, JAE, JST, HARTING, Yamaichi, ERNI, Fujitsu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |