What is Global Laser Direct Imagers Market?

The Global Laser Direct Imagers Market is a specialized segment within the broader electronics and semiconductor industry, focusing on the production and application of laser direct imaging (LDI) technology. This technology is pivotal in the manufacturing of printed circuit boards (PCBs), which are essential components in virtually all electronic devices. Laser direct imagers use laser beams to directly transfer circuit patterns onto a photoresist-coated substrate, eliminating the need for traditional photomasks. This process enhances precision and reduces production time, making it highly desirable for manufacturers aiming for efficiency and accuracy. The market is driven by the increasing demand for miniaturized and complex electronic devices, which require advanced PCBs. Additionally, the rise in consumer electronics, automotive electronics, and telecommunications sectors further fuels the demand for laser direct imagers. As technology continues to evolve, the market is expected to witness innovations that enhance imaging speed, resolution, and cost-effectiveness. The global market for laser direct imagers is characterized by a competitive landscape with several key players striving to offer cutting-edge solutions to meet the growing needs of various industries. This market is poised for growth as industries continue to seek advanced manufacturing solutions.

Polygon Mirror 365nm, DMD 405nm in the Global Laser Direct Imagers Market:

Polygon Mirror 365nm and DMD 405nm are two critical technologies within the Global Laser Direct Imagers Market, each offering unique advantages for PCB manufacturing. The Polygon Mirror 365nm technology utilizes a rotating polygon mirror to direct a laser beam across the substrate. This method is known for its high-speed imaging capabilities, making it suitable for large-scale production environments where efficiency is paramount. The 365nm wavelength is particularly effective for fine-line imaging, allowing manufacturers to achieve high-resolution patterns necessary for advanced PCBs. This technology is often favored in applications where precision and speed are critical, such as in the production of high-density interconnect (HDI) PCBs. On the other hand, DMD 405nm technology employs a digital micromirror device (DMD) to project the laser beam onto the substrate. This approach offers flexibility in patterning, as the DMD can rapidly switch between different patterns without the need for physical masks. The 405nm wavelength is well-suited for a variety of photoresist materials, providing versatility in manufacturing processes. DMD technology is particularly advantageous in prototyping and small-batch production, where quick turnaround times and adaptability are essential. Both technologies play a crucial role in the Global Laser Direct Imagers Market, catering to different manufacturing needs and preferences. As the demand for more complex and miniaturized electronic devices grows, these technologies are expected to evolve, offering even greater precision and efficiency. Manufacturers are continually exploring ways to enhance the capabilities of Polygon Mirror 365nm and DMD 405nm technologies, aiming to meet the ever-increasing demands of the electronics industry. The choice between these technologies often depends on specific production requirements, such as volume, complexity, and desired turnaround time. As such, they represent the cutting-edge of PCB manufacturing technology, driving innovation and efficiency in the industry.

Standard and HDI PCB, Thick-Copper and Ceramic PCB, Oversized PCB, Solder Mask in the Global Laser Direct Imagers Market:

The Global Laser Direct Imagers Market finds extensive application across various types of PCBs, including Standard and HDI PCBs, Thick-Copper and Ceramic PCBs, Oversized PCBs, and Solder Masks. Standard and HDI PCBs are the backbone of modern electronics, used in everything from smartphones to automotive systems. Laser direct imaging technology is crucial in the production of these PCBs, as it allows for the precise and efficient transfer of intricate circuit patterns. HDI PCBs, in particular, benefit from LDI technology due to their complex multi-layer structures and fine-line requirements. Thick-Copper and Ceramic PCBs are used in high-power applications where thermal management is critical. The ability of laser direct imagers to handle thick copper layers and ceramic substrates with precision makes them indispensable in the production of these specialized PCBs. Oversized PCBs, often used in industrial and large-scale applications, also benefit from LDI technology. The ability to accurately image large substrates without the need for multiple exposures or alignments enhances production efficiency and reduces the potential for errors. Solder masks, which protect the PCB and prevent solder bridges, are another area where laser direct imaging is invaluable. The precision of LDI technology ensures that solder masks are applied accurately, enhancing the reliability and performance of the final product. Overall, the Global Laser Direct Imagers Market plays a vital role in the production of a wide range of PCBs, each with its unique requirements and challenges. As electronic devices continue to evolve, the demand for advanced PCBs and, consequently, laser direct imaging technology is expected to grow. Manufacturers are continually seeking ways to improve the capabilities of LDI technology to meet the diverse needs of the electronics industry.

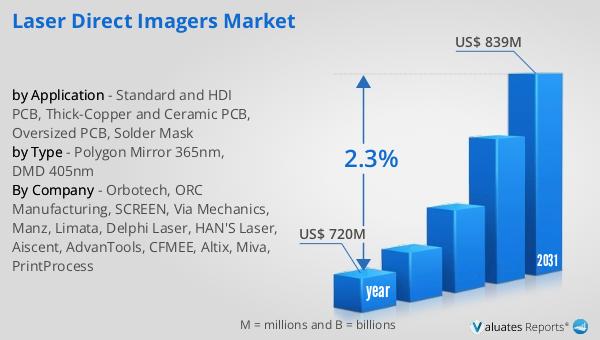

Global Laser Direct Imagers Market Outlook:

In 2024, the global market for Laser Direct Imagers was valued at approximately $720 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $839 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 2.3% over the forecast period. The steady increase in market size reflects the rising demand for advanced PCB manufacturing technologies across various industries. As electronic devices become more complex and miniaturized, the need for precise and efficient imaging solutions becomes increasingly critical. The growth in the Laser Direct Imagers Market is driven by several factors, including advancements in technology, increasing adoption in emerging markets, and the continuous evolution of consumer electronics, automotive, and telecommunications sectors. As manufacturers strive to meet the demands of these rapidly changing industries, the market for laser direct imagers is expected to continue its upward trajectory. The competitive landscape of the market is characterized by innovation and the development of new technologies that enhance imaging speed, resolution, and cost-effectiveness. As the market evolves, companies are likely to focus on expanding their product portfolios and improving their offerings to capture a larger share of this growing market.

| Report Metric | Details |

| Report Name | Laser Direct Imagers Market |

| Accounted market size in year | US$ 720 million |

| Forecasted market size in 2031 | US$ 839 million |

| CAGR | 2.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Orbotech, ORC Manufacturing, SCREEN, Via Mechanics, Manz, Limata, Delphi Laser, HAN'S Laser, Aiscent, AdvanTools, CFMEE, Altix, Miva, PrintProcess |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |