What is Global Bump Photoresist Market?

The Global Bump Photoresist Market is a specialized segment within the broader photoresist industry, focusing on materials used in semiconductor manufacturing. Photoresists are light-sensitive materials used to form patterns on semiconductor wafers, which are essential in creating integrated circuits and other microelectronic devices. The "bump" in bump photoresist refers to the tiny raised areas on a semiconductor wafer that facilitate connections between the chip and its packaging. These bumps are crucial for ensuring efficient electrical connections and are a key component in advanced packaging technologies like flip-chip and wafer-level packaging. The global market for bump photoresist is driven by the increasing demand for smaller, more powerful electronic devices, which require advanced semiconductor manufacturing techniques. As technology continues to evolve, the need for high-performance photoresists that can support finer resolutions and more complex patterns is growing. This market is characterized by rapid technological advancements, with companies investing heavily in research and development to create photoresists that meet the stringent requirements of modern semiconductor manufacturing. The global bump photoresist market is poised for significant growth as the demand for advanced electronic devices continues to rise.

Positive-Type Bump Photoresist, Negative-Type Bump Photoresist in the Global Bump Photoresist Market:

Positive-type bump photoresist and negative-type bump photoresist are two main categories within the bump photoresist market, each with distinct characteristics and applications. Positive-type bump photoresist becomes soluble when exposed to light, allowing the exposed areas to be washed away during the development process. This type of photoresist is favored for its ability to produce highly precise and intricate patterns, making it ideal for applications requiring fine detail and accuracy. Positive-type photoresists are commonly used in the production of microelectronic devices where precision is paramount. They are particularly effective in creating the intricate patterns needed for advanced semiconductor devices, where even the slightest deviation can impact performance. On the other hand, negative-type bump photoresist works in the opposite manner. When exposed to light, the areas of the photoresist that are illuminated become insoluble, while the unexposed areas are washed away. This type of photoresist is known for its robustness and ability to create thicker patterns, which are essential in certain applications. Negative-type photoresists are often used in applications where durability and thickness are more critical than fine detail. They are particularly useful in creating the bumps on semiconductor wafers that facilitate connections in advanced packaging technologies. Both positive and negative-type bump photoresists play crucial roles in the semiconductor manufacturing process, each offering unique advantages that cater to different needs within the industry. The choice between positive and negative-type photoresist depends on the specific requirements of the application, including the desired pattern resolution, thickness, and durability. As the semiconductor industry continues to advance, the demand for both types of bump photoresists is expected to grow, driven by the need for more sophisticated and efficient manufacturing processes. Companies in the bump photoresist market are continually innovating to develop new formulations that meet the evolving needs of the semiconductor industry. This includes creating photoresists that can withstand the harsh conditions of semiconductor manufacturing, such as high temperatures and chemical exposure, while still delivering the precision and performance required for modern electronic devices. The ongoing development of new photoresist technologies is essential for supporting the continued growth and advancement of the semiconductor industry.

in the Global Bump Photoresist Market:

The Global Bump Photoresist Market finds applications across a wide range of industries, primarily driven by the demand for advanced semiconductor devices. One of the primary applications of bump photoresist is in the production of integrated circuits (ICs), which are the building blocks of modern electronic devices. These circuits require precise patterning to function correctly, and bump photoresists play a crucial role in achieving the necessary level of detail and accuracy. In addition to ICs, bump photoresists are also used in the manufacturing of microelectromechanical systems (MEMS), which are tiny mechanical devices integrated with electronic components. MEMS are used in a variety of applications, including sensors, actuators, and other devices that require precise mechanical movement. The ability of bump photoresists to create intricate patterns makes them ideal for use in MEMS manufacturing, where precision is critical. Another significant application of bump photoresists is in the production of advanced packaging technologies, such as flip-chip and wafer-level packaging. These technologies are essential for creating smaller, more powerful electronic devices by allowing for more efficient connections between the semiconductor chip and its packaging. Bump photoresists are used to create the tiny bumps on the semiconductor wafer that facilitate these connections, ensuring that the final product meets the necessary performance standards. The demand for bump photoresists is also driven by the growing trend towards miniaturization in the electronics industry. As consumers continue to demand smaller, more powerful devices, manufacturers are under pressure to develop new technologies that can support these requirements. Bump photoresists are a critical component in this process, enabling the creation of smaller, more efficient semiconductor devices. The versatility of bump photoresists makes them suitable for a wide range of applications, from consumer electronics to automotive and industrial applications. As technology continues to advance, the demand for bump photoresists is expected to grow, driven by the need for more sophisticated and efficient manufacturing processes. Companies in the bump photoresist market are continually innovating to develop new formulations that meet the evolving needs of the semiconductor industry. This includes creating photoresists that can withstand the harsh conditions of semiconductor manufacturing, such as high temperatures and chemical exposure, while still delivering the precision and performance required for modern electronic devices. The ongoing development of new photoresist technologies is essential for supporting the continued growth and advancement of the semiconductor industry.

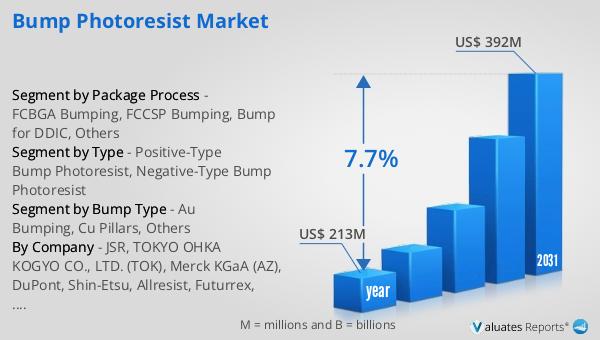

Global Bump Photoresist Market Outlook:

In 2024, the global bump photoresist market was valued at approximately $213 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach around $392 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.7% during the forecast period. The increasing demand for advanced semiconductor devices, driven by the rapid evolution of technology and the growing trend towards miniaturization, is a key factor contributing to this market expansion. As consumers continue to demand smaller, more powerful electronic devices, manufacturers are under pressure to develop new technologies that can support these requirements. Bump photoresists are a critical component in this process, enabling the creation of smaller, more efficient semiconductor devices. The versatility of bump photoresists makes them suitable for a wide range of applications, from consumer electronics to automotive and industrial applications. As technology continues to advance, the demand for bump photoresists is expected to grow, driven by the need for more sophisticated and efficient manufacturing processes. Companies in the bump photoresist market are continually innovating to develop new formulations that meet the evolving needs of the semiconductor industry. This includes creating photoresists that can withstand the harsh conditions of semiconductor manufacturing, such as high temperatures and chemical exposure, while still delivering the precision and performance required for modern electronic devices. The ongoing development of new photoresist technologies is essential for supporting the continued growth and advancement of the semiconductor industry.

| Report Metric | Details |

| Report Name | Bump Photoresist Market |

| Accounted market size in year | US$ 213 million |

| Forecasted market size in 2031 | US$ 392 million |

| CAGR | 7.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Package Process |

|

| Segment by Bump Type |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JSR, TOKYO OHKA KOGYO CO., LTD. (TOK), Merck KGaA (AZ), DuPont, Shin-Etsu, Allresist, Futurrex, KemLab™ Inc, Youngchang Chemical, Everlight Chemical, Crystal Clear Electronic Material, Kempur Microelectronics Inc, Xuzhou B & C Chemical, Sumitomo Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |