What is Global Automotive Glass Fiber Reinforced Plastic Market?

The Global Automotive Glass Fiber Reinforced Plastic (GFRP) Market is a significant segment within the automotive industry, focusing on the use of glass fiber reinforced plastics in vehicle manufacturing. These materials are known for their lightweight, high strength, and durability, making them ideal for various automotive applications. GFRP is composed of a polymer matrix reinforced with glass fibers, which enhances its mechanical properties and resistance to environmental factors. The market for these materials is driven by the increasing demand for fuel-efficient vehicles, as reducing vehicle weight is a key factor in improving fuel efficiency. Additionally, the automotive industry's shift towards electric vehicles further boosts the demand for lightweight materials like GFRP. The market is characterized by continuous innovation and development of new composite materials to meet the evolving needs of the automotive sector. As manufacturers strive to meet stringent emission regulations and consumer demand for high-performance vehicles, the adoption of GFRP is expected to grow. This market is also influenced by regional factors, with significant growth observed in regions like Asia-Pacific, Europe, and North America, where automotive production and innovation are prominent. Overall, the Global Automotive GFRP Market plays a crucial role in advancing automotive technology and sustainability.

Thermosetting Composites, Thermoplastic Composites in the Global Automotive Glass Fiber Reinforced Plastic Market:

Thermosetting composites and thermoplastic composites are two primary categories within the Global Automotive Glass Fiber Reinforced Plastic Market, each offering distinct properties and applications. Thermosetting composites are made from a polymer matrix that irreversibly cures, providing excellent thermal stability, chemical resistance, and structural integrity. These composites are typically used in applications where high strength and durability are required, such as in automotive body panels and structural components. The curing process involves a chemical reaction that forms a rigid, cross-linked structure, making thermosetting composites ideal for parts that need to withstand high temperatures and harsh environmental conditions. Common thermosetting resins used in automotive applications include epoxy, polyester, and vinyl ester, each offering unique benefits in terms of performance and cost. On the other hand, thermoplastic composites are made from a polymer matrix that can be repeatedly melted and reformed, offering advantages in terms of recyclability and ease of processing. These composites are gaining popularity in the automotive industry due to their ability to be reshaped and reused, aligning with the industry's push towards sustainability and circular economy practices. Thermoplastic composites are often used in applications where flexibility, impact resistance, and lightweight properties are essential, such as in interior components and non-structural parts. The ability to mold these materials into complex shapes and integrate them with other materials makes them highly versatile for automotive design and manufacturing. The choice between thermosetting and thermoplastic composites in automotive applications depends on various factors, including the specific performance requirements, cost considerations, and manufacturing processes. Thermosetting composites are often preferred for high-performance applications where long-term durability and resistance to extreme conditions are critical. In contrast, thermoplastic composites offer advantages in terms of production efficiency, recyclability, and adaptability to design changes. As the automotive industry continues to evolve, the demand for both types of composites is expected to grow, driven by the need for innovative materials that enhance vehicle performance, safety, and sustainability. The development of advanced composite materials, including hybrid composites that combine the benefits of both thermosetting and thermoplastic matrices, is an area of active research and innovation. These hybrid materials aim to offer the best of both worlds, providing high strength and durability along with recyclability and ease of processing. The integration of advanced manufacturing techniques, such as automated fiber placement and 3D printing, further expands the possibilities for using composites in automotive applications. These technologies enable the production of complex, lightweight structures with optimized performance characteristics, supporting the industry's goals of reducing vehicle weight and improving fuel efficiency. In conclusion, thermosetting and thermoplastic composites play a vital role in the Global Automotive Glass Fiber Reinforced Plastic Market, each offering unique advantages and challenges. The ongoing development of new materials and manufacturing processes continues to drive innovation in this field, supporting the automotive industry's transition towards more sustainable and efficient vehicles. As manufacturers seek to balance performance, cost, and environmental impact, the choice of composite materials will remain a critical factor in the design and production of next-generation vehicles.

Automotive Body & Roof Panels, Automotive Hood, Automotive Chassis, Interiors and Others in the Global Automotive Glass Fiber Reinforced Plastic Market:

The Global Automotive Glass Fiber Reinforced Plastic Market finds extensive usage in various automotive components, including body and roof panels, hoods, chassis, interiors, and other parts. In automotive body and roof panels, GFRP is favored for its lightweight and high-strength properties, which contribute to improved fuel efficiency and vehicle performance. These panels are designed to withstand impact and environmental stress, providing durability and safety for the vehicle's exterior. The use of GFRP in body panels also allows for greater design flexibility, enabling manufacturers to create aesthetically appealing and aerodynamically efficient vehicles. For automotive hoods, GFRP offers a combination of strength and weight reduction, which is crucial for maintaining the vehicle's balance and handling. The lightweight nature of GFRP hoods contributes to a lower center of gravity, enhancing the vehicle's stability and performance. Additionally, GFRP hoods provide excellent thermal insulation, protecting the engine compartment from external heat and reducing the risk of overheating. The material's resistance to corrosion and environmental factors ensures long-lasting performance, making it a preferred choice for automotive hoods. In the automotive chassis, GFRP is used to enhance structural integrity while minimizing weight. The chassis is a critical component that supports the entire vehicle structure, and the use of GFRP helps reduce the overall weight without compromising strength and safety. This weight reduction translates to improved fuel efficiency and reduced emissions, aligning with the industry's sustainability goals. GFRP's ability to absorb impact energy also enhances the vehicle's crashworthiness, providing additional safety for occupants. The interiors of vehicles also benefit from the use of GFRP, where the material's versatility and aesthetic appeal come into play. GFRP is used in various interior components, such as dashboards, door panels, and seat structures, offering a combination of lightweight, durability, and design flexibility. The material's ability to be molded into complex shapes allows for innovative interior designs that enhance passenger comfort and convenience. Additionally, GFRP's resistance to wear and tear ensures that interior components maintain their appearance and functionality over time. Beyond these specific applications, GFRP is used in other automotive parts, such as bumpers, spoilers, and underbody components, where its lightweight and high-strength properties provide performance and efficiency benefits. The material's adaptability to different manufacturing processes, such as injection molding and compression molding, allows for cost-effective production of complex parts. As the automotive industry continues to prioritize sustainability and performance, the use of GFRP in various vehicle components is expected to grow, driven by the need for innovative materials that meet the demands of modern automotive design and engineering.

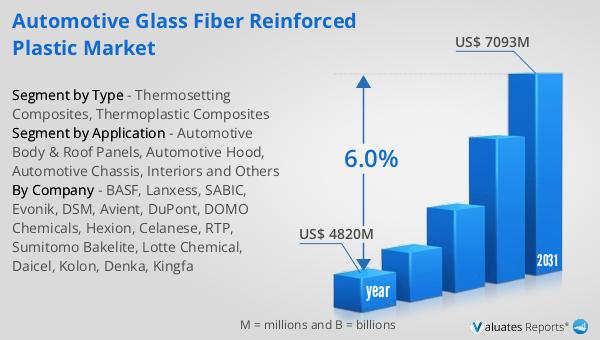

Global Automotive Glass Fiber Reinforced Plastic Market Outlook:

In 2024, the global market for Automotive Glass Fiber Reinforced Plastic was valued at approximately $4.82 billion. This market is anticipated to expand significantly, reaching an estimated size of $7.093 billion by 2031, with a compound annual growth rate (CAGR) of 6.0% during the forecast period. The market is characterized by a competitive landscape, with the top five players collectively holding over 29% of the market share. The Asia-Pacific region emerges as the largest market, accounting for about 43% of the total market share. This is followed by Europe and North America, which hold market shares of 30% and 22%, respectively. The growth in these regions is driven by the increasing demand for lightweight and fuel-efficient vehicles, as well as advancements in automotive technology. The market's expansion is also supported by the automotive industry's shift towards electric vehicles, which require innovative materials like GFRP to enhance performance and efficiency. As manufacturers continue to focus on reducing vehicle weight and improving fuel efficiency, the demand for GFRP is expected to rise, contributing to the market's growth. The competitive dynamics and regional trends within the market highlight the importance of strategic partnerships and innovation in driving future growth and success.

| Report Metric | Details |

| Report Name | Automotive Glass Fiber Reinforced Plastic Market |

| Accounted market size in year | US$ 4820 million |

| Forecasted market size in 2031 | US$ 7093 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, Lanxess, SABIC, Evonik, DSM, Avient, DuPont, DOMO Chemicals, Hexion, Celanese, RTP, Sumitomo Bakelite, Lotte Chemical, Daicel, Kolon, Denka, Kingfa |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |