What is Global Automatic Berry Harvester Market?

The Global Automatic Berry Harvester Market is a specialized segment within the agricultural machinery industry, focusing on the mechanized harvesting of berries. This market has gained traction due to the increasing demand for efficient and cost-effective harvesting solutions. Automatic berry harvesters are designed to reduce labor costs and increase productivity by automating the berry picking process. These machines are equipped with advanced technologies that allow them to gently pick berries without damaging the fruit or the plants. The market is driven by the growing consumption of berries worldwide, as they are recognized for their health benefits and versatility in culinary applications. Additionally, the shortage of agricultural labor in many regions has accelerated the adoption of automatic harvesters. Manufacturers in this market are continually innovating to improve the efficiency and effectiveness of their machines, incorporating features such as adjustable picking mechanisms and sensors to detect ripe berries. The Global Automatic Berry Harvester Market is poised for growth as more farmers seek to optimize their operations and meet the rising demand for berries. This market not only supports large-scale commercial berry farms but also smaller operations looking to scale up their production capabilities.

Half-row Harvester, Full-row Harvester in the Global Automatic Berry Harvester Market:

In the Global Automatic Berry Harvester Market, two primary types of harvesters are prevalent: half-row harvesters and full-row harvesters. Each type serves a specific purpose and is chosen based on the scale of the operation and the specific needs of the farm. Half-row harvesters are designed to harvest berries from one side of the row at a time. These machines are particularly useful for smaller farms or those with limited space between rows. They offer flexibility and are often more affordable than their full-row counterparts. Half-row harvesters are equipped with mechanisms that gently shake the plants, causing ripe berries to fall into collection trays. This method minimizes damage to both the fruit and the plants, ensuring a high-quality yield. The compact design of half-row harvesters makes them ideal for navigating narrow rows and uneven terrains, which are common in smaller berry farms. On the other hand, full-row harvesters are designed to harvest berries from both sides of the row simultaneously. These machines are typically used in larger commercial operations where efficiency and speed are paramount. Full-row harvesters are equipped with advanced technologies that allow them to cover large areas quickly, significantly reducing the time and labor required for harvesting. They are often equipped with sensors and cameras to identify ripe berries, ensuring that only the best quality fruit is collected. The use of full-row harvesters can lead to substantial cost savings for large farms, as they reduce the need for manual labor and increase the speed of the harvesting process. Both half-row and full-row harvesters play a crucial role in the Global Automatic Berry Harvester Market, catering to the diverse needs of berry producers worldwide. As technology continues to advance, these machines are becoming more efficient and user-friendly, making them an attractive option for farmers looking to optimize their operations. The choice between half-row and full-row harvesters ultimately depends on the specific requirements of the farm, including the size of the operation, the type of berries being harvested, and the available budget. Regardless of the type chosen, automatic berry harvesters represent a significant advancement in agricultural technology, offering a sustainable solution to the challenges faced by modern berry producers.

Raspberry, Blueberry, Others in the Global Automatic Berry Harvester Market:

The Global Automatic Berry Harvester Market finds its application in the harvesting of various types of berries, including raspberries, blueberries, and others. Each type of berry presents unique challenges and opportunities for mechanized harvesting. Raspberries, for instance, are delicate fruits that require careful handling to avoid damage. Automatic berry harvesters designed for raspberries are equipped with gentle picking mechanisms that minimize bruising and ensure the fruit remains intact. These machines are often adjustable to accommodate different varieties of raspberries, which can vary in size and firmness. The use of automatic harvesters in raspberry production can significantly reduce labor costs and increase efficiency, making it an attractive option for both small and large-scale producers. Blueberries, on the other hand, are more robust and can withstand more aggressive harvesting techniques. Automatic berry harvesters for blueberries are designed to efficiently collect the fruit without damaging the plants. These machines often feature adjustable settings to cater to different blueberry varieties and ripeness levels. The use of automatic harvesters in blueberry production has become increasingly popular due to the rising demand for blueberries and the need for efficient harvesting solutions. Other berries, such as blackberries and strawberries, also benefit from the use of automatic harvesters. These machines are designed to handle the specific characteristics of each type of berry, ensuring that the fruit is collected efficiently and with minimal damage. The versatility of automatic berry harvesters makes them suitable for a wide range of berry types, allowing producers to optimize their operations and meet the growing demand for berries. The Global Automatic Berry Harvester Market continues to evolve as manufacturers develop new technologies and features to improve the efficiency and effectiveness of their machines. As the demand for berries continues to rise, the adoption of automatic harvesters is expected to increase, providing a sustainable solution to the challenges faced by berry producers worldwide.

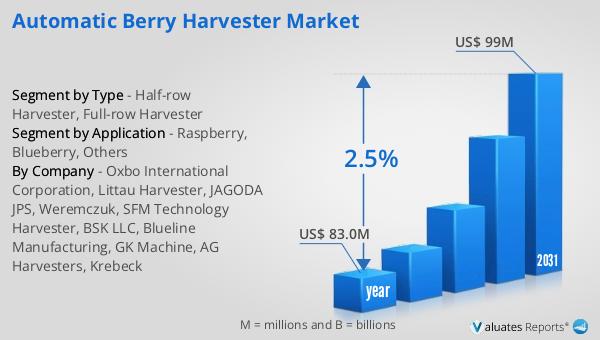

Global Automatic Berry Harvester Market Outlook:

In 2024, the global market for Automatic Berry Harvester was valued at approximately $83 million. This market is anticipated to grow steadily, reaching an estimated value of $99 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.5% over the forecast period. The steady increase in market size reflects the growing demand for efficient and cost-effective harvesting solutions in the agricultural sector. Automatic berry harvesters are becoming increasingly popular among berry producers due to their ability to reduce labor costs and increase productivity. The market's growth is driven by several factors, including the rising consumption of berries worldwide and the shortage of agricultural labor in many regions. As more farmers seek to optimize their operations and meet the growing demand for berries, the adoption of automatic harvesters is expected to increase. Manufacturers in this market are continually innovating to improve the efficiency and effectiveness of their machines, incorporating advanced technologies and features to meet the diverse needs of berry producers. The Global Automatic Berry Harvester Market is poised for growth as more farmers recognize the benefits of mechanized harvesting and seek to optimize their operations.

| Report Metric | Details |

| Report Name | Automatic Berry Harvester Market |

| Accounted market size in year | US$ 83.0 million |

| Forecasted market size in 2031 | US$ 99 million |

| CAGR | 2.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Oxbo International Corporation, Littau Harvester, JAGODA JPS, Weremczuk, SFM Technology Harvester, BSK LLC, Blueline Manufacturing, GK Machine, AG Harvesters, Krebeck |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |