What is Global Absolute Linear Encoders Market?

The Global Absolute Linear Encoders Market refers to the worldwide industry focused on the production and distribution of absolute linear encoders. These devices are essential in providing precise position feedback in various applications, ensuring accuracy and efficiency in operations. Unlike incremental encoders, absolute linear encoders provide a unique position value for each point along their path, which means they can determine the exact position without needing a reference point. This feature is particularly valuable in industries where precision is critical, such as manufacturing, robotics, and automation. The market for these encoders is driven by the increasing demand for automation and precision in industrial processes. As industries continue to evolve and adopt more advanced technologies, the need for reliable and accurate position feedback systems like absolute linear encoders becomes more pronounced. The market is characterized by a diverse range of products, catering to different industry needs and specifications, and is supported by ongoing technological advancements that enhance the performance and capabilities of these devices. The global reach of this market indicates its significance across various regions, reflecting the universal need for precision and efficiency in modern industrial applications.

Mechanical, Optical, Magnetic in the Global Absolute Linear Encoders Market:

In the Global Absolute Linear Encoders Market, three primary technologies are utilized: mechanical, optical, and magnetic. Each of these technologies offers unique advantages and is suited to different applications, contributing to the versatility and adaptability of absolute linear encoders in various industries. Mechanical encoders are among the oldest types of encoders and rely on physical contact to determine position. They typically use a sliding contact or a wiper that moves along a resistive track. While they are generally more affordable, mechanical encoders can suffer from wear and tear over time, which may affect their accuracy and lifespan. However, they are still widely used in applications where cost is a significant consideration and where the environment is not too harsh. Optical encoders, on the other hand, use light to determine position. They consist of a light source, a coded disk, and a photodetector. As the disk moves, the light is interrupted in a pattern that the photodetector reads to determine position. Optical encoders are known for their high accuracy and resolution, making them ideal for applications requiring precise measurements. They are commonly used in industries such as robotics, CNC machinery, and aerospace, where precision is paramount. However, optical encoders can be sensitive to dust and other contaminants, which can affect their performance. Magnetic encoders use magnetic fields to determine position. They consist of a magnetic scale and a sensor that detects changes in the magnetic field as the scale moves. Magnetic encoders are highly durable and can operate in harsh environments, making them suitable for applications in industries such as automotive and heavy machinery. They are less susceptible to dust and other contaminants compared to optical encoders, which enhances their reliability in challenging conditions. Additionally, magnetic encoders can provide absolute position feedback even in the event of a power loss, which is a significant advantage in certain applications. Each of these technologies has its own set of strengths and weaknesses, and the choice of encoder technology depends on the specific requirements of the application, such as the level of precision needed, the operating environment, and budget constraints. The diversity of technologies available in the Global Absolute Linear Encoders Market ensures that there is a suitable solution for virtually any application, supporting the growing demand for precision and efficiency in modern industrial processes.

Elevator, NC Machine Tool, Textile Machinery, Others in the Global Absolute Linear Encoders Market:

The Global Absolute Linear Encoders Market finds applications in various sectors, including elevators, NC machine tools, textile machinery, and others. In the elevator industry, absolute linear encoders are crucial for ensuring the precise positioning of the elevator car. They provide accurate feedback on the car's position, which is essential for smooth and safe operation. By using absolute linear encoders, elevator systems can achieve better control and efficiency, reducing energy consumption and improving passenger comfort. In NC (Numerical Control) machine tools, absolute linear encoders play a vital role in providing precise position feedback for the machine's moving parts. This precision is critical for achieving the high levels of accuracy required in modern manufacturing processes. By ensuring that the machine's tools are positioned correctly, absolute linear encoders help improve the quality of the finished product and reduce waste. In the textile machinery industry, absolute linear encoders are used to control the position of various machine components, such as looms and spindles. This precise control is essential for maintaining the quality and consistency of the textile products being produced. By providing accurate position feedback, absolute linear encoders help optimize the performance of textile machinery, leading to increased productivity and reduced downtime. Beyond these specific industries, absolute linear encoders are also used in a wide range of other applications, including robotics, medical equipment, and packaging machinery. In robotics, for example, absolute linear encoders provide the precise position feedback needed for accurate movement and control. This precision is essential for tasks such as assembly, welding, and material handling, where even small errors can lead to significant problems. In medical equipment, absolute linear encoders are used to ensure the accurate positioning of components, such as in imaging systems and surgical robots. This accuracy is critical for patient safety and the effectiveness of medical procedures. In packaging machinery, absolute linear encoders help ensure the precise positioning of components, such as conveyor belts and cutting tools, which is essential for maintaining the quality and efficiency of the packaging process. Overall, the Global Absolute Linear Encoders Market plays a crucial role in supporting a wide range of industries by providing the precision and accuracy needed for modern industrial processes.

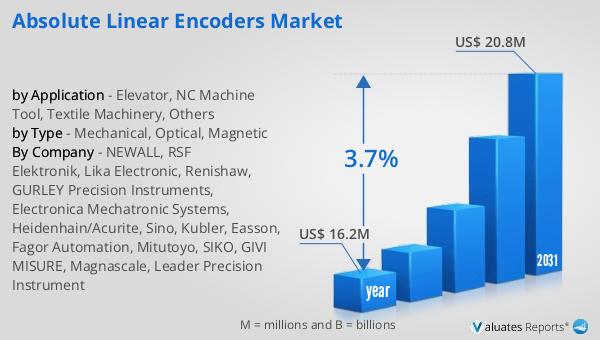

Global Absolute Linear Encoders Market Outlook:

In 2024, the worldwide market for Absolute Linear Encoders was valued at approximately $16.2 million. This market is anticipated to expand, reaching an estimated size of $20.8 million by the year 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.7% over the forecast period. The steady increase in market size reflects the growing demand for precision and automation across various industries. As businesses continue to seek ways to enhance efficiency and accuracy in their operations, the need for reliable position feedback systems like absolute linear encoders becomes increasingly important. This market growth is indicative of the broader trend towards automation and technological advancement in industrial processes. The projected expansion of the market underscores the significance of absolute linear encoders in supporting these developments. By providing precise position feedback, these devices enable industries to achieve higher levels of accuracy and efficiency, ultimately contributing to improved productivity and reduced operational costs. The anticipated growth in the Global Absolute Linear Encoders Market highlights the ongoing evolution of industrial technologies and the critical role that these devices play in facilitating this progress.

| Report Metric | Details |

| Report Name | Absolute Linear Encoders Market |

| Accounted market size in year | US$ 16.2 million |

| Forecasted market size in 2031 | US$ 20.8 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NEWALL, RSF Elektronik, Lika Electronic, Renishaw, GURLEY Precision Instruments, Electronica Mechatronic Systems, Heidenhain/Acurite, Sino, Kubler, Easson, Fagor Automation, Mitutoyo, SIKO, GIVI MISURE, Magnascale, Leader Precision Instrument |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |