What is Global Mixed Xylene Market?

The Global Mixed Xylene Market is a significant segment within the petrochemical industry, primarily driven by its versatile applications and demand across various sectors. Mixed xylene is a colorless, flammable liquid composed of a mixture of xylene isomers, including ortho-xylene, meta-xylene, and para-xylene, along with ethylbenzene. It is derived from crude oil and is a vital component in the production of several chemicals and materials. The market for mixed xylene is influenced by factors such as industrial growth, technological advancements, and the increasing need for solvents and raw materials in manufacturing processes. The demand for mixed xylene is particularly high in regions with robust industrial activities, such as Asia-Pacific, North America, and Europe. The market's growth is also supported by the rising consumption of paraxylene, which is used to produce polyethylene terephthalate (PET) for packaging and textiles. Additionally, the market benefits from the expansion of the automotive and construction industries, which utilize mixed xylene in various applications. Overall, the Global Mixed Xylene Market is poised for steady growth, driven by its essential role in numerous industrial processes and the continuous development of end-use industries.

Solvent Grade, Isomer Grade in the Global Mixed Xylene Market:

In the Global Mixed Xylene Market, two primary grades are distinguished: Solvent Grade and Isomer Grade. Solvent Grade mixed xylene is predominantly used as a solvent in various industrial applications due to its excellent solvency properties. It is widely employed in the production of paints, coatings, adhesives, and inks, where it acts as a medium to dissolve other substances and facilitate the application process. The demand for Solvent Grade mixed xylene is driven by the growth of the construction and automotive industries, which require high-quality paints and coatings for infrastructure and vehicle manufacturing. Additionally, it is used in the formulation of cleaning agents and degreasers, making it an essential component in maintenance and cleaning operations across different sectors. On the other hand, Isomer Grade mixed xylene is primarily utilized in the production of individual xylene isomers, such as paraxylene, orthoxylene, and metaxylene. Paraxylene is the most sought-after isomer, as it serves as a precursor for the production of terephthalic acid and dimethyl terephthalate, which are essential in manufacturing polyethylene terephthalate (PET) plastics and polyester fibers. The demand for paraxylene is driven by the packaging and textile industries, where PET is extensively used for making bottles, containers, and synthetic fibers. Orthoxylene is used in the production of phthalic anhydride, a key ingredient in the manufacture of plasticizers, resins, and dyes. Metaxylene, although less in demand compared to its counterparts, finds applications in the production of isophthalic acid, which is used in high-performance polymers and resins. The Isomer Grade mixed xylene market is influenced by the growing demand for these individual isomers in various end-use industries, including packaging, textiles, and plastics. The production and supply of both Solvent Grade and Isomer Grade mixed xylene are closely linked to the availability of crude oil and the efficiency of refining processes. Technological advancements in refining and separation techniques have enhanced the production capabilities of mixed xylene, ensuring a steady supply to meet the increasing demand. Furthermore, the market dynamics are shaped by the fluctuations in crude oil prices, environmental regulations, and the development of alternative materials and processes. Companies operating in the Global Mixed Xylene Market are focusing on optimizing their production processes, expanding their product portfolios, and exploring new applications to maintain a competitive edge. The market is characterized by the presence of several key players, including multinational corporations and regional manufacturers, who are actively engaged in research and development activities to enhance the quality and performance of mixed xylene products. Overall, the Solvent Grade and Isomer Grade segments of the Global Mixed Xylene Market play a crucial role in supporting various industrial applications and driving the growth of related industries.

Used as a Solvent and Raw Material of Paraxylene, Used as a Solvent in the Printing, Rubber, Leather Industries and Aviation Gasoline Additive, Used in the Production of Polymers, Used as a Cleaning Agent for Steel in the Global Mixed Xylene Market:

The Global Mixed Xylene Market finds extensive usage across various industries due to its versatile properties and applications. One of the primary uses of mixed xylene is as a solvent and raw material for paraxylene production. Paraxylene is a crucial component in the manufacture of polyethylene terephthalate (PET), which is widely used in the packaging industry for making bottles, containers, and films. The demand for PET is driven by the increasing consumption of packaged goods and beverages, making mixed xylene an essential raw material in the packaging sector. Additionally, mixed xylene is used as a solvent in the printing, rubber, and leather industries. In the printing industry, it acts as a solvent for inks, ensuring smooth application and quick drying. In the rubber industry, mixed xylene is used as a solvent in the production of synthetic rubber, which is essential for manufacturing tires and other rubber products. The leather industry utilizes mixed xylene as a solvent in the tanning and finishing processes, enhancing the quality and durability of leather goods. Furthermore, mixed xylene serves as an additive in aviation gasoline, improving the fuel's performance and efficiency. The aviation industry relies on high-quality fuels to ensure the safe and efficient operation of aircraft, and mixed xylene plays a vital role in meeting these requirements. In the production of polymers, mixed xylene is used as a feedstock for manufacturing various types of plastics and resins. The demand for polymers is driven by their widespread use in packaging, construction, automotive, and electronics industries. Mixed xylene's role as a feedstock ensures a steady supply of raw materials for polymer production, supporting the growth of these industries. Additionally, mixed xylene is used as a cleaning agent for steel, where it helps remove grease, oil, and other contaminants from metal surfaces. The steel industry relies on effective cleaning agents to maintain the quality and integrity of steel products, and mixed xylene's solvency properties make it an ideal choice for this application. Overall, the Global Mixed Xylene Market plays a crucial role in supporting various industrial applications, driving the growth of related industries, and meeting the increasing demand for high-quality products and materials.

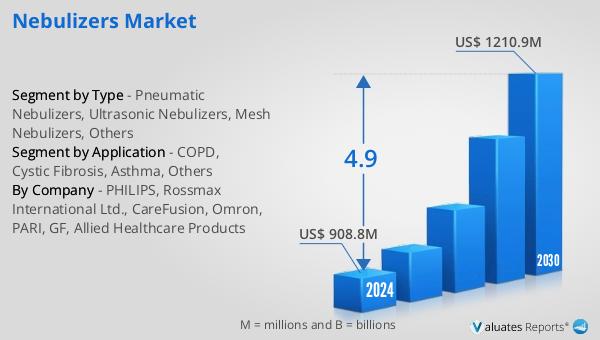

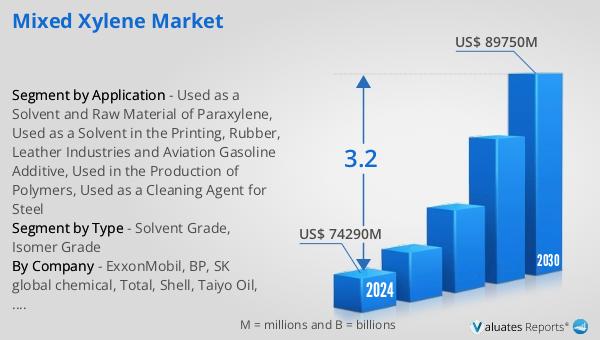

Global Mixed Xylene Market Outlook:

In 2024, the global market size of Mixed Xylene was valued at approximately USD 76,430 million, with projections indicating it could reach around USD 94,990 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.2% during the forecast period from 2025 to 2031. The market is characterized by the presence of several key players, with ExxonMobil, BP, Sinopec, CNPC, and CNOOC being the top five manufacturers in the industry. These companies collectively hold about 25% of the market share, highlighting their significant influence and competitive positioning within the market. The growth of the Global Mixed Xylene Market is driven by the increasing demand for mixed xylene in various industrial applications, including its use as a solvent, raw material for paraxylene production, and additive in aviation gasoline. The market dynamics are influenced by factors such as industrial growth, technological advancements, and fluctuations in crude oil prices. Companies operating in the market are focusing on optimizing their production processes, expanding their product portfolios, and exploring new applications to maintain a competitive edge. The market's growth is also supported by the expansion of end-use industries, such as packaging, textiles, and automotive, which rely on mixed xylene for their manufacturing processes. Overall, the Global Mixed Xylene Market is poised for steady growth, driven by its essential role in numerous industrial processes and the continuous development of end-use industries.

| Report Metric | Details |

| Report Name | Mixed Xylene Market |

| CAGR | 3.2% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ExxonMobil, BP, SK global chemical, Total, Shell, Taiyo Oil, Idemitsu, COSMO OIL, Citgo, Valero, GS Caltex, PEMEX, MRPL, Galp Energia, Marathon Petroleum Corporation, YNCC, YPF, LOTTE CHEMICAL, Sinopec, CNPC, CNOOC, Fujia Group, FREP, Qingdao Lidong Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |