What is Global Epoxidized Soybean Oil Market?

The Global Epoxidized Soybean Oil (ESBO) Market is a significant segment within the broader chemical industry, primarily driven by its versatile applications and eco-friendly nature. Epoxidized soybean oil is derived from soybean oil through an epoxidation process, which involves the conversion of carbon-carbon double bonds into epoxide groups. This transformation enhances the oil's stability and reactivity, making it a valuable additive in various industries. ESBO is widely used as a plasticizer and stabilizer in the production of polyvinyl chloride (PVC) plastics, where it helps improve flexibility and durability while reducing the environmental impact compared to traditional phthalate-based plasticizers. Additionally, its non-toxic and biodegradable properties make it an attractive choice for manufacturers seeking sustainable alternatives. The demand for ESBO is further bolstered by the growing awareness of environmental issues and the push for greener products. As industries continue to prioritize sustainability, the Global Epoxidized Soybean Oil Market is expected to experience steady growth, driven by its applications in packaging, automotive, and consumer goods sectors, among others. This market's expansion is also supported by advancements in production technologies and increasing investments in research and development to enhance product performance and broaden its application scope.

Mode of Production: Ring Opening Polymerization, Mode of Production: Reaction with Maleic Anhydride in the Global Epoxidized Soybean Oil Market:

The production of Epoxidized Soybean Oil (ESBO) involves several methods, with Ring Opening Polymerization and Reaction with Maleic Anhydride being two notable processes. Ring Opening Polymerization is a technique that involves the opening of the epoxide ring in the soybean oil molecule, leading to the formation of polymers. This method is particularly advantageous for creating materials with specific properties, such as enhanced flexibility and thermal stability. The process begins with the epoxidation of soybean oil, where the double bonds in the oil are converted into epoxide groups. These epoxide groups are then subjected to polymerization, resulting in a network of interconnected molecules. This network structure imparts desirable mechanical and chemical properties to the final product, making it suitable for various industrial applications, including coatings, adhesives, and sealants. The versatility of Ring Opening Polymerization allows manufacturers to tailor the properties of the resulting polymers to meet specific requirements, thereby expanding the potential applications of ESBO in different sectors. On the other hand, the Reaction with Maleic Anhydride is another method used in the production of ESBO. This process involves the reaction of epoxidized soybean oil with maleic anhydride, a chemical compound known for its ability to introduce carboxylic acid groups into the oil. The reaction typically occurs under controlled conditions, where the maleic anhydride reacts with the epoxide groups in the soybean oil, resulting in the formation of a modified oil with enhanced properties. This modification process is particularly useful for improving the oil's compatibility with other materials, such as resins and polymers, thereby broadening its application range. The introduction of carboxylic acid groups enhances the oil's adhesion properties, making it an ideal additive in the production of paints, coatings, and adhesives. Additionally, the modified oil exhibits improved thermal stability and resistance to degradation, which are critical factors in applications where durability and longevity are essential. Both Ring Opening Polymerization and Reaction with Maleic Anhydride offer unique advantages in the production of Epoxidized Soybean Oil, catering to different industrial needs. The choice of production method depends on the desired properties of the final product and the specific application requirements. For instance, Ring Opening Polymerization is favored for applications that demand high flexibility and thermal stability, while Reaction with Maleic Anhydride is preferred for applications requiring enhanced adhesion and compatibility with other materials. The ability to customize the properties of ESBO through these production methods underscores its versatility and adaptability in various industries. As the demand for sustainable and environmentally friendly products continues to rise, the development and optimization of these production techniques are expected to play a crucial role in the growth of the Global Epoxidized Soybean Oil Market. Manufacturers are increasingly investing in research and development to refine these processes, improve product quality, and explore new applications, thereby driving innovation and expansion in the market.

Medical, Food, Industrial in the Global Epoxidized Soybean Oil Market:

The Global Epoxidized Soybean Oil Market finds extensive usage across various sectors, including medical, food, and industrial applications, owing to its non-toxic, biodegradable, and versatile nature. In the medical field, ESBO is primarily used as a plasticizer in the production of medical-grade PVC products, such as blood bags, tubing, and other medical devices. Its non-toxic properties make it a safer alternative to traditional phthalate-based plasticizers, which have raised health concerns due to their potential endocrine-disrupting effects. The use of ESBO in medical applications ensures that the products remain flexible and durable while minimizing the risk of harmful chemical leaching, thereby enhancing patient safety and compliance with stringent regulatory standards. In the food industry, Epoxidized Soybean Oil serves as an additive in food packaging materials, such as cling films and food wraps. Its role as a plasticizer helps improve the flexibility and strength of these materials, ensuring that they can effectively protect food products from contamination and spoilage. The non-toxic and biodegradable nature of ESBO aligns with the growing consumer demand for sustainable and environmentally friendly packaging solutions. Additionally, ESBO is used as a stabilizer in the production of food-grade PVC materials, which are employed in various food processing and handling applications. Its ability to enhance the thermal stability and resistance to degradation of these materials ensures that they can withstand the rigors of food processing environments while maintaining their integrity and performance. In the industrial sector, ESBO is widely utilized as a plasticizer and stabilizer in the production of PVC products, such as cables, flooring, and automotive components. Its ability to improve the flexibility, durability, and thermal stability of PVC materials makes it an essential additive in these applications. The use of ESBO in industrial applications is driven by the need for sustainable and environmentally friendly alternatives to traditional plasticizers, which are often associated with environmental and health concerns. The versatility of ESBO allows it to be used in a wide range of industrial applications, from construction materials to automotive parts, where its properties contribute to the overall performance and longevity of the products. The diverse applications of Epoxidized Soybean Oil in the medical, food, and industrial sectors highlight its importance as a versatile and sustainable additive. Its non-toxic and biodegradable nature makes it an attractive choice for manufacturers seeking to reduce their environmental impact and comply with regulatory standards. As industries continue to prioritize sustainability and environmental responsibility, the demand for ESBO is expected to grow, driven by its ability to enhance the performance and sustainability of various products. The ongoing development of new applications and production technologies is likely to further expand the market for Epoxidized Soybean Oil, reinforcing its position as a key player in the global chemical industry.

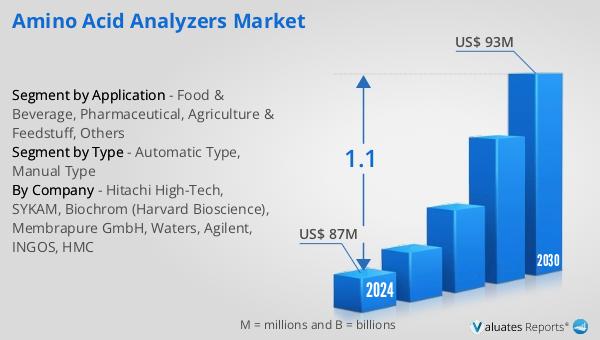

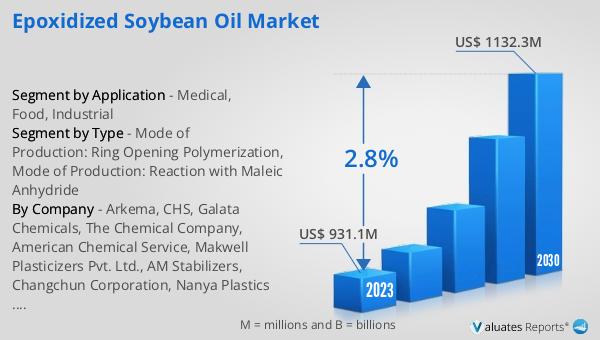

Global Epoxidized Soybean Oil Market Outlook:

In the year 2024, the global market for Epoxidized Soybean Oil was valued at approximately US$ 984 million. Projections indicate that by 2031, this market is expected to grow to around US$ 1190 million, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2025 to 2031. This growth trajectory underscores the increasing demand for ESBO across various industries, driven by its eco-friendly properties and versatile applications. Among the leading manufacturers in this industry are Arkema, Hairma Chemicals, CHS, Xinjinlong Chemical Additives, and Galata Chemicals. These top five companies collectively hold about 40% of the market share, highlighting their significant influence and competitive positioning within the market. The dominance of these manufacturers is attributed to their extensive product portfolios, strong distribution networks, and continuous investments in research and development to enhance product quality and performance. As the market continues to evolve, these companies are likely to play a pivotal role in shaping the future of the Global Epoxidized Soybean Oil Market, leveraging their expertise and resources to capitalize on emerging opportunities and address the growing demand for sustainable and environmentally friendly products.

| Report Metric | Details |

| Report Name | Epoxidized Soybean Oil Market |

| CAGR | 2.8% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Arkema, CHS, Galata Chemicals, The Chemical Company, American Chemical Service, Makwell Plasticizers Pvt. Ltd., AM Stabilizers, Changchun Corporation, Nanya Plastics Corporation, Hairma Chemicals, Hebei Jingu Plasticizer, Xinjinlong Chemical Additives, Longda Oil Technology, Puyang Chengyi Plasticizer, Baolilai Plastic Additives, Longda Chemical, Shenzhen Jianjing Plastic Additives, Shenzhen Kaiqi Chemicals, Chaohu Xiangfeng Plastic Aids, Qingzhou City East Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |