What is Global Injection Press Market?

The Global Injection Press Market refers to the industry focused on the production and sale of machines used for injection molding, a manufacturing process for producing parts by injecting molten material into a mold. These machines are essential in creating a wide range of products, from small components to large automotive parts. The market is driven by the demand for high-quality, precision-engineered products across various industries, including automotive, electronics, consumer goods, and medical devices. Injection presses are categorized based on their operational mechanisms, such as electric, hydraulic, and hybrid systems, each offering distinct advantages in terms of speed, energy efficiency, and precision. The global market is characterized by technological advancements, increasing automation, and a focus on sustainability, as manufacturers seek to reduce waste and energy consumption. As industries continue to innovate and expand, the demand for injection presses is expected to grow, driven by the need for efficient, cost-effective production solutions. The market is also influenced by regional economic conditions, regulatory standards, and the availability of raw materials, which can impact production costs and pricing strategies. Overall, the Global Injection Press Market plays a crucial role in modern manufacturing, enabling the production of diverse and complex products.

Electric, Hydraulic, Hybrid in the Global Injection Press Market:

In the Global Injection Press Market, machines are primarily categorized into three types based on their operational mechanisms: electric, hydraulic, and hybrid. Electric injection presses are known for their precision and energy efficiency. They use electric motors to drive the entire process, which allows for precise control over the molding parameters. This precision is particularly beneficial in industries where high accuracy is required, such as electronics and medical devices. Electric presses are also quieter and cleaner, as they do not require hydraulic oil, making them an environmentally friendly option. However, they can be more expensive upfront compared to hydraulic machines. Hydraulic injection presses, on the other hand, are known for their robustness and ability to handle larger molds and higher clamping forces. They use hydraulic cylinders to exert force, making them suitable for producing large parts, such as automotive components. While they may not offer the same level of precision as electric presses, they are often more cost-effective for large-scale production. Hybrid injection presses combine the best of both worlds, utilizing both electric and hydraulic systems. They offer the precision and energy efficiency of electric presses while maintaining the power and versatility of hydraulic systems. This makes them ideal for a wide range of applications, providing manufacturers with flexibility in production. The choice between electric, hydraulic, and hybrid systems depends on various factors, including the specific requirements of the production process, budget constraints, and environmental considerations. As technology continues to advance, manufacturers are increasingly adopting hybrid systems to optimize their production processes, reduce energy consumption, and improve overall efficiency. The Global Injection Press Market is thus characterized by a diverse range of machines, each offering unique benefits to meet the evolving needs of different industries.

Automotive, Medical Industry, Food & Beverage Industry, Consumer Goods Industry, Electronics & Telecom Industry, Others in the Global Injection Press Market:

The Global Injection Press Market finds extensive usage across various industries, each with specific requirements and applications. In the automotive industry, injection presses are crucial for manufacturing a wide range of components, from small interior parts to large exterior panels. The precision and efficiency of these machines enable the production of high-quality, durable parts that meet the stringent safety and performance standards of the automotive sector. In the medical industry, injection presses are used to produce medical devices and components, such as syringes, vials, and surgical instruments. The high precision and cleanliness of electric injection presses make them ideal for this industry, where accuracy and hygiene are paramount. In the food and beverage industry, injection presses are used to create packaging materials, such as bottles, caps, and containers. The ability to produce lightweight, durable, and recyclable packaging is essential for meeting consumer demands and regulatory requirements. In the consumer goods industry, injection presses are used to manufacture a wide range of products, from household items to personal care products. The versatility of these machines allows manufacturers to produce complex designs and intricate details, enhancing the aesthetic appeal and functionality of consumer goods. In the electronics and telecom industry, injection presses are used to produce components such as connectors, housings, and casings. The precision and efficiency of electric and hybrid presses are particularly beneficial in this industry, where small, intricate parts are common. Other industries, such as aerospace and construction, also utilize injection presses for various applications, highlighting the versatility and importance of these machines in modern manufacturing. Overall, the Global Injection Press Market plays a vital role in enabling the production of diverse and complex products across multiple industries, driving innovation and efficiency in manufacturing processes.

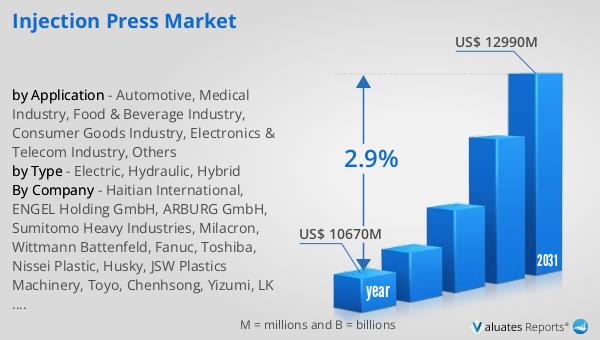

Global Injection Press Market Outlook:

The global market for Injection Press was valued at approximately $10,670 million in 2024 and is anticipated to expand to a revised size of around $12,990 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 2.9% over the forecast period. The steady increase in market size reflects the rising demand for injection presses across various industries, driven by the need for efficient and cost-effective manufacturing solutions. As industries continue to innovate and expand, the demand for high-quality, precision-engineered products is expected to grow, further fueling the market's expansion. The market's growth is also influenced by technological advancements, increasing automation, and a focus on sustainability, as manufacturers seek to reduce waste and energy consumption. Additionally, regional economic conditions, regulatory standards, and the availability of raw materials can impact production costs and pricing strategies, further shaping the market's outlook. Overall, the Global Injection Press Market is poised for steady growth, driven by the increasing demand for efficient, cost-effective production solutions across various industries.

| Report Metric | Details |

| Report Name | Injection Press Market |

| Accounted market size in year | US$ 10670 million |

| Forecasted market size in 2031 | US$ 12990 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Haitian International, ENGEL Holding GmbH, ARBURG GmbH, Sumitomo Heavy Industries, Milacron, Wittmann Battenfeld, Fanuc, Toshiba, Nissei Plastic, Husky, JSW Plastics Machinery, Toyo, Chenhsong, Yizumi, LK Technology, Cosmos Machinery, Tederic, UBE Machinery, Windsor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |