What is Stainless Steel Compression Spring - Global Market?

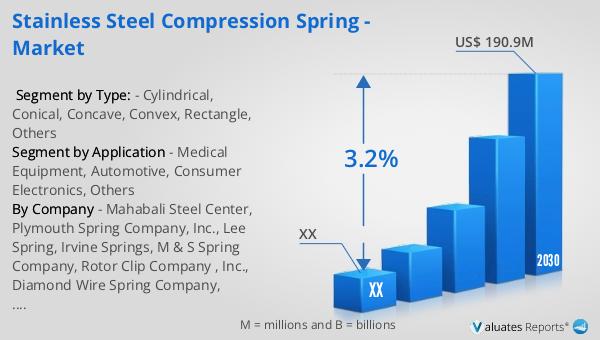

Stainless steel compression springs are essential components in various industries due to their ability to store mechanical energy when compressed. These springs are made from stainless steel, a material known for its corrosion resistance, strength, and durability, making them suitable for a wide range of applications. The global market for stainless steel compression springs is a dynamic and evolving sector, driven by the increasing demand for reliable and efficient mechanical components across different industries. In 2023, the market was valued at approximately US$ 154 million, and it is projected to grow to US$ 190.9 million by 2030, with a compound annual growth rate (CAGR) of 3.2% from 2024 to 2030. This growth is attributed to the rising adoption of stainless steel compression springs in sectors such as automotive, medical equipment, and consumer electronics, where they play a crucial role in ensuring the functionality and longevity of various devices and systems. The versatility and resilience of stainless steel compression springs make them indispensable in applications where precision and reliability are paramount. As industries continue to innovate and expand, the demand for these springs is expected to increase, further driving the market's growth.

Cylindrical, Conical, Concave, Convex, Rectangle, Others in the Stainless Steel Compression Spring - Global Market:

Stainless steel compression springs come in various shapes and designs, each tailored to meet specific application requirements. The most common types include cylindrical, conical, concave, convex, rectangular, and other specialized forms. Cylindrical springs are the most widely used due to their simple design and ease of manufacture. They provide consistent force and are ideal for applications where space is limited. Conical springs, on the other hand, are designed to provide a variable force, which is beneficial in applications requiring a gradual increase in force as the spring is compressed. This design also allows for a more compact spring when fully compressed, making it suitable for applications with limited space. Concave and convex springs are variations that offer unique force characteristics. Concave springs, also known as hourglass springs, are designed to distribute force evenly across the spring, reducing stress and increasing the spring's lifespan. Convex springs, or barrel springs, provide a more concentrated force in the center, which can be advantageous in applications requiring a focused force. Rectangular springs are less common but are used in applications where a flat profile is necessary. These springs offer a unique force distribution and are often used in specialized applications. Other forms of stainless steel compression springs include custom designs tailored to meet specific industry needs. These can include springs with varying coil diameters, wire thicknesses, and lengths to provide the exact force and compression characteristics required for a particular application. The diversity in design and application of stainless steel compression springs highlights their versatility and importance in the global market. As industries continue to evolve and demand more specialized components, the variety and customization of these springs will likely expand, further solidifying their role in modern engineering and manufacturing.

Medical Equipment, Automotive, Consumer Electronics, Others in the Stainless Steel Compression Spring - Global Market:

Stainless steel compression springs are integral to various industries, providing essential functionality in numerous applications. In the medical equipment sector, these springs are used in devices such as syringes, inhalers, and surgical instruments, where precision and reliability are critical. The corrosion resistance and durability of stainless steel make these springs ideal for medical applications, where they must withstand frequent sterilization and use. In the automotive industry, stainless steel compression springs are used in suspension systems, valve assemblies, and clutch mechanisms, among other components. Their ability to absorb shock and maintain consistent force under varying conditions makes them indispensable in ensuring vehicle safety and performance. The consumer electronics industry also relies heavily on stainless steel compression springs, using them in devices such as smartphones, laptops, and cameras. These springs provide the necessary tension and support for buttons, connectors, and other moving parts, ensuring the smooth operation of electronic devices. Other industries, such as aerospace, construction, and manufacturing, also utilize stainless steel compression springs for their unique properties and versatility. In aerospace, these springs are used in landing gear, control systems, and other critical components, where reliability and performance are paramount. In construction and manufacturing, stainless steel compression springs are used in machinery and equipment, providing the necessary force and support for various operations. The widespread use of stainless steel compression springs across these diverse industries underscores their importance and the growing demand for high-quality, reliable components in today's market.

Stainless Steel Compression Spring - Global Market Outlook:

The global market for stainless steel compression springs was valued at approximately US$ 154 million in 2023, with projections indicating a growth to US$ 190.9 million by 2030. This represents a compound annual growth rate (CAGR) of 3.2% from 2024 to 2030. Stainless steel compression springs are elastic elements that store energy through compression, making them essential components in various industries. Their ability to withstand harsh environments, resist corrosion, and maintain consistent performance under stress makes them highly sought after in sectors such as automotive, medical equipment, and consumer electronics. The market's growth is driven by the increasing demand for reliable and efficient mechanical components, as well as the ongoing innovation and expansion of industries that rely on these springs. As the global economy continues to recover and industries adapt to new challenges and opportunities, the demand for stainless steel compression springs is expected to rise, further fueling market growth. The versatility and resilience of these springs make them indispensable in applications where precision and reliability are crucial, ensuring their continued relevance and importance in the global market.

| Report Metric | Details |

| Report Name | Stainless Steel Compression Spring - Market |

| Forecasted market size in 2030 | US$ 190.9 million |

| CAGR | 3.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mahabali Steel Center, Plymouth Spring Company, Inc., Lee Spring, Irvine Springs, M & S Spring Company, Rotor Clip Company , Inc., Diamond Wire Spring Company, Springmasters Ltd, Maverick Spring Manufacturers, Metrol Springs Ltd, Vanel Tech, Argo Spring Manufacturing Co Inc, W. W. Grainger, Monroe Engineering, Howrah, Springflex Enterprises |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |