What is Soft Capsule Encapsulation Machine - Global Market?

Soft capsule encapsulation machines are specialized equipment used in the production of soft gelatin capsules, which are widely utilized in various industries for their ability to encapsulate liquids, suspensions, and semi-solids. These machines play a crucial role in the global market by providing an efficient and reliable method for producing soft capsules, which are favored for their ease of swallowing and ability to deliver precise dosages. The global market for these machines is driven by the increasing demand for soft capsules in the pharmaceutical, nutraceutical, and cosmetic industries. Soft capsule encapsulation machines are designed to automate the encapsulation process, ensuring consistent quality and high production rates. They typically consist of several components, including a gelatin melting tank, a fill material tank, a die roll system, and a drying system. The machines can be customized to produce capsules of various sizes, shapes, and colors, catering to the diverse needs of manufacturers. As the demand for soft capsules continues to grow, the market for soft capsule encapsulation machines is expected to expand, driven by technological advancements and the increasing adoption of automated manufacturing processes.

Fully-automatic, Semi-automatic in the Soft Capsule Encapsulation Machine - Global Market:

Soft capsule encapsulation machines can be categorized into fully-automatic and semi-automatic types, each offering distinct advantages and catering to different production needs. Fully-automatic soft capsule encapsulation machines are designed for high-volume production and are equipped with advanced features that allow for continuous operation with minimal human intervention. These machines are ideal for large-scale manufacturers who require consistent quality and high output rates. They are equipped with automated systems for gelatin preparation, fill material dosing, and capsule formation, ensuring precise control over the encapsulation process. The fully-automatic machines also come with integrated drying systems that streamline the production process, reducing the need for manual handling and minimizing the risk of contamination. On the other hand, semi-automatic soft capsule encapsulation machines are more suitable for small to medium-sized manufacturers or those who require flexibility in their production processes. These machines offer a balance between automation and manual control, allowing operators to adjust parameters and make real-time changes to the encapsulation process. Semi-automatic machines are often more affordable than their fully-automatic counterparts, making them an attractive option for businesses with budget constraints. They are also easier to operate and maintain, requiring less technical expertise and training. Despite their lower production capacity compared to fully-automatic machines, semi-automatic machines provide manufacturers with the ability to produce a wide range of capsule sizes and formulations, catering to niche markets and specialized applications. Both fully-automatic and semi-automatic soft capsule encapsulation machines are designed to meet stringent quality standards, ensuring that the capsules produced are of high quality and free from defects. The choice between fully-automatic and semi-automatic machines depends on various factors, including production volume, budget, and specific manufacturing requirements. As the demand for soft capsules continues to rise, manufacturers are increasingly investing in advanced encapsulation technologies to enhance their production capabilities and meet the growing needs of the market.

Pharmaceutical, Food and Beverages, Chemical, Others in the Soft Capsule Encapsulation Machine - Global Market:

Soft capsule encapsulation machines are widely used across various industries, including pharmaceuticals, food and beverages, chemicals, and others, due to their versatility and efficiency in producing soft gelatin capsules. In the pharmaceutical industry, these machines are essential for the production of soft capsules that deliver precise dosages of active pharmaceutical ingredients (APIs). Soft capsules are favored for their ability to encapsulate a wide range of formulations, including oils, suspensions, and semi-solids, making them ideal for delivering complex drug formulations. The use of soft capsule encapsulation machines in the pharmaceutical sector is driven by the increasing demand for innovative drug delivery systems and the need for patient-friendly dosage forms. In the food and beverage industry, soft capsule encapsulation machines are used to produce dietary supplements and nutraceuticals, such as vitamins, minerals, and herbal extracts. These capsules offer a convenient and effective way to deliver essential nutrients and bioactive compounds, catering to the growing consumer demand for health and wellness products. The machines enable manufacturers to produce capsules with precise dosages and consistent quality, ensuring that consumers receive the intended health benefits. In the chemical industry, soft capsule encapsulation machines are used to encapsulate various chemical compounds, providing a safe and efficient method for handling and delivering hazardous or sensitive materials. The encapsulation process helps to protect the active ingredients from environmental factors, such as moisture and light, ensuring their stability and efficacy. Additionally, soft capsules offer a convenient and controlled release mechanism, making them suitable for applications that require precise dosing and targeted delivery. Other industries, such as cosmetics and personal care, also utilize soft capsule encapsulation machines to produce products like skincare serums and essential oils. The versatility of these machines allows manufacturers to create customized formulations and innovative product offerings, catering to the diverse needs of consumers. As the demand for soft capsules continues to grow across various industries, the market for soft capsule encapsulation machines is expected to expand, driven by technological advancements and the increasing adoption of automated manufacturing processes.

Soft Capsule Encapsulation Machine - Global Market Outlook:

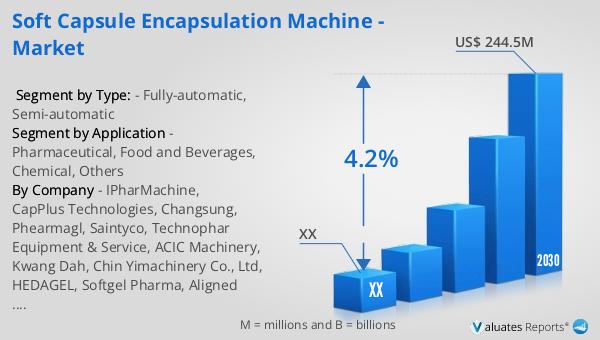

The global market for soft capsule encapsulation machines was valued at approximately $182 million in 2023 and is projected to grow to around $244.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for soft capsule encapsulation machines across various industries, driven by the need for efficient and reliable production methods. The North American market for these machines is also expected to experience significant growth during the same period, although specific figures for this region were not provided. The rising demand for soft capsules in the pharmaceutical, nutraceutical, and cosmetic industries is a key factor contributing to the market's expansion. As manufacturers seek to enhance their production capabilities and meet the growing needs of the market, investments in advanced encapsulation technologies are expected to increase. The market outlook for soft capsule encapsulation machines is positive, with technological advancements and the increasing adoption of automated manufacturing processes playing a crucial role in driving growth. As the global market continues to evolve, manufacturers will need to adapt to changing consumer preferences and regulatory requirements to remain competitive and capitalize on emerging opportunities.

| Report Metric | Details |

| Report Name | Soft Capsule Encapsulation Machine - Market |

| Forecasted market size in 2030 | US$ 244.5 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | IPharMachine, CapPlus Technologies, Changsung, Phearmagl, Saintyco, Technophar Equipment & Service, ACIC Machinery, Kwang Dah, Chin Yimachinery Co., Ltd, HEDAGEL, Softgel Pharma, Aligned Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |