What is Sludge Valve - Global Market?

Sludge valves are essential components in various industries, primarily used to control the flow of thick, viscous fluids or semi-solid materials, commonly referred to as sludge. These valves are designed to handle the challenging conditions associated with sludge, such as high pressure, abrasive materials, and potential blockages. The global market for sludge valves is driven by the increasing demand for efficient waste management solutions and the need for reliable equipment in industries like wastewater treatment, mining, and chemical processing. As urbanization and industrial activities continue to grow, the demand for effective sludge management systems is expected to rise, further propelling the market for sludge valves. These valves come in various types, each designed to meet specific operational requirements and environmental conditions. The market is characterized by a diverse range of products, including angle mud valves, quick open mud valves, pool low sludge valves, diaphragm sludge valves, and piston sludge valves, among others. Each type of valve offers unique features and benefits, catering to the specific needs of different applications and industries. As a result, the sludge valve market is poised for steady growth, driven by technological advancements and the increasing focus on sustainable and efficient waste management practices.

Angle Mud Valve, Quick Open Mud Valve, Pool Low Sludge Valve, Diaphragm Sludge Valve, Piston Sludge Valve, Others in the Sludge Valve - Global Market:

Angle mud valves are a type of sludge valve designed to handle the flow of thick, abrasive materials. These valves are typically used in applications where the flow needs to be redirected at an angle, making them ideal for systems with limited space or complex piping arrangements. The design of angle mud valves allows for efficient flow control and minimal pressure drop, ensuring optimal performance even in challenging conditions. Quick open mud valves, on the other hand, are designed for applications that require rapid opening and closing of the valve. These valves are often used in emergency situations or processes that demand quick response times, providing reliable and efficient flow control. Pool low sludge valves are specifically designed for use in swimming pools and similar environments, where the removal of sludge and debris is essential for maintaining water quality. These valves are typically easy to operate and maintain, ensuring consistent performance and minimal downtime. Diaphragm sludge valves utilize a flexible diaphragm to control the flow of sludge, providing precise flow regulation and excellent sealing capabilities. These valves are ideal for applications where leakage prevention is critical, such as in chemical processing or wastewater treatment. Piston sludge valves, meanwhile, use a piston mechanism to control the flow of sludge, offering robust performance and durability in demanding environments. These valves are often used in industries where high pressure and abrasive materials are common, such as mining or oil and gas. Other types of sludge valves include knife gate valves, pinch valves, and ball valves, each offering unique features and benefits for specific applications. Knife gate valves are designed to cut through thick sludge, providing reliable flow control in challenging conditions. Pinch valves use a flexible sleeve to control the flow, offering excellent abrasion resistance and minimal maintenance requirements. Ball valves, while not specifically designed for sludge, can be used in certain applications where precise flow control and durability are required. Overall, the global market for sludge valves is characterized by a wide range of products, each designed to meet the specific needs of different industries and applications. As the demand for efficient and reliable sludge management solutions continues to grow, the market for sludge valves is expected to expand, driven by technological advancements and the increasing focus on sustainability and efficiency.

Municipal Facilities, Wastewater Treatment, Swimming Pool, Fish Pond, Others in the Sludge Valve - Global Market:

Sludge valves play a crucial role in various applications, including municipal facilities, wastewater treatment, swimming pools, fish ponds, and other areas where the management of sludge and debris is essential. In municipal facilities, sludge valves are used to control the flow of wastewater and other fluids, ensuring efficient and reliable operation of the system. These valves help prevent blockages and maintain optimal flow rates, reducing the risk of system failures and costly repairs. In wastewater treatment plants, sludge valves are critical components that help manage the flow of sludge and other materials throughout the treatment process. These valves ensure that the sludge is effectively separated and processed, allowing for the efficient removal of contaminants and the production of clean, safe water. In swimming pools, sludge valves are used to remove debris and maintain water quality, ensuring a safe and enjoyable environment for swimmers. These valves are typically easy to operate and maintain, providing reliable performance and minimal downtime. In fish ponds, sludge valves help manage the flow of water and debris, ensuring a healthy environment for aquatic life. These valves help prevent the buildup of harmful substances and maintain optimal water quality, promoting the health and well-being of the fish and other aquatic organisms. Other applications for sludge valves include industrial processes, mining operations, and chemical processing, where the management of sludge and other materials is critical for efficient and safe operation. In these industries, sludge valves help control the flow of abrasive and viscous materials, ensuring reliable performance and minimal maintenance requirements. Overall, sludge valves are essential components in a wide range of applications, providing reliable and efficient flow control for the management of sludge and other materials. As the demand for effective waste management solutions continues to grow, the market for sludge valves is expected to expand, driven by technological advancements and the increasing focus on sustainability and efficiency.

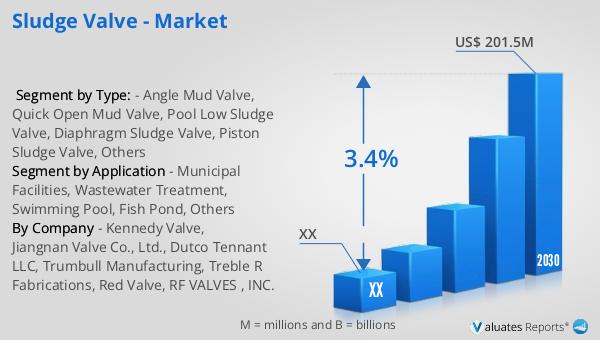

Sludge Valve - Global Market Outlook:

The global market for sludge valves was valued at approximately $158.7 million in 2023 and is projected to reach a revised size of $201.5 million by 2030, growing at a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. Emerson emerged as the leading company in the slurry valves industry, holding a market share of 12%, followed by other prominent players such as Weir Minerals, Metso, Orbinox, FLSmidth, DeZurik, Red Valve, Bray International, Stafsjo Valves, Flowrox, ITT Engineered Valves, CMO VALVE, Shanghai Hugong, Shanghai Huixuan, and Pskee Valves. North America represents the largest market for slurry valves, accounting for approximately 30% of the global market share, with China following closely behind with a market share of about 26%. This growth is driven by the increasing demand for efficient waste management solutions and the need for reliable equipment in industries such as wastewater treatment, mining, and chemical processing. As urbanization and industrial activities continue to expand, the demand for effective sludge management systems is expected to rise, further propelling the market for sludge valves. The market is characterized by a diverse range of products, including angle mud valves, quick open mud valves, pool low sludge valves, diaphragm sludge valves, and piston sludge valves, among others. Each type of valve offers unique features and benefits, catering to the specific needs of different applications and industries. As a result, the sludge valve market is poised for steady growth, driven by technological advancements and the increasing focus on sustainable and efficient waste management practices.

| Report Metric | Details |

| Report Name | Sludge Valve - Market |

| Forecasted market size in 2030 | US$ 201.5 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kennedy Valve, Jiangnan Valve Co., Ltd., Dutco Tennant LLC, Trumbull Manufacturing, Treble R Fabrications, Red Valve, RF VALVES , INC. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |