What is Pallet Flow Rack Storage Systems - Global Market?

Pallet Flow Rack Storage Systems are a specialized type of storage solution designed to optimize space and improve efficiency in warehouses and storage facilities. These systems use gravity to move pallets from the loading end to the picking end, allowing for a first-in, first-out (FIFO) inventory management system. This is particularly beneficial for businesses that deal with perishable goods or products with expiration dates, as it ensures that older stock is used before newer stock. The global market for these systems is expanding as more companies recognize the benefits of improved storage efficiency and reduced labor costs. With the ability to store multiple pallets deep, pallet flow rack systems maximize storage density and are ideal for high-volume operations. They are also customizable, allowing businesses to tailor the system to their specific needs, whether that involves accommodating different pallet sizes or integrating with automated systems. As industries continue to grow and evolve, the demand for efficient storage solutions like pallet flow rack systems is expected to rise, making them a crucial component of modern supply chain management.

Full-width Rollers, Magnum Rollers, Skate Wheel Rollers in the Pallet Flow Rack Storage Systems - Global Market:

In the realm of Pallet Flow Rack Storage Systems, different types of rollers play a pivotal role in ensuring the smooth and efficient movement of pallets. Full-width rollers are one of the most common types used in these systems. They span the entire width of the pallet, providing consistent support and stability as the pallet moves along the rack. This design minimizes the risk of pallets tipping or becoming misaligned, which can lead to jams or damage. Full-width rollers are particularly beneficial for handling heavy or unevenly loaded pallets, as they distribute the weight evenly across the roller surface. Magnum rollers, on the other hand, are designed for heavy-duty applications. They are typically larger and more robust than standard rollers, making them ideal for environments where pallets are frequently loaded with heavy goods. The increased diameter and strength of magnum rollers allow them to withstand greater loads and reduce wear and tear over time. This durability makes them a cost-effective choice for businesses that require a reliable and long-lasting solution for their storage needs. Skate wheel rollers offer a different approach to pallet movement. Instead of a continuous roller surface, skate wheel rollers consist of multiple small wheels arranged in rows. This design provides flexibility and can accommodate pallets of varying sizes and shapes. Skate wheel rollers are often used in systems where lighter loads are common, as they offer less resistance and require less force to move the pallets. They are also advantageous in applications where quick and easy access to individual pallets is necessary, as the wheels allow for smooth and swift movement. Each type of roller has its own set of advantages and is suited to different operational needs. The choice between full-width rollers, magnum rollers, and skate wheel rollers depends on factors such as the weight and size of the pallets, the frequency of pallet movement, and the specific requirements of the storage facility. By selecting the appropriate roller type, businesses can enhance the efficiency and reliability of their pallet flow rack systems, ultimately improving their overall storage operations.

Distribution Centers, Manufacturing Facilities, E-Commerce & Retail, Others in the Pallet Flow Rack Storage Systems - Global Market:

Pallet Flow Rack Storage Systems are utilized across various sectors, each benefiting from the system's ability to enhance storage efficiency and streamline operations. In distribution centers, these systems are invaluable for managing large volumes of goods that need to be moved quickly and efficiently. The FIFO inventory management facilitated by pallet flow racks ensures that products are rotated properly, reducing waste and optimizing stock levels. This is particularly important in distribution centers that handle perishable goods or products with a limited shelf life. By maintaining an organized and efficient storage system, distribution centers can improve their throughput and reduce the time and labor required for order fulfillment. Manufacturing facilities also benefit significantly from pallet flow rack systems. In these environments, the ability to store raw materials and finished products efficiently is crucial to maintaining smooth production processes. Pallet flow racks allow for easy access to materials, reducing downtime and ensuring that production lines remain stocked and operational. The high-density storage capability of these systems also helps manufacturers maximize their available space, allowing them to store more materials without expanding their physical footprint. In the e-commerce and retail sectors, pallet flow rack systems play a critical role in managing inventory and fulfilling orders. With the rapid growth of online shopping, retailers need efficient storage solutions to keep up with demand and ensure timely delivery of products. Pallet flow racks provide the necessary organization and accessibility to manage a wide range of products, from small items to bulk goods. The ability to quickly and easily access inventory helps retailers maintain accurate stock levels and reduce the risk of stockouts or overstocking. Other industries, such as food and beverage, pharmaceuticals, and automotive, also utilize pallet flow rack systems to improve their storage operations. In the food and beverage industry, for example, the FIFO system is essential for managing products with expiration dates, ensuring that older stock is used first. In the pharmaceutical industry, pallet flow racks help maintain the integrity of sensitive products by providing a controlled and organized storage environment. The automotive industry benefits from the system's ability to store large and heavy components efficiently, reducing the need for additional storage space. Overall, the versatility and efficiency of pallet flow rack storage systems make them a valuable asset across a wide range of industries, helping businesses optimize their storage operations and improve their overall supply chain management.

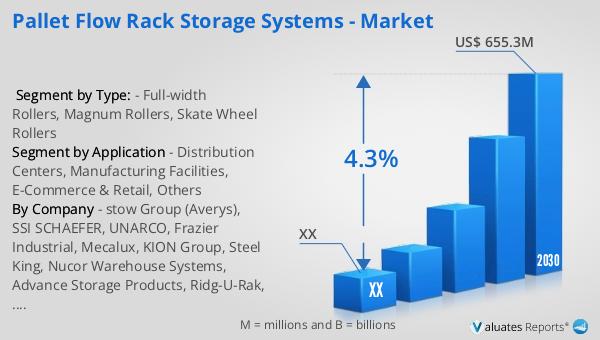

Pallet Flow Rack Storage Systems - Global Market Outlook:

The global market for Pallet Flow Rack Storage Systems was valued at approximately $494 million in 2023. This market is projected to grow steadily, reaching an estimated size of $655.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.3% over the forecast period from 2024 to 2030. The increasing demand for efficient storage solutions across various industries is a key driver of this market expansion. As businesses continue to seek ways to optimize their storage operations and improve supply chain efficiency, the adoption of pallet flow rack systems is expected to rise. These systems offer numerous benefits, including improved space utilization, reduced labor costs, and enhanced inventory management, making them an attractive option for companies looking to streamline their operations. Additionally, advancements in technology and the development of more durable and versatile pallet flow rack systems are likely to further fuel market growth. As the market continues to evolve, companies that invest in these systems can expect to see significant improvements in their storage efficiency and overall operational performance.

| Report Metric | Details |

| Report Name | Pallet Flow Rack Storage Systems - Market |

| Forecasted market size in 2030 | US$ 655.3 million |

| CAGR | 4.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | stow Group (Averys), SSI SCHAEFER, UNARCO, Frazier Industrial, Mecalux, KION Group, Steel King, Nucor Warehouse Systems, Advance Storage Products, Ridg-U-Rak, Nedcon, AR Racking, Konstant, Speedrack, Dexion (Gonvarri Material Handling), Rack Builders, Nanjing Inform, Mallard Manufacturing, JINGXING, Craftsman Automation Limited, Nanjing Kingmore, Nanjing Eurasia, North American Steel, Jiangsu NOVA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |