What is Global Stationary Hydrogen Analyzer Market?

The Global Stationary Hydrogen Analyzer Market refers to the industry focused on the production and distribution of devices that measure hydrogen concentration in various environments. These analyzers are crucial for monitoring hydrogen levels in industrial settings to ensure safety and efficiency. Hydrogen analyzers are used in a range of applications, including metallurgy, power generation, petrochemical processing, and fertilizer production. They help detect hydrogen leaks, prevent explosions, and optimize processes by providing accurate and real-time data on hydrogen concentrations. The market for these devices is expanding due to the increasing demand for hydrogen as a clean energy source and the need for stringent safety measures in industries handling hydrogen. Technological advancements have led to the development of more sophisticated and reliable analyzers, further driving market growth. As industries continue to prioritize safety and efficiency, the demand for stationary hydrogen analyzers is expected to rise, making it a vital component of industrial safety and process optimization.

Below or Equal 2%(F.S), 2%-3%(F.S), Above 3%(F.S) in the Global Stationary Hydrogen Analyzer Market:

In the Global Stationary Hydrogen Analyzer Market, the accuracy and precision of hydrogen measurement are categorized based on the full-scale (F.S) percentage error. This categorization helps industries choose the right analyzer based on their specific needs and the level of precision required. The first category, Below or Equal 2% (F.S), represents analyzers with the highest precision. These devices are essential in industries where even the slightest deviation in hydrogen concentration can lead to significant safety risks or process inefficiencies. For instance, in the petrochemical industry, precise hydrogen measurement is crucial to prevent hazardous situations and ensure optimal chemical reactions. Analyzers in this category are often used in critical applications where safety and accuracy are paramount. The second category, 2%-3% (F.S), includes analyzers that offer a moderate level of precision. These devices are suitable for applications where slight variations in hydrogen concentration are acceptable and do not pose significant risks. Industries such as power generation and metallurgy often use analyzers in this category, where the focus is on maintaining efficiency and safety without the need for ultra-precise measurements. The third category, Above 3% (F.S), consists of analyzers with the least precision. These are typically used in applications where hydrogen concentration is less critical, and minor deviations do not impact safety or process outcomes significantly. Such analyzers are often employed in less sensitive areas of industrial operations or in preliminary stages of process monitoring. The choice of analyzer depends on various factors, including the specific industry requirements, the criticality of hydrogen measurement, and budget constraints. As the demand for hydrogen as a clean energy source grows, the need for accurate and reliable hydrogen analyzers across all precision categories is expected to increase. This growth is driven by the need to ensure safety, optimize processes, and comply with regulatory standards in industries handling hydrogen.

Metallurgy, Power, Petrochemical, Fertilizer, Others in the Global Stationary Hydrogen Analyzer Market:

The Global Stationary Hydrogen Analyzer Market finds extensive usage across various industries, each with unique requirements and applications. In the metallurgy industry, hydrogen analyzers are crucial for monitoring hydrogen levels during metal processing and treatment. Hydrogen can cause embrittlement in metals, leading to structural weaknesses and failures. By accurately measuring hydrogen concentrations, these analyzers help prevent such issues, ensuring the production of high-quality metal products. In the power generation sector, hydrogen analyzers play a vital role in maintaining the efficiency and safety of power plants. Hydrogen is often used as a cooling agent in generators, and any leakage can lead to explosive hazards. Stationary hydrogen analyzers provide real-time monitoring of hydrogen levels, enabling quick detection and response to potential leaks, thus ensuring the safe and efficient operation of power plants. The petrochemical industry relies heavily on hydrogen analyzers to optimize chemical processes and ensure safety. Hydrogen is a key component in various chemical reactions, and precise measurement is essential to maintain reaction efficiency and prevent hazardous situations. Analyzers help in monitoring hydrogen levels in reactors and pipelines, providing critical data for process control and safety management. In the fertilizer industry, hydrogen analyzers are used to monitor hydrogen levels during the production of ammonia, a key ingredient in fertilizers. Accurate hydrogen measurement is crucial to ensure the efficiency of the Haber-Bosch process, which synthesizes ammonia from nitrogen and hydrogen. By providing precise data on hydrogen concentrations, these analyzers help optimize production processes and improve product quality. Beyond these industries, hydrogen analyzers are also used in various other applications, such as research and development, environmental monitoring, and quality control. As the demand for hydrogen as a clean energy source continues to grow, the usage of stationary hydrogen analyzers is expected to expand across different sectors, driven by the need for safety, efficiency, and regulatory compliance.

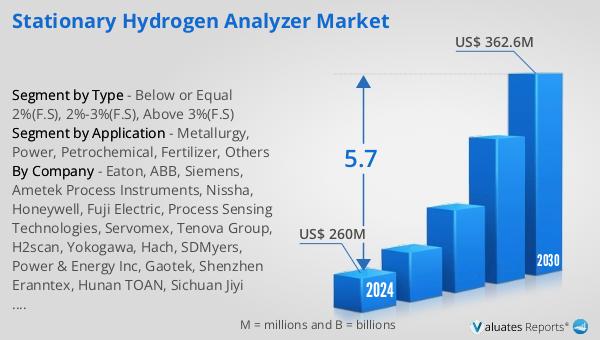

Global Stationary Hydrogen Analyzer Market Outlook:

The outlook for the Global Stationary Hydrogen Analyzer Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 260 million in 2024 to approximately US$ 362.6 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 5.7% over the forecast period. This upward trend is driven by several factors, including the increasing adoption of hydrogen as a clean energy source and the growing emphasis on industrial safety and efficiency. As industries worldwide continue to prioritize sustainable practices and safety measures, the demand for reliable hydrogen analyzers is set to rise. These devices play a crucial role in monitoring hydrogen levels, preventing potential hazards, and optimizing industrial processes. The market's growth is also supported by technological advancements that have led to the development of more sophisticated and accurate analyzers. As a result, industries are increasingly investing in these devices to enhance safety, improve operational efficiency, and comply with stringent regulatory standards. The expanding applications of hydrogen analyzers across various sectors, including metallurgy, power generation, petrochemical, and fertilizer industries, further contribute to the market's positive outlook. As the global focus on clean energy and safety intensifies, the Global Stationary Hydrogen Analyzer Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Stationary Hydrogen Analyzer Market |

| Accounted market size in 2024 | US$ 260 million |

| Forecasted market size in 2030 | US$ 362.6 million |

| CAGR | 5.7 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Eaton, ABB, Siemens, Ametek Process Instruments, Nissha, Honeywell, Fuji Electric, Process Sensing Technologies, Servomex, Tenova Group, H2scan, Yokogawa, Hach, SDMyers, Power & Energy Inc, Gaotek, Shenzhen Eranntex, Hunan TOAN, Sichuan Jiyi Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |