What is Global Medical Tube Cutting Machine Market?

The Global Medical Tube Cutting Machine Market is a specialized segment within the broader medical device industry, focusing on machines designed to cut medical tubes with precision and efficiency. These machines are essential in the production of various medical devices, as they ensure that tubes used in medical applications are cut to exact specifications, which is crucial for maintaining the integrity and functionality of medical equipment. The market for these machines is driven by the increasing demand for medical devices, advancements in medical technology, and the need for high-quality, reliable medical components. Medical tube cutting machines are used in the production of a wide range of medical devices, including catheters, IV tubes, and other tubing used in medical procedures. The market is characterized by a variety of machine types, each designed to handle different materials and cutting requirements, ensuring that manufacturers can meet the diverse needs of the medical industry. As the healthcare sector continues to grow and evolve, the demand for precise and efficient medical tube cutting machines is expected to increase, making this market an important component of the global medical device industry.

Electric, Pneumatic in the Global Medical Tube Cutting Machine Market:

Electric and pneumatic systems are two primary types of technologies used in the Global Medical Tube Cutting Machine Market, each offering distinct advantages and applications. Electric tube cutting machines are powered by electric motors, which provide consistent and precise cutting capabilities. These machines are known for their accuracy and ability to handle a wide range of materials, making them suitable for cutting complex and delicate medical tubes. Electric machines are often equipped with advanced features such as programmable controls, allowing for customization and automation of the cutting process. This makes them ideal for high-volume production environments where precision and efficiency are paramount. Additionally, electric machines tend to have lower operational costs compared to pneumatic systems, as they do not require compressed air, which can be expensive to generate and maintain. On the other hand, pneumatic tube cutting machines use compressed air to power their cutting mechanisms. These machines are known for their speed and ability to handle heavy-duty cutting tasks. Pneumatic systems are often preferred in environments where rapid cutting is required, as they can operate at high speeds without compromising on the quality of the cut. They are also more robust and durable, making them suitable for cutting thicker or more rigid materials that might pose a challenge for electric machines. However, pneumatic machines can be more expensive to operate due to the need for a constant supply of compressed air, and they may require more maintenance to ensure optimal performance. Both electric and pneumatic tube cutting machines play crucial roles in the medical device manufacturing process, and the choice between the two often depends on the specific requirements of the production environment. For instance, manufacturers that prioritize precision and automation may opt for electric machines, while those that need to cut large volumes of tubes quickly might prefer pneumatic systems. Additionally, advancements in technology have led to the development of hybrid machines that combine the benefits of both electric and pneumatic systems, offering manufacturers greater flexibility and efficiency in their production processes. In conclusion, the Global Medical Tube Cutting Machine Market is characterized by a diverse range of technologies, each designed to meet the specific needs of medical device manufacturers. Electric and pneumatic systems offer distinct advantages, and the choice between the two often depends on factors such as material type, production volume, and cost considerations. As the demand for medical devices continues to grow, the market for these machines is expected to expand, driven by the need for precise, efficient, and reliable cutting solutions.

Silica Gel, Heat Shrink Tubing, PVC, TPE, Emulsion, Others in the Global Medical Tube Cutting Machine Market:

The Global Medical Tube Cutting Machine Market finds its applications in various areas, including Silica Gel, Heat Shrink Tubing, PVC, TPE, Emulsion, and others. Each of these materials presents unique challenges and requirements for cutting, making the role of specialized tube cutting machines crucial in ensuring high-quality and precise cuts. Silica Gel, for instance, is a material commonly used in medical applications for its moisture-absorbing properties. Cutting silica gel tubes requires machines that can handle the material's delicate nature without causing damage or compromising its structural integrity. Medical tube cutting machines designed for silica gel are equipped with features that ensure clean and precise cuts, maintaining the material's effectiveness in medical applications. Heat Shrink Tubing is another area where medical tube cutting machines are extensively used. This material is often used to insulate wires and provide a protective covering in medical devices. Cutting heat shrink tubing requires precision to ensure that the tubing fits perfectly over the components it is meant to protect. Medical tube cutting machines used for this purpose are designed to handle the material's unique properties, providing clean cuts that facilitate easy application and installation. PVC (Polyvinyl Chloride) is a widely used material in the medical industry, known for its durability and flexibility. Cutting PVC tubes requires machines that can handle the material's toughness while ensuring precise cuts that meet the stringent standards of the medical industry. Medical tube cutting machines designed for PVC are equipped with advanced features that allow for customization and automation of the cutting process, ensuring that manufacturers can produce high-quality PVC tubes efficiently and cost-effectively. TPE (Thermoplastic Elastomer) is another material commonly used in medical applications for its flexibility and resilience. Cutting TPE tubes requires machines that can handle the material's elasticity without causing deformation or damage. Medical tube cutting machines designed for TPE are equipped with specialized cutting mechanisms that ensure clean and precise cuts, maintaining the material's integrity and functionality in medical applications. Emulsion, a mixture of two or more liquids, is also used in medical applications, often as a coating or adhesive. Cutting tubes coated with emulsion requires machines that can handle the material's unique properties without causing damage or compromising its effectiveness. Medical tube cutting machines designed for emulsion-coated tubes are equipped with features that ensure clean and precise cuts, maintaining the material's effectiveness in medical applications. In addition to these materials, medical tube cutting machines are also used for cutting a variety of other materials used in medical applications. These machines are designed to handle the unique challenges and requirements of each material, ensuring that manufacturers can produce high-quality medical tubes that meet the stringent standards of the medical industry. As the demand for medical devices continues to grow, the need for specialized tube cutting machines that can handle a wide range of materials is expected to increase, driving the growth of the Global Medical Tube Cutting Machine Market.

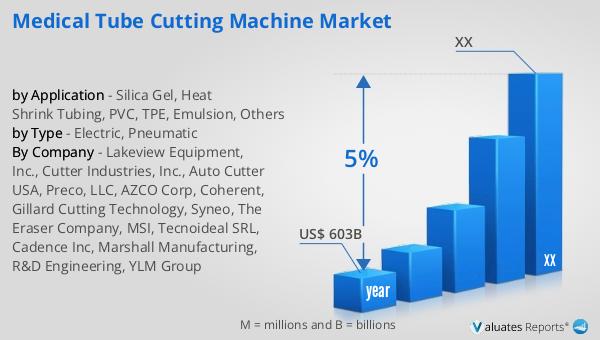

Global Medical Tube Cutting Machine Market Outlook:

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing demand for healthcare services. As medical technology continues to evolve, there is a growing need for innovative and efficient medical devices that can improve patient outcomes and streamline healthcare processes. This has led to increased investment in research and development, resulting in the introduction of new and advanced medical devices to the market. The aging global population is another significant factor contributing to the growth of the medical device market. As people live longer, there is a greater demand for medical devices that can help manage chronic conditions and improve quality of life. This has led to increased demand for devices such as pacemakers, insulin pumps, and other medical equipment that can help manage age-related health issues. Additionally, the increasing demand for healthcare services, particularly in emerging markets, is driving the growth of the medical device market. As more people gain access to healthcare services, there is a greater need for medical devices that can support diagnosis, treatment, and monitoring of various health conditions. This has led to increased demand for devices such as diagnostic imaging equipment, surgical instruments, and monitoring devices. Overall, the global medical device market is expected to continue its growth trajectory, driven by advancements in technology, an aging population, and increasing demand for healthcare services. As the market continues to expand, there will be a growing need for innovative and efficient medical devices that can meet the evolving needs of the healthcare industry.

| Report Metric | Details |

| Report Name | Medical Tube Cutting Machine Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Lakeview Equipment, Inc., Cutter Industries, Inc., Auto Cutter USA, Preco, LLC, AZCO Corp, Coherent, Gillard Cutting Technology, Syneo, The Eraser Company, MSI, Tecnoideal SRL, Cadence Inc, Marshall Manufacturing, R&D Engineering, YLM Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |