What is Global Industrial Autoclave Market?

The Global Industrial Autoclave Market refers to the worldwide industry focused on the production and sale of autoclaves, which are pressure chambers used to carry out industrial processes requiring elevated temperature and pressure different from ambient air pressure. These devices are essential in various sectors, including healthcare, aerospace, automotive, and manufacturing, for tasks such as sterilization, curing, and chemical reactions. The market is driven by the increasing demand for high-quality, durable products and the need for efficient and reliable sterilization processes. Technological advancements have led to the development of more sophisticated autoclaves that offer enhanced performance, energy efficiency, and user-friendly interfaces. Additionally, the growing emphasis on safety and regulatory compliance in industries like healthcare and food processing has further fueled the demand for industrial autoclaves. As industries continue to expand and innovate, the global industrial autoclave market is expected to grow, offering numerous opportunities for manufacturers and suppliers to cater to the diverse needs of their clients. The market's growth is also supported by the rising awareness of the benefits of using autoclaves, such as improved product quality, reduced operational costs, and enhanced safety measures.

Range 200 Liter or Less, Range 200 - 1000 Liter, Range 1000 Liter or More in the Global Industrial Autoclave Market:

In the Global Industrial Autoclave Market, autoclaves are categorized based on their capacity, which is typically measured in liters. The first category is the Range 200 Liter or Less, which includes smaller autoclaves often used in laboratories, small-scale manufacturing, and research facilities. These autoclaves are ideal for applications that require precise control over temperature and pressure but do not need large volumes. They are compact, making them suitable for environments with limited space, and are often used for sterilizing laboratory equipment, small batches of materials, and in educational settings for teaching purposes. The second category, Range 200 - 1000 Liter, encompasses medium-sized autoclaves that are versatile and widely used across various industries. These autoclaves are suitable for medium-scale production processes and are often found in industries such as pharmaceuticals, food processing, and chemical manufacturing. They offer a balance between capacity and efficiency, making them a popular choice for businesses that require reliable and consistent performance. The third category, Range 1000 Liter or More, includes large autoclaves designed for heavy-duty industrial applications. These autoclaves are used in sectors like aerospace, automotive, and large-scale manufacturing, where the processing of large components or high volumes of materials is necessary. They are built to handle significant workloads and are often customized to meet specific industry requirements. The large capacity of these autoclaves allows for the efficient processing of bulky items, such as aircraft parts, vehicle components, and large batches of materials. Each category of autoclave serves a unique purpose and is designed to meet the specific needs of different industries, ensuring that businesses can choose the right equipment for their operations. The diversity in autoclave sizes and capacities reflects the varied demands of the global market, highlighting the importance of flexibility and adaptability in industrial processes. As industries continue to evolve and expand, the demand for autoclaves across all capacity ranges is expected to grow, driven by the need for efficient, reliable, and high-quality processing solutions.

Automotive, Aerospace, Machinery, Other in the Global Industrial Autoclave Market:

The Global Industrial Autoclave Market finds extensive usage across various sectors, including automotive, aerospace, machinery, and others, each benefiting from the unique capabilities of autoclaves. In the automotive industry, autoclaves are primarily used for curing composite materials and components, ensuring they meet the stringent quality and safety standards required for vehicle production. The ability of autoclaves to provide uniform heat and pressure makes them ideal for producing high-performance parts, such as carbon fiber components, which are increasingly used in modern vehicles for their strength and lightweight properties. In the aerospace sector, autoclaves play a crucial role in the manufacturing of aircraft components, where precision and reliability are paramount. They are used to cure composite materials, ensuring the structural integrity and performance of critical parts like wings, fuselage sections, and engine components. The aerospace industry relies heavily on autoclaves to produce parts that can withstand extreme conditions and meet rigorous safety standards. In the machinery industry, autoclaves are used for various applications, including the sterilization of equipment and tools, as well as the curing of materials used in the production of machinery components. The ability to control temperature and pressure precisely makes autoclaves an essential tool for ensuring the quality and durability of machinery parts. Other industries, such as healthcare, food processing, and chemical manufacturing, also utilize autoclaves for sterilization and processing purposes. In healthcare, autoclaves are used to sterilize medical instruments and equipment, ensuring they are free from harmful microorganisms. In food processing, autoclaves are used to sterilize canned goods and other food products, extending their shelf life and ensuring safety for consumers. The chemical industry uses autoclaves for various reactions and processes that require controlled environments. Overall, the versatility and reliability of autoclaves make them indispensable in a wide range of industries, each benefiting from their ability to enhance product quality, safety, and efficiency.

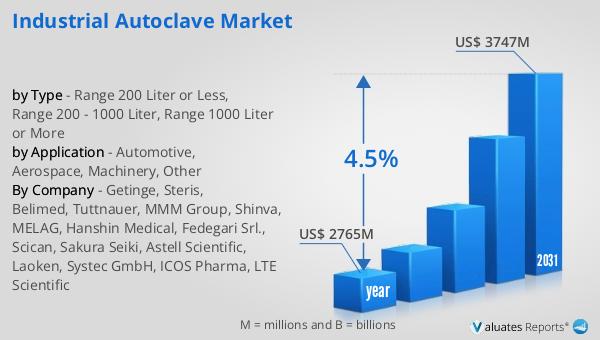

Global Industrial Autoclave Market Outlook:

The outlook for the Global Industrial Autoclave Market indicates a promising future, with the market valued at approximately $2,765 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $3,747 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.5% over the forecast period. The increasing demand for autoclaves across various industries, driven by the need for efficient and reliable processing solutions, is a key factor contributing to this growth. As industries continue to expand and innovate, the demand for high-quality, durable products is expected to rise, further fueling the market's expansion. Technological advancements in autoclave design and functionality are also expected to play a significant role in driving market growth, as businesses seek more efficient and user-friendly equipment. Additionally, the growing emphasis on safety and regulatory compliance in industries such as healthcare and food processing is likely to boost the demand for autoclaves, as they provide a reliable means of ensuring product safety and quality. Overall, the Global Industrial Autoclave Market is poised for steady growth, offering numerous opportunities for manufacturers and suppliers to cater to the diverse needs of their clients.

| Report Metric | Details |

| Report Name | Industrial Autoclave Market |

| Accounted market size in year | US$ 2765 million |

| Forecasted market size in 2031 | US$ 3747 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Getinge, Steris, Belimed, Tuttnauer, MMM Group, Shinva, MELAG, Hanshin Medical, Fedegari Srl., Scican, Sakura Seiki, Astell Scientific, Laoken, Systec GmbH, ICOS Pharma, LTE Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |