What is 3D Printing Aluminum Materials - Global Market?

3D printing aluminum materials represent a significant advancement in the field of additive manufacturing, offering a versatile and efficient way to produce complex metal parts. This global market is centered around the use of aluminum alloys in 3D printing processes, which are known for their lightweight properties, strength, and resistance to corrosion. These materials are particularly appealing in industries where weight reduction and durability are critical, such as aerospace, automotive, and defense. The process involves using a laser or electron beam to fuse aluminum powder layer by layer, creating intricate designs that would be challenging or impossible to achieve with traditional manufacturing methods. The global market for these materials is expanding as more industries recognize the benefits of 3D printing, including reduced material waste, faster production times, and the ability to customize parts for specific applications. As technology advances, the range of aluminum alloys available for 3D printing continues to grow, offering even more possibilities for innovation and efficiency in manufacturing. This market is poised for significant growth as industries increasingly adopt 3D printing technologies to meet their production needs.

AlSi10Mg, AlSi7Mg, AlSi12, Scalmalloy, Others in the 3D Printing Aluminum Materials - Global Market:

AlSi10Mg, AlSi7Mg, AlSi12, Scalmalloy, and other aluminum alloys are pivotal in the 3D printing aluminum materials market, each offering unique properties that cater to different industrial needs. AlSi10Mg is one of the most commonly used aluminum alloys in 3D printing due to its excellent mechanical properties and good thermal conductivity. It is particularly favored in the automotive and aerospace industries for producing lightweight yet strong components. The alloy's silicon content provides good casting properties, while magnesium enhances its strength and hardness, making it ideal for high-stress applications. AlSi7Mg, on the other hand, offers a slightly different composition with lower silicon content, which results in improved ductility and corrosion resistance. This makes it suitable for applications where flexibility and durability are essential, such as in the production of complex geometries and thin-walled structures. AlSi12 is another popular choice, known for its high silicon content, which provides excellent wear resistance and low thermal expansion. This alloy is often used in applications requiring high precision and stability under thermal stress, such as in the electronics and tooling industries. Scalmalloy, a high-performance aluminum alloy, is renowned for its exceptional strength-to-weight ratio and fatigue resistance. Developed specifically for additive manufacturing, Scalmalloy is used in demanding applications like aerospace and motorsports, where performance and reliability are paramount. Its unique composition, which includes scandium, enhances its mechanical properties, making it one of the strongest aluminum alloys available for 3D printing. Beyond these specific alloys, the market also includes other aluminum materials tailored for specialized applications, offering a wide range of options for manufacturers looking to leverage the benefits of 3D printing. These materials are continually being developed and refined to meet the evolving demands of various industries, ensuring that 3D printing remains at the forefront of manufacturing innovation.

Aerospace and Defense, Automotive, Academic Institutions, Others in the 3D Printing Aluminum Materials - Global Market:

The usage of 3D printing aluminum materials spans several key industries, each benefiting from the unique advantages that additive manufacturing offers. In the aerospace and defense sectors, the ability to produce lightweight yet strong components is crucial. 3D printing with aluminum allows for the creation of complex geometries that are not feasible with traditional manufacturing methods, leading to significant weight reductions in aircraft and spacecraft components. This not only improves fuel efficiency but also enhances performance and reduces emissions. Additionally, the defense industry benefits from the rapid prototyping capabilities of 3D printing, enabling the quick development and testing of new designs and technologies. In the automotive industry, 3D printing aluminum materials are used to produce parts that require high strength and low weight, such as engine components, brackets, and structural parts. The ability to customize and optimize designs for specific applications leads to improved vehicle performance and efficiency. Furthermore, the reduced lead times associated with 3D printing allow for faster production cycles and quicker time-to-market for new models. Academic institutions are also leveraging 3D printing aluminum materials for research and development purposes. The technology provides a valuable tool for exploring new design concepts and testing innovative ideas in a cost-effective and efficient manner. Students and researchers can experiment with complex geometries and material properties, gaining hands-on experience with cutting-edge manufacturing techniques. Beyond these specific areas, 3D printing aluminum materials are finding applications in a variety of other industries, including electronics, healthcare, and consumer goods. The versatility and adaptability of 3D printing make it an attractive option for producing customized products and components, meeting the diverse needs of different markets. As the technology continues to evolve, the range of applications for 3D printing aluminum materials is expected to expand, driving further innovation and growth across multiple sectors.

3D Printing Aluminum Materials - Global Market Outlook:

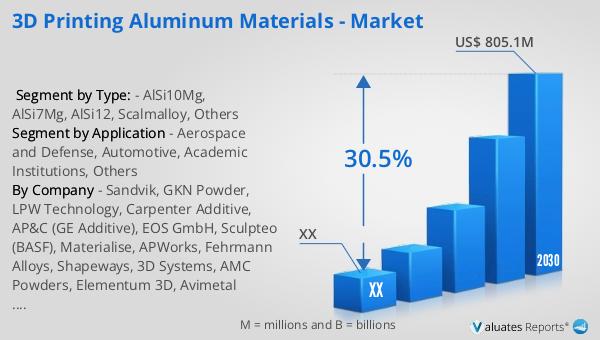

The global market for 3D printing aluminum materials was valued at approximately $135 million in 2023, with projections indicating a substantial increase to around $805.1 million by 2030. This growth represents a compound annual growth rate (CAGR) of 30.5% over the forecast period from 2024 to 2030. The increasing adoption of 3D printing technologies across various industries is a key driver of this market expansion. Aluminum materials are gaining significant attention in the additive manufacturing industry due to their unique properties, such as lightweight, strength, and corrosion resistance. These attributes make them ideal for producing complex and high-performance components in sectors like aerospace, automotive, and defense. The ability to create intricate designs with reduced material waste and faster production times is also contributing to the growing demand for 3D printing aluminum materials. As more industries recognize the benefits of this technology, the market is expected to continue its upward trajectory, offering new opportunities for innovation and efficiency in manufacturing. The ongoing development of new aluminum alloys and advancements in 3D printing technology are further enhancing the capabilities and applications of these materials, solidifying their position as a vital component of the additive manufacturing landscape.

| Report Metric | Details |

| Report Name | 3D Printing Aluminum Materials - Market |

| Forecasted market size in 2030 | US$ 805.1 million |

| CAGR | 30.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sandvik, GKN Powder, LPW Technology, Carpenter Additive, AP&C (GE Additive), EOS GmbH, Sculpteo (BASF), Materialise, APWorks, Fehrmann Alloys, Shapeways, 3D Systems, AMC Powders, Elementum 3D, Avimetal Powder Metallurgy Technology, Henan Yuanyang Powder Technology, ACME (Advanced Corporation for Materials & Equipments), Dongguan Hyper Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |