What is Ultrafine Pure Iron Powder - Global Market?

Ultrafine pure iron powder is a specialized material that plays a significant role in various industries due to its unique properties. This powder is characterized by its extremely small particle size, which enhances its reactivity and surface area, making it highly desirable for applications requiring precision and efficiency. The global market for ultrafine pure iron powder is driven by its demand in sectors such as automotive, metallurgy, home appliances, and the chemical industry. The powder's purity levels, ranging from 99% to 99.999%, determine its suitability for different applications, with higher purity levels often required for more specialized uses. The market is expanding as industries continue to innovate and seek materials that offer superior performance and sustainability. As a result, ultrafine pure iron powder is becoming increasingly integral to manufacturing processes, contributing to advancements in technology and product development. The global market's growth is supported by ongoing research and development efforts aimed at enhancing the powder's properties and discovering new applications, ensuring its continued relevance and importance in the industrial landscape.

2N(99%), 3N(99.9%), 4N(99.99%), 5N(99.999%) in the Ultrafine Pure Iron Powder - Global Market:

Ultrafine pure iron powder is available in various purity levels, each denoted by a specific "N" value, which indicates the number of nines in the percentage of purity. The 2N (99%) purity level is the most basic form, suitable for general applications where ultra-high purity is not critical. This level is often used in industries where cost-effectiveness is a priority, and the presence of minor impurities does not significantly affect the end product's performance. Moving up the purity scale, 3N (99.9%) ultrafine pure iron powder is used in applications requiring a higher degree of purity, such as certain chemical processes and metallurgical applications. The 3N level offers a balance between cost and performance, making it a popular choice for many industrial uses. The 4N (99.99%) purity level is where the powder begins to be used in more specialized applications, such as electronics and high-precision manufacturing. At this level, the powder's purity ensures minimal interference from impurities, which is crucial for processes that demand exacting standards. The 5N (99.999%) ultrafine pure iron powder represents the pinnacle of purity, used in the most demanding applications where even the slightest impurity can lead to significant issues. This level of purity is essential in advanced technologies, including certain types of semiconductors and high-tech equipment manufacturing. The global market for these varying purity levels of ultrafine pure iron powder is shaped by the specific needs of different industries, with each level offering distinct advantages and applications. As technology advances and industries push the boundaries of what is possible, the demand for higher purity levels is expected to grow, driving innovation and development in the production of ultrafine pure iron powder. The market's ability to supply these varying purity levels ensures that industries can select the most appropriate material for their specific needs, optimizing performance and efficiency across a wide range of applications.

Car, Metallurgy, Home Appliances, Chemical Industry, Others in the Ultrafine Pure Iron Powder - Global Market:

Ultrafine pure iron powder finds extensive use across several key industries, each leveraging its unique properties to enhance product performance and manufacturing efficiency. In the automotive industry, this powder is used in the production of various components, including brake pads and clutch plates, where its high surface area and reactivity contribute to improved friction and wear resistance. The powder's ability to be compacted and sintered into complex shapes also makes it ideal for producing lightweight, high-strength parts, which are crucial for modern vehicles focused on fuel efficiency and performance. In metallurgy, ultrafine pure iron powder is used as a raw material for producing high-quality steel and other alloys. Its purity and fine particle size allow for precise control over the composition and properties of the final product, leading to improved strength, durability, and corrosion resistance. This makes it an essential component in the production of advanced materials used in construction, aerospace, and other demanding applications. The home appliance industry also benefits from the use of ultrafine pure iron powder, particularly in the manufacturing of components such as motors and transformers. The powder's magnetic properties and high purity levels contribute to the efficiency and reliability of these devices, ensuring they operate smoothly and with minimal energy loss. In the chemical industry, ultrafine pure iron powder is used as a catalyst in various reactions, taking advantage of its high surface area and reactivity to accelerate chemical processes and improve yields. This is particularly important in the production of pharmaceuticals, where precise control over reaction conditions is essential for ensuring product quality and safety. Beyond these specific industries, ultrafine pure iron powder is also used in a variety of other applications, including the production of magnetic materials, electronics, and even certain types of batteries. Its versatility and unique properties make it a valuable material for a wide range of uses, driving demand across multiple sectors and contributing to the growth of the global market.

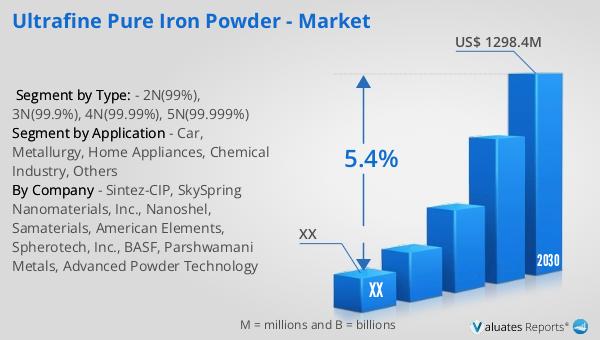

Ultrafine Pure Iron Powder - Global Market Outlook:

The global market for ultrafine pure iron powder was valued at approximately $892 million in 2023, with projections indicating a growth to around $1,298.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.4% over the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for ultrafine pure iron powder across various industries, driven by its unique properties and the ongoing push for technological advancements. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The anticipated expansion in this market is likely due to the strong presence of industries such as automotive, electronics, and metallurgy, which are major consumers of ultrafine pure iron powder. As these industries continue to innovate and seek materials that offer enhanced performance and sustainability, the demand for ultrafine pure iron powder is expected to rise. This growth is further supported by ongoing research and development efforts aimed at improving the powder's properties and discovering new applications, ensuring its continued relevance and importance in the industrial landscape. The market's ability to adapt to changing industry needs and technological advancements will be crucial in maintaining its growth trajectory and meeting the demands of a rapidly evolving global economy.

| Report Metric | Details |

| Report Name | Ultrafine Pure Iron Powder - Market |

| Forecasted market size in 2030 | US$ 1298.4 million |

| CAGR | 5.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sintez-CIP, SkySpring Nanomaterials, Inc., Nanoshel, Samaterials, American Elements, Spherotech, Inc., BASF, Parshwamani Metals, Advanced Powder Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |