What is Scrap Handling Magnets - Global Market?

Scrap handling magnets are specialized tools used in various industries to efficiently manage and transport scrap metal. These magnets are designed to lift and move ferrous materials, which are metals that contain iron, making them magnetic. The global market for scrap handling magnets is driven by the increasing demand for efficient scrap management solutions in industries such as recycling, construction, and manufacturing. These magnets come in different shapes and sizes, tailored to specific applications and operational needs. They are essential in reducing manual labor, enhancing safety, and improving the speed of operations. The market is characterized by technological advancements that have led to the development of more powerful and energy-efficient magnets. As industries continue to prioritize sustainability and cost-effectiveness, the demand for scrap handling magnets is expected to grow. This growth is further supported by the rising awareness of the benefits of recycling and the need for efficient waste management solutions. The global market for scrap handling magnets is a dynamic and evolving sector, with manufacturers continuously innovating to meet the changing needs of their customers.

Rectangular Magnets, Circular Magnets in the Scrap Handling Magnets - Global Market:

Rectangular and circular magnets are two primary types of scrap handling magnets used in the global market, each with distinct features and applications. Rectangular magnets are typically used in situations where a larger surface area is required for lifting and transporting scrap materials. Their shape allows them to cover more ground, making them ideal for handling large volumes of scrap metal in a single lift. This makes them particularly useful in industries where efficiency and speed are crucial, such as in large-scale recycling operations or in the construction industry where large metal beams and sheets need to be moved quickly. Rectangular magnets are often equipped with advanced features such as variable power settings and remote control capabilities, allowing operators to adjust the magnet's strength based on the weight and type of material being handled. This flexibility makes them a versatile tool in various industrial applications. On the other hand, circular magnets are designed for precision and are often used in applications where specific pieces of scrap metal need to be targeted and lifted. Their circular shape allows for a more focused magnetic field, which can be advantageous in situations where space is limited or where the scrap materials are densely packed. Circular magnets are commonly used in foundries and metal fabrication shops where precision is key. They are also favored in situations where the scrap materials are smaller or more delicate, as the focused magnetic field can help prevent damage to the materials. Both rectangular and circular magnets are integral to the scrap handling process, and the choice between the two often depends on the specific needs of the operation. Manufacturers in the global market continue to innovate and improve these magnets, incorporating new technologies such as smart sensors and automation to enhance their performance and efficiency. As industries continue to evolve and the demand for efficient scrap handling solutions grows, both rectangular and circular magnets are expected to play a crucial role in meeting these needs.

Foundry Industries, Recycling Industries, Others in the Scrap Handling Magnets - Global Market:

Scrap handling magnets are widely used in various industries, including foundry and recycling, due to their efficiency and effectiveness in managing scrap materials. In foundry industries, scrap handling magnets are essential for moving and sorting metal scraps, which are often recycled and reused in the production process. These magnets help streamline operations by reducing the need for manual labor and minimizing the risk of injury. They also enhance productivity by allowing for the quick and efficient movement of materials, which is crucial in a fast-paced foundry environment. In recycling industries, scrap handling magnets play a vital role in the sorting and processing of ferrous materials. They are used to separate magnetic metals from non-magnetic ones, ensuring that the recycling process is efficient and effective. This separation is crucial for maintaining the quality of recycled materials and for ensuring that non-ferrous materials are not contaminated with ferrous metals. Scrap handling magnets are also used in other industries, such as construction and manufacturing, where they help manage waste materials and improve operational efficiency. In these industries, magnets are used to lift and transport metal scraps, reducing the need for manual handling and improving safety. The use of scrap handling magnets in these industries is driven by the need for efficient and cost-effective solutions for managing scrap materials. As industries continue to prioritize sustainability and efficiency, the demand for scrap handling magnets is expected to grow. This growth is supported by the increasing awareness of the benefits of recycling and the need for effective waste management solutions. Overall, scrap handling magnets are a crucial tool in various industries, helping to improve efficiency, safety, and sustainability.

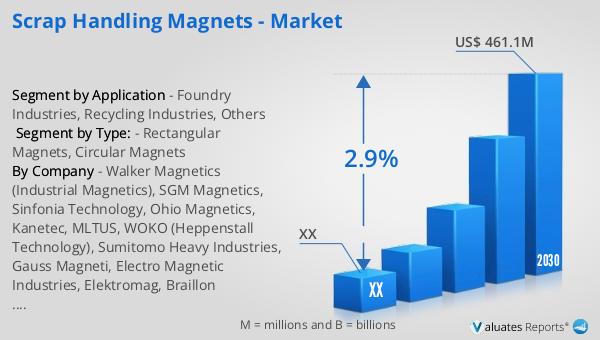

Scrap Handling Magnets - Global Market Outlook:

The global market for scrap handling magnets was valued at approximately $373 million in 2023 and is projected to reach an adjusted size of $461.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.9% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient scrap management solutions across various industries. In North America, the market for scrap handling magnets was valued at a significant amount in 2023 and is expected to grow steadily through 2030. The growth in this region is driven by the robust industrial sector and the increasing emphasis on recycling and sustainable practices. The market dynamics are influenced by technological advancements, which have led to the development of more powerful and energy-efficient magnets. These innovations are crucial in meeting the evolving needs of industries that rely on scrap handling magnets for efficient operations. As industries continue to prioritize cost-effectiveness and sustainability, the demand for scrap handling magnets is expected to rise, further driving market growth. The global market for scrap handling magnets is a dynamic and evolving sector, with manufacturers continuously innovating to meet the changing needs of their customers.

| Report Metric | Details |

| Report Name | Scrap Handling Magnets - Market |

| Forecasted market size in 2030 | US$ 461.1 million |

| CAGR | 2.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Walker Magnetics (Industrial Magnetics), SGM Magnetics, Sinfonia Technology, Ohio Magnetics, Kanetec, MLTUS, WOKO (Heppenstall Technology), Sumitomo Heavy Industries, Gauss Magneti, Electro Magnetic Industries, Elektromag, Braillon Magnetics, Walmag Magnetics, LONGi Magnet, Adoba GmbH, Papko Magnet Co., Gensco Equipment, Zanetti Magneti, Evertz Group, YATE Magnetics, Hunan Kemeida Electric, Wrinkle Industries (GRYB), Sarda Magnets, Kakku E & P Control Co., Moley Magnetics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |