What is PVC Paste Resin by Hybrid Method - Global Market?

PVC Paste Resin by Hybrid Method is a specialized material used in various industries due to its unique properties and versatility. This resin is produced through a hybrid method that combines different polymerization techniques to achieve a product with enhanced characteristics. The global market for PVC Paste Resin by Hybrid Method is growing steadily, driven by its increasing applications in sectors such as construction, automotive, and consumer goods. The resin is known for its excellent flexibility, durability, and resistance to chemicals, making it ideal for producing items like artificial leather, wallpapers, and other consumer products. The hybrid method of production allows manufacturers to tailor the resin's properties to meet specific requirements, enhancing its appeal in the market. As industries continue to seek materials that offer both performance and cost-effectiveness, the demand for PVC Paste Resin by Hybrid Method is expected to rise, contributing to its expanding market presence globally. This growth is further supported by advancements in production technologies and the increasing focus on sustainable and efficient manufacturing processes.

Calcium Carbide, VCM, EDC in the PVC Paste Resin by Hybrid Method - Global Market:

Calcium Carbide, VCM (Vinyl Chloride Monomer), and EDC (Ethylene Dichloride) are critical components in the production of PVC Paste Resin by Hybrid Method. Calcium Carbide is primarily used in the production of acetylene gas, which is a key raw material in the synthesis of VCM. The process begins with the reaction of calcium carbide with water to produce acetylene, which is then used to synthesize VCM through a series of chemical reactions. VCM is the primary building block for PVC, and its polymerization results in the formation of PVC resin. The hybrid method of producing PVC Paste Resin involves the combination of suspension and emulsion polymerization techniques, allowing for greater control over the resin's properties. EDC, on the other hand, is a precursor to VCM and is produced through the chlorination of ethylene. The production of EDC involves the reaction of ethylene with chlorine, resulting in the formation of EDC, which is then converted to VCM through thermal cracking. The integration of these processes in the hybrid method allows for the efficient production of PVC Paste Resin with enhanced properties. The use of calcium carbide, VCM, and EDC in the production of PVC Paste Resin by Hybrid Method highlights the complexity and sophistication of the chemical processes involved. These components play a crucial role in determining the quality and performance of the final product, making them indispensable in the global market for PVC Paste Resin. The demand for these raw materials is closely linked to the growth of the PVC Paste Resin market, as they are essential for the production of high-quality resin. As the market for PVC Paste Resin by Hybrid Method continues to expand, the demand for calcium carbide, VCM, and EDC is expected to increase, driving further advancements in production technologies and processes. The global market for these raw materials is characterized by a high degree of competition, with numerous players vying for market share. This competition is driven by the need to secure a stable supply of raw materials to meet the growing demand for PVC Paste Resin. The production of calcium carbide, VCM, and EDC is also subject to stringent environmental regulations, which necessitate the adoption of sustainable and environmentally friendly production practices. As a result, manufacturers are increasingly investing in research and development to improve the efficiency and sustainability of their production processes. The integration of advanced technologies and innovative production methods is expected to enhance the competitiveness of the global market for calcium carbide, VCM, and EDC, supporting the growth of the PVC Paste Resin market. The interplay between these raw materials and the production of PVC Paste Resin by Hybrid Method underscores the importance of a well-coordinated supply chain and the need for continuous innovation in the industry.

Artificial Leather, Wallpaper, Others in the PVC Paste Resin by Hybrid Method - Global Market:

PVC Paste Resin by Hybrid Method finds extensive usage in various applications, including artificial leather, wallpaper, and other consumer products. In the artificial leather industry, PVC Paste Resin is valued for its ability to mimic the appearance and texture of genuine leather while offering superior durability and resistance to wear and tear. The resin's flexibility and ease of processing make it an ideal choice for producing high-quality artificial leather products used in furniture, automotive interiors, and fashion accessories. The hybrid method of production allows manufacturers to customize the resin's properties, ensuring that the final product meets the specific requirements of different applications. In the wallpaper industry, PVC Paste Resin is used to produce wallpapers with enhanced durability, water resistance, and aesthetic appeal. The resin's ability to adhere to various substrates and its compatibility with different printing techniques make it a popular choice for creating a wide range of wallpaper designs. The use of PVC Paste Resin in wallpaper production also contributes to the development of eco-friendly and sustainable products, as it allows for the incorporation of recycled materials and the reduction of waste. Beyond artificial leather and wallpaper, PVC Paste Resin by Hybrid Method is used in a variety of other applications, including flooring, automotive parts, and consumer goods. Its versatility and adaptability make it a valuable material for producing products that require a combination of strength, flexibility, and resistance to environmental factors. The global market for PVC Paste Resin by Hybrid Method is driven by the increasing demand for high-performance materials in these applications, as well as the growing focus on sustainability and environmental responsibility. As industries continue to seek innovative solutions to meet the evolving needs of consumers, the use of PVC Paste Resin by Hybrid Method is expected to expand, further solidifying its position in the global market. The ongoing advancements in production technologies and the development of new applications for PVC Paste Resin are likely to drive its growth in the coming years, offering new opportunities for manufacturers and consumers alike.

PVC Paste Resin by Hybrid Method - Global Market Outlook:

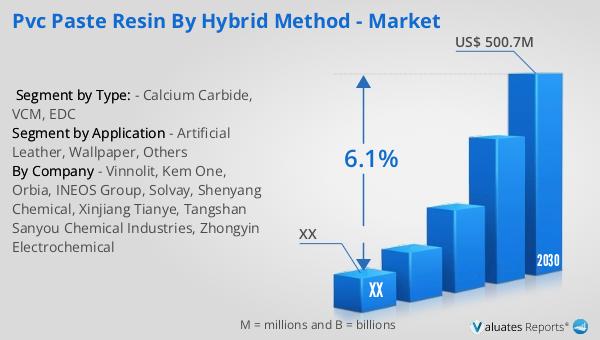

The global market for PVC Paste Resin by Hybrid Method was valued at approximately $329 million in 2023, with projections indicating a growth to around $500.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. The North American market, in particular, is expected to experience significant growth, although specific figures for this region were not provided. The increasing demand for PVC Paste Resin by Hybrid Method in various industries, such as construction, automotive, and consumer goods, is a key driver of this market expansion. The resin's unique properties, including its flexibility, durability, and resistance to chemicals, make it an attractive choice for manufacturers seeking high-performance materials. Additionally, advancements in production technologies and the growing focus on sustainable manufacturing processes are expected to further support the market's growth. As industries continue to evolve and adapt to changing consumer preferences and environmental regulations, the demand for PVC Paste Resin by Hybrid Method is likely to increase, contributing to its expanding market presence globally. The market outlook for PVC Paste Resin by Hybrid Method highlights the potential for continued growth and innovation in this sector, offering new opportunities for manufacturers and consumers alike.

| Report Metric | Details |

| Report Name | PVC Paste Resin by Hybrid Method - Market |

| Forecasted market size in 2030 | US$ 500.7 million |

| CAGR | 6.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Vinnolit, Kem One, Orbia, INEOS Group, Solvay, Shenyang Chemical, Xinjiang Tianye, Tangshan Sanyou Chemical Industries, Zhongyin Electrochemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |