What is PECVD Coating Machine - Global Market?

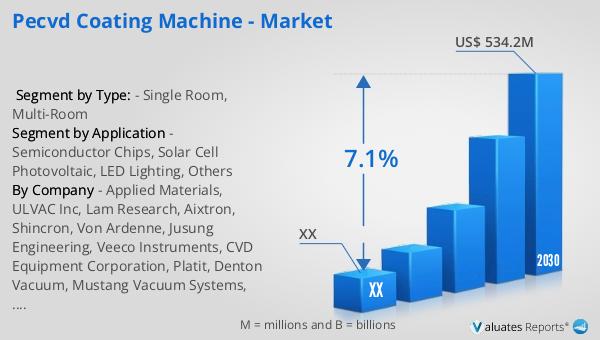

The PECVD (Plasma Enhanced Chemical Vapor Deposition) Coating Machine is a sophisticated piece of equipment used in various industries to deposit thin films on substrates. This technology utilizes plasma to enhance the chemical reaction rates of the vaporized materials, allowing for the deposition of coatings at lower temperatures compared to traditional methods. The global market for PECVD Coating Machines is driven by the increasing demand for advanced coatings in industries such as electronics, solar energy, and LED lighting. These machines are crucial for producing high-quality, uniform coatings that improve the performance and durability of products. As industries continue to innovate and seek more efficient production methods, the demand for PECVD Coating Machines is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on developing machines that offer higher precision, efficiency, and versatility. The global market for PECVD Coating Machines was valued at approximately US$ 329 million in 2023, with projections indicating a growth to US$ 534.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2024 to 2030.

Single Room, Multi-Room in the PECVD Coating Machine - Global Market:

In the realm of PECVD Coating Machines, the distinction between single-room and multi-room configurations plays a significant role in determining the machine's application and efficiency. Single-room PECVD machines are typically designed for smaller-scale operations or specialized applications where precision and control are paramount. These machines are often used in research and development settings or for the production of high-value, low-volume products. The single-room setup allows for meticulous control over the deposition process, ensuring uniformity and consistency in the coatings. This configuration is particularly beneficial for industries that require stringent quality standards, such as semiconductor manufacturing and advanced electronics. On the other hand, multi-room PECVD machines are engineered for large-scale production environments where high throughput and efficiency are critical. These machines are equipped with multiple chambers, allowing for simultaneous processing of multiple substrates. This configuration significantly enhances productivity, making it ideal for industries like solar cell manufacturing and large-scale LED production. The ability to process multiple substrates concurrently reduces downtime and increases the overall output, catering to the growing demand for coated products in various sectors. The choice between single-room and multi-room PECVD machines depends largely on the specific requirements of the industry and the scale of production. While single-room machines offer unparalleled precision and control, multi-room machines provide the advantage of high-volume production capabilities. As the global market for PECVD Coating Machines continues to expand, manufacturers are investing in research and development to enhance the capabilities of both single-room and multi-room configurations. Innovations in automation, process control, and material compatibility are driving the evolution of these machines, enabling them to meet the diverse needs of modern industries. The integration of advanced technologies such as artificial intelligence and machine learning is also being explored to optimize the performance and efficiency of PECVD Coating Machines. These advancements are expected to further propel the growth of the global market, as industries increasingly rely on PECVD technology to achieve superior coating quality and performance. The ongoing development of new materials and applications for PECVD coatings is also contributing to the market's expansion, as industries seek to leverage the unique properties of these coatings to enhance their products. As a result, the demand for both single-room and multi-room PECVD machines is anticipated to rise, driven by the need for high-quality, cost-effective coating solutions across various sectors.

Semiconductor Chips, Solar Cell Photovoltaic, LED Lighting, Others in the PECVD Coating Machine - Global Market:

The PECVD Coating Machine is a versatile tool with applications spanning several key industries, including semiconductor chips, solar cell photovoltaics, LED lighting, and others. In the semiconductor industry, PECVD machines are essential for depositing dielectric and conductive layers on chips. These coatings are crucial for the performance and reliability of semiconductor devices, as they provide insulation, protection, and enhanced electrical properties. The precision and control offered by PECVD technology make it ideal for the intricate and demanding requirements of semiconductor manufacturing. In the solar cell photovoltaic industry, PECVD machines are used to deposit anti-reflective coatings and passivation layers on solar cells. These coatings improve the efficiency of solar cells by reducing reflection and enhancing light absorption. The ability to deposit uniform and high-quality coatings is critical for maximizing the energy conversion efficiency of solar panels. As the demand for renewable energy sources continues to grow, the role of PECVD technology in solar cell production is becoming increasingly important. In the LED lighting industry, PECVD machines are employed to deposit coatings that enhance the performance and longevity of LED devices. These coatings can improve light output, thermal management, and environmental resistance, making LEDs more efficient and durable. The versatility of PECVD technology allows for the deposition of a wide range of materials, enabling manufacturers to tailor the properties of LED coatings to meet specific performance criteria. Beyond these industries, PECVD machines are also used in various other applications, such as optical coatings, protective coatings for medical devices, and barrier coatings for packaging materials. The ability to deposit thin films with precise control over thickness and composition makes PECVD technology suitable for a diverse array of applications. As industries continue to innovate and seek advanced coating solutions, the demand for PECVD Coating Machines is expected to grow. The global market for these machines is driven by the need for high-quality, reliable coatings that enhance the performance and durability of products across various sectors. The ongoing development of new materials and applications for PECVD coatings is also contributing to the market's expansion, as industries seek to leverage the unique properties of these coatings to enhance their products.

PECVD Coating Machine - Global Market Outlook:

The global market for PECVD Coating Machines was valued at approximately US$ 329 million in 2023, with projections indicating a growth to US$ 534.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced coatings in industries such as electronics, solar energy, and LED lighting. The North American market for PECVD Coating Machines is also expected to experience significant growth during this period, although specific figures for this region were not provided. The market's expansion is attributed to technological advancements and the growing need for high-quality, reliable coatings that enhance the performance and durability of products across various sectors. As industries continue to innovate and seek more efficient production methods, the demand for PECVD Coating Machines is expected to grow. Manufacturers are focusing on developing machines that offer higher precision, efficiency, and versatility to meet the diverse needs of modern industries. The integration of advanced technologies such as artificial intelligence and machine learning is also being explored to optimize the performance and efficiency of PECVD Coating Machines. These advancements are expected to further propel the growth of the global market, as industries increasingly rely on PECVD technology to achieve superior coating quality and performance.

| Report Metric | Details |

| Report Name | PECVD Coating Machine - Market |

| Forecasted market size in 2030 | US$ 534.2 million |

| CAGR | 7.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Applied Materials, ULVAC Inc, Lam Research, Aixtron, Shincron, Von Ardenne, Jusung Engineering, Veeco Instruments, CVD Equipment Corporation, Platit, Denton Vacuum, Mustang Vacuum Systems, Bühler Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |