What is Miniature Pneumatic Gripper - Global Market?

Miniature pneumatic grippers are small, yet powerful devices used in various industries to handle and manipulate objects with precision. These grippers use compressed air to operate, making them efficient and reliable for tasks that require delicate handling. The global market for miniature pneumatic grippers is expanding as industries seek more efficient automation solutions. These grippers are particularly valued for their ability to perform tasks in tight spaces where larger grippers cannot operate. They are commonly used in assembly lines, robotics, and other automated systems to pick, place, and hold objects securely. The demand for these grippers is driven by the need for increased productivity and precision in manufacturing processes. As industries continue to automate, the need for compact and efficient gripping solutions like miniature pneumatic grippers is expected to grow. Their versatility and efficiency make them an essential component in modern manufacturing and automation systems. The global market for these grippers is poised for growth as more industries recognize their potential to enhance productivity and reduce operational costs.

Parallel Grippers, Angular Grippers, Three-jaw Grippers, Other in the Miniature Pneumatic Gripper - Global Market:

Parallel grippers, angular grippers, and three-jaw grippers are different types of miniature pneumatic grippers, each designed for specific applications. Parallel grippers are the most common type, featuring two fingers that move in parallel to grip an object. They are ideal for handling objects with consistent shapes and sizes, providing a firm and stable grip. These grippers are widely used in industries where precision and repeatability are crucial, such as electronics and pharmaceuticals. Angular grippers, on the other hand, have fingers that open at an angle, making them suitable for applications where space is limited. They are often used in situations where the gripper needs to reach into tight spaces or handle objects with irregular shapes. Angular grippers are popular in the automotive and aerospace industries, where components often have complex geometries. Three-jaw grippers provide a more secure grip by using three fingers to hold an object. This type of gripper is ideal for handling cylindrical or round objects, offering a balanced and stable grip. They are commonly used in the machining and metalworking industries, where precision and stability are paramount. Other types of miniature pneumatic grippers include vacuum grippers and magnetic grippers, each designed for specific applications. Vacuum grippers use suction to hold objects, making them ideal for handling delicate or porous materials. Magnetic grippers, on the other hand, use magnetic force to hold ferrous objects securely. These grippers are often used in industries where speed and efficiency are critical, such as packaging and logistics. Each type of gripper has its unique advantages and is chosen based on the specific requirements of the application. The global market for miniature pneumatic grippers is diverse, with each type catering to different industrial needs. As industries continue to evolve, the demand for specialized grippers that can handle specific tasks efficiently is expected to increase. The versatility and adaptability of these grippers make them an essential tool in modern manufacturing and automation processes.

Aerospace, Automobile, Consumer Goods, Package, Other in the Miniature Pneumatic Gripper - Global Market:

Miniature pneumatic grippers are used in various industries, including aerospace, automobile, consumer goods, packaging, and others, due to their precision and efficiency. In the aerospace industry, these grippers are used to handle delicate components and materials with precision. They are essential in the assembly of aircraft parts, where accuracy and reliability are crucial. The ability of miniature pneumatic grippers to operate in tight spaces makes them ideal for aerospace applications, where space is often limited. In the automobile industry, these grippers are used in assembly lines to handle various components, from small parts to larger assemblies. Their ability to provide a firm and stable grip ensures that components are handled with care, reducing the risk of damage during the manufacturing process. In the consumer goods industry, miniature pneumatic grippers are used to handle a wide range of products, from electronics to household items. Their versatility allows them to adapt to different shapes and sizes, making them ideal for handling diverse products. In the packaging industry, these grippers are used to handle packages of various sizes and shapes, ensuring that products are securely held during the packaging process. Their efficiency and reliability make them an essential tool in high-speed packaging lines. Other industries that use miniature pneumatic grippers include electronics, pharmaceuticals, and food and beverage, where precision and efficiency are critical. The global market for these grippers is expanding as more industries recognize their potential to enhance productivity and reduce operational costs. Their versatility and adaptability make them an essential component in modern manufacturing and automation systems.

Miniature Pneumatic Gripper - Global Market Outlook:

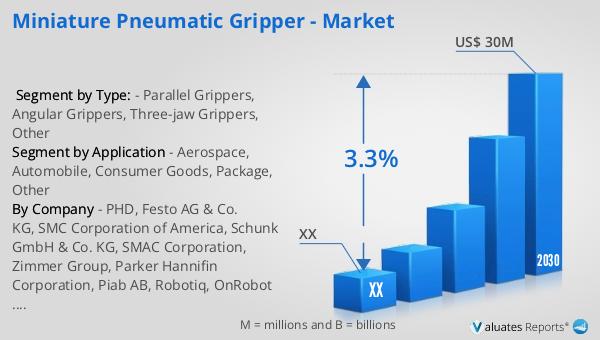

The global market for miniature pneumatic grippers was valued at approximately $24 million in 2023. This market is projected to grow, reaching an estimated value of $30 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This steady growth is indicative of the increasing demand for efficient and reliable automation solutions across various industries. As industries continue to automate their processes, the need for compact and efficient gripping solutions like miniature pneumatic grippers is expected to rise. These grippers offer a cost-effective solution for industries looking to enhance productivity and reduce operational costs. The versatility and adaptability of these grippers make them an essential tool in modern manufacturing and automation systems. As more industries recognize the potential of these grippers to improve efficiency and precision, the global market is poised for continued growth. The increasing adoption of automation technologies in various industries is expected to drive the demand for miniature pneumatic grippers, further contributing to the market's growth. The global market for these grippers is diverse, with each type catering to different industrial needs. As industries continue to evolve, the demand for specialized grippers that can handle specific tasks efficiently is expected to increase. The versatility and adaptability of these grippers make them an essential tool in modern manufacturing and automation processes.

| Report Metric | Details |

| Report Name | Miniature Pneumatic Gripper - Market |

| Forecasted market size in 2030 | US$ 30 million |

| CAGR | 3.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | PHD, Festo AG & Co. KG, SMC Corporation of America, Schunk GmbH & Co. KG, SMAC Corporation, Zimmer Group, Parker Hannifin Corporation, Piab AB, Robotiq, OnRobot A/S, Bimba Manufacturing Company, Clippard Instrument Laboratory, EMI Corp, FIPA GmbH, Gimatic S.r.l., Honeywell Internationa, JELPC Automation Equipment, Koganei Corporation, Aventics GmbH, Robohand |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |