What is Metal Cutting and Machine Tool - Global Market?

Metal cutting and machine tools are essential components in the manufacturing industry, playing a crucial role in shaping and forming metal parts for various applications. The global market for these tools encompasses a wide range of machinery and equipment designed to cut, shape, and finish metal workpieces. This market includes traditional tools like lathes, milling machines, and grinders, as well as advanced technologies such as computer numerical control (CNC) machines. These tools are used across numerous industries, including automotive, aerospace, construction, and electronics, to produce precision components and assemblies. The demand for metal cutting and machine tools is driven by the need for high-quality, efficient, and cost-effective manufacturing processes. As industries continue to evolve and adopt new technologies, the market for these tools is expected to grow, driven by advancements in automation, digitalization, and the increasing complexity of manufacturing requirements. The global market is characterized by a diverse range of products and services, catering to the specific needs of different industries and applications.

Laser Cutter, Water Jet Cutting Machine, Plasma Cutting Machine, Flame Cutting Machine in the Metal Cutting and Machine Tool - Global Market:

In the realm of metal cutting and machine tools, several advanced technologies have emerged, each offering unique capabilities and benefits. Laser cutters, for instance, utilize a focused beam of light to cut through metal with high precision and speed. This technology is particularly advantageous for intricate designs and thin materials, as it provides clean cuts with minimal thermal distortion. Laser cutting is widely used in industries such as automotive and electronics, where precision and efficiency are paramount. On the other hand, water jet cutting machines employ a high-pressure stream of water, often mixed with abrasive materials, to cut through metal. This method is highly versatile, capable of cutting a wide range of materials without generating heat, which makes it ideal for applications where thermal effects must be minimized. Water jet cutting is commonly used in aerospace and defense industries, where material integrity is critical. Plasma cutting machines, meanwhile, use an electrically conductive gas to transfer energy from a power supply to a conductive material, effectively cutting through thick metal sheets. This technology is known for its speed and ability to cut through a variety of metals, making it a popular choice in heavy industries such as shipbuilding and construction. Lastly, flame cutting machines, also known as oxy-fuel cutting, use a combination of oxygen and fuel gases to cut through metal. This traditional method is particularly effective for cutting thick steel plates and is widely used in industries like construction and shipbuilding. Each of these technologies offers distinct advantages and is chosen based on the specific requirements of the application, such as material type, thickness, and desired precision. As the global market for metal cutting and machine tools continues to evolve, these technologies are expected to play a significant role in meeting the diverse needs of various industries.

Car, Aerospace and Defense, Architecture and Construction, Electronics and Electrical, Ship in the Metal Cutting and Machine Tool - Global Market:

The usage of metal cutting and machine tools spans across several key industries, each with its unique requirements and applications. In the automotive industry, these tools are essential for manufacturing various components, from engine parts to body panels. Precision and efficiency are critical in this sector, as manufacturers strive to produce high-quality vehicles at competitive prices. Metal cutting tools enable the production of complex shapes and designs, ensuring that each component meets stringent quality standards. In the aerospace and defense industries, the demand for metal cutting and machine tools is driven by the need for lightweight, durable, and high-performance components. These tools are used to manufacture parts for aircraft, spacecraft, and military equipment, where precision and reliability are paramount. The ability to work with advanced materials, such as titanium and composites, is crucial in these industries, and metal cutting tools play a vital role in achieving the desired specifications. In the architecture and construction sectors, metal cutting tools are used to fabricate structural components, decorative elements, and fixtures. The ability to cut and shape metal with precision allows architects and builders to create innovative designs and ensure the structural integrity of buildings and infrastructure. In the electronics and electrical industries, metal cutting tools are used to produce components for devices such as smartphones, computers, and appliances. The demand for miniaturization and high-performance electronics drives the need for precise and efficient manufacturing processes, which metal cutting tools can provide. Lastly, in the shipbuilding industry, metal cutting tools are used to construct the hulls and superstructures of ships, as well as various components and fittings. The ability to cut and shape large metal sheets with precision and speed is essential in this industry, where efficiency and durability are key considerations. Overall, the global market for metal cutting and machine tools is integral to the success of these industries, providing the necessary technology and capabilities to meet their diverse needs.

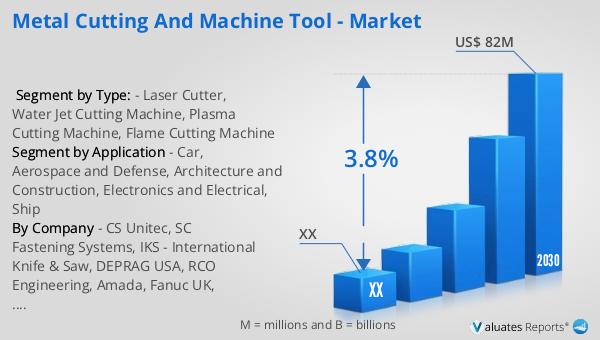

Metal Cutting and Machine Tool - Global Market Outlook:

The global market for metal cutting and machine tools was valued at approximately $64 million in 2023. This market is projected to grow steadily, reaching an estimated size of $82 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. The increasing demand for precision manufacturing and the adoption of advanced technologies in various industries are key factors driving this growth. As industries continue to evolve and embrace automation and digitalization, the need for efficient and high-quality metal cutting and machine tools is expected to rise. This market outlook highlights the importance of these tools in supporting the manufacturing processes of diverse industries, from automotive to aerospace and beyond. The projected growth reflects the ongoing advancements in technology and the increasing complexity of manufacturing requirements, which necessitate the use of sophisticated metal cutting and machine tools. As the market continues to expand, manufacturers and suppliers will need to focus on innovation and quality to meet the evolving needs of their customers and maintain a competitive edge in the global market.

| Report Metric | Details |

| Report Name | Metal Cutting and Machine Tool - Market |

| Forecasted market size in 2030 | US$ 82 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | CS Unitec, SC Fastening Systems, IKS - International Knife & Saw, DEPRAG USA, RCO Engineering, Amada, Fanuc UK, Nachi-Fujikoshi Corp, Sandvik AB, Ceratizit Group, Yamazaki Mazak, Okuma, DMG MORI, JTEKT, Komatsu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |