What is Hydraulic Blacksmith - Global Market?

Hydraulic blacksmithing is a specialized field within the global market that focuses on the use of hydraulic machinery to forge and shape metal. This market encompasses a range of equipment and technologies designed to enhance the efficiency and precision of metalworking processes. Hydraulic blacksmiths utilize hydraulic presses, hammers, and other tools to manipulate metal with great force, allowing for the creation of intricate designs and robust structures. The global market for hydraulic blacksmithing is driven by the demand for high-quality metal products in various industries, including construction, automotive, and manufacturing. As industries continue to seek innovative solutions for metal fabrication, the hydraulic blacksmith market is poised for growth, offering advanced machinery that meets the evolving needs of modern metalworking. The integration of hydraulic technology in blacksmithing not only improves productivity but also ensures consistent quality in the final products, making it an essential component of the global metalworking industry.

Single Cylinder Hydraulic, Double Cylinder Hydraulic in the Hydraulic Blacksmith - Global Market:

In the realm of hydraulic blacksmithing, single-cylinder and double-cylinder hydraulic systems play pivotal roles, each offering distinct advantages and applications. Single-cylinder hydraulic systems are characterized by their simplicity and efficiency, making them ideal for tasks that require straightforward force application. These systems consist of a single hydraulic cylinder that generates force through the movement of a piston within a cylinder, driven by hydraulic fluid. This design is particularly advantageous for operations that demand precise control and consistent pressure, such as bending, punching, and forming metal components. Single-cylinder systems are often favored in smaller workshops or for specific tasks where space and budget constraints are considerations. On the other hand, double-cylinder hydraulic systems offer enhanced power and versatility, making them suitable for more demanding applications. These systems incorporate two hydraulic cylinders, which can work in tandem to deliver greater force and control. This dual-cylinder configuration is particularly beneficial in heavy-duty forging and shaping processes, where the ability to exert substantial pressure is crucial. Double-cylinder systems are commonly employed in large-scale industrial settings, where the need for robust and reliable machinery is paramount. The choice between single and double-cylinder hydraulic systems in the hydraulic blacksmith market depends on the specific requirements of the task at hand, as well as the scale and complexity of the operation. Both systems contribute significantly to the efficiency and effectiveness of metalworking processes, offering solutions that cater to a wide range of industrial needs. As the global market for hydraulic blacksmithing continues to evolve, the demand for both single and double-cylinder systems is expected to grow, driven by the increasing need for precision and power in metal fabrication. The versatility and adaptability of these systems make them indispensable tools in the modern blacksmith's arsenal, enabling the creation of high-quality metal products with precision and efficiency.

Construction Industry, Metal Fabrication, Oil and Gas, Others in the Hydraulic Blacksmith - Global Market:

The usage of hydraulic blacksmithing in various industries highlights its versatility and importance in modern manufacturing and construction. In the construction industry, hydraulic blacksmithing plays a crucial role in the fabrication of structural components, such as beams, columns, and connectors. The ability to shape and form metal with precision ensures that these components meet the stringent safety and quality standards required in construction projects. Hydraulic blacksmithing also facilitates the creation of custom metalwork, allowing architects and builders to incorporate unique designs and features into their structures. In the metal fabrication industry, hydraulic blacksmithing is essential for producing a wide range of metal products, from simple brackets and fasteners to complex machinery parts. The precision and control offered by hydraulic systems enable fabricators to achieve intricate designs and tight tolerances, ensuring that the final products meet the exact specifications required by their clients. In the oil and gas industry, hydraulic blacksmithing is used to manufacture components that must withstand extreme conditions, such as high pressure and temperature. The durability and strength of metal products forged through hydraulic blacksmithing make them ideal for use in pipelines, drilling equipment, and other critical infrastructure. Additionally, hydraulic blacksmithing is employed in various other industries, including automotive, aerospace, and defense, where the demand for high-quality metal components is ever-present. The adaptability of hydraulic blacksmithing to different applications and industries underscores its significance in the global market, providing solutions that enhance the efficiency and quality of metalworking processes across diverse sectors.

Hydraulic Blacksmith - Global Market Outlook:

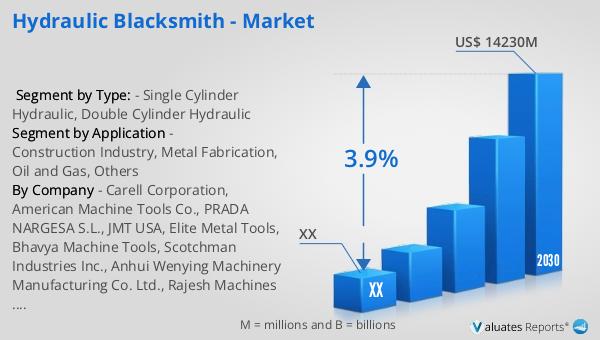

The global market for hydraulic blacksmithing was valued at approximately $10,890 million in 2023, with projections indicating a growth to around $14,230 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. The North American segment of this market was also valued at a significant amount in 2023, with expectations of continued growth through 2030. Although specific figures for the North American market are not provided, the overall trend suggests a positive outlook for hydraulic blacksmithing in this region. The anticipated growth in the global market can be attributed to the increasing demand for advanced metalworking solutions across various industries, including construction, automotive, and manufacturing. As industries continue to seek innovative and efficient methods for metal fabrication, the hydraulic blacksmith market is poised to expand, offering cutting-edge machinery and technologies that meet the evolving needs of modern metalworking. The integration of hydraulic technology in blacksmithing not only enhances productivity but also ensures consistent quality in the final products, making it an essential component of the global metalworking industry.

| Report Metric | Details |

| Report Name | Hydraulic Blacksmith - Market |

| Forecasted market size in 2030 | US$ 14230 million |

| CAGR | 3.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Carell Corporation, American Machine Tools Co., PRADA NARGESA S.L., JMT USA, Elite Metal Tools, Bhavya Machine Tools, Scotchman Industries Inc., Anhui Wenying Machinery Manufacturing Co. Ltd., Rajesh Machines India LLP, Nargesa, GEKA Group, Masko Tech Engineers, Sunrise Fluid Power Inc., Jinan DP Info Tech Co. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |