What is Global Vanadium Oxide Infrared Detector Chips Market?

The Global Vanadium Oxide Infrared Detector Chips Market is a specialized segment within the broader infrared detector industry. These chips are integral components used in various infrared detection systems, leveraging the unique properties of vanadium oxide to sense infrared radiation. Vanadium oxide is particularly valued for its ability to change resistance with temperature, making it an ideal material for thermal imaging applications. These detector chips are used in a wide range of applications, from night vision equipment and thermal cameras to industrial monitoring systems and scientific research tools. The market for these chips is driven by the increasing demand for advanced surveillance and security systems, as well as the growing adoption of infrared technology in consumer electronics and automotive sectors. As technology advances, the efficiency and sensitivity of these chips continue to improve, expanding their potential applications and driving market growth. The market is characterized by ongoing research and development efforts aimed at enhancing the performance and reducing the cost of these chips, making them more accessible for various applications. The global market for vanadium oxide infrared detector chips is poised for steady growth, reflecting the increasing importance of infrared technology in modern society.

Wafer Level Packaging, Metal Packaging, Ceramic Packaging in the Global Vanadium Oxide Infrared Detector Chips Market:

Wafer Level Packaging (WLP), Metal Packaging, and Ceramic Packaging are three distinct methods used in the packaging of Global Vanadium Oxide Infrared Detector Chips, each offering unique benefits and challenges. Wafer Level Packaging is a cutting-edge technology that involves packaging the entire wafer of chips before they are diced into individual units. This method is highly efficient and cost-effective, as it allows for the simultaneous packaging of multiple chips, reducing the overall production time and cost. WLP is particularly advantageous for vanadium oxide infrared detector chips as it provides excellent thermal management and electrical performance, which are critical for maintaining the sensitivity and accuracy of these detectors. Additionally, WLP offers a compact form factor, which is essential for applications where space is limited, such as in portable devices and compact surveillance systems. However, the initial setup cost for WLP can be high, and it requires sophisticated equipment and expertise, which can be a barrier for smaller manufacturers. Metal Packaging, on the other hand, is a more traditional approach that involves encasing the detector chips in metal enclosures. This method provides robust protection against environmental factors such as moisture, dust, and mechanical stress, making it ideal for applications in harsh environments. Metal packaging is known for its durability and reliability, ensuring the longevity of the vanadium oxide infrared detector chips. It also offers excellent electromagnetic shielding, which is crucial for maintaining the integrity of the signals processed by the detectors. However, metal packaging can be bulkier compared to other methods, which may not be suitable for applications where size and weight are critical considerations. Additionally, the thermal conductivity of metal packaging can sometimes lead to overheating issues, which need to be carefully managed to prevent damage to the chips. Ceramic Packaging is another popular method used for vanadium oxide infrared detector chips, known for its superior thermal and electrical insulation properties. Ceramic materials are highly resistant to temperature fluctuations and chemical corrosion, making them ideal for applications that require high reliability and stability. Ceramic packaging provides excellent protection for the chips, ensuring their performance in demanding conditions such as high-temperature environments or in applications involving corrosive substances. The inherent rigidity and strength of ceramic materials also offer mechanical protection, reducing the risk of damage during handling and operation. However, ceramic packaging can be more expensive than other methods, and the manufacturing process can be more complex, requiring specialized equipment and expertise. Despite these challenges, the benefits of ceramic packaging, particularly in terms of thermal management and reliability, make it a preferred choice for high-performance applications. In summary, the choice of packaging method for Global Vanadium Oxide Infrared Detector Chips depends on the specific requirements of the application, including factors such as cost, size, environmental conditions, and performance needs. Wafer Level Packaging offers efficiency and compactness, making it suitable for consumer electronics and portable devices. Metal Packaging provides robust protection and reliability, ideal for industrial and defense applications. Ceramic Packaging offers superior thermal and chemical resistance, making it suitable for high-performance and demanding environments. Each packaging method has its own set of advantages and challenges, and manufacturers must carefully consider these factors when selecting the appropriate packaging solution for their vanadium oxide infrared detector chips.

Self-produced and Used, Commercial, Defense in the Global Vanadium Oxide Infrared Detector Chips Market:

The usage of Global Vanadium Oxide Infrared Detector Chips spans across various sectors, including self-produced and used applications, commercial uses, and defense. In self-produced and used applications, these chips are often utilized by companies and research institutions that develop their own infrared detection systems. These organizations leverage the unique properties of vanadium oxide to create customized solutions tailored to their specific needs. For instance, research laboratories may use these chips in scientific instruments for thermal imaging and spectroscopy, enabling precise measurements and analysis. Similarly, companies involved in the development of advanced surveillance systems may integrate these chips into their products to enhance their performance and capabilities. The ability to self-produce and use these chips allows organizations to maintain control over the design and functionality of their infrared detection systems, ensuring they meet their exact requirements. In the commercial sector, vanadium oxide infrared detector chips are widely used in a variety of applications, ranging from consumer electronics to industrial monitoring systems. In consumer electronics, these chips are often found in devices such as smartphones and tablets, where they enable features like facial recognition and gesture control. The growing demand for smart home devices and wearable technology has also driven the adoption of these chips, as they provide the necessary infrared sensing capabilities for these applications. In industrial settings, vanadium oxide infrared detector chips are used in monitoring systems for temperature measurement, process control, and equipment maintenance. These chips enable real-time monitoring and analysis, helping companies optimize their operations and improve efficiency. The versatility and reliability of these chips make them an attractive option for a wide range of commercial applications. In the defense sector, vanadium oxide infrared detector chips play a crucial role in enhancing the capabilities of military and security systems. These chips are used in night vision equipment, thermal imaging cameras, and missile guidance systems, providing critical information for situational awareness and decision-making. The ability to detect and analyze infrared radiation is essential for military operations, as it allows for the identification of targets and threats in low-light or obscured environments. The high sensitivity and accuracy of vanadium oxide infrared detector chips make them an invaluable asset for defense applications, where precision and reliability are paramount. Additionally, these chips are used in border security and surveillance systems, helping to monitor and protect critical infrastructure and assets. The defense sector's demand for advanced infrared detection technology continues to drive the development and adoption of vanadium oxide infrared detector chips, ensuring they remain a key component in modern military and security systems. Overall, the usage of Global Vanadium Oxide Infrared Detector Chips in self-produced and used applications, commercial uses, and defense highlights their versatility and importance across various sectors. These chips provide the necessary infrared sensing capabilities for a wide range of applications, from scientific research and consumer electronics to industrial monitoring and military operations. The ongoing advancements in infrared technology and the increasing demand for high-performance detection systems continue to drive the growth and adoption of vanadium oxide infrared detector chips, ensuring their relevance and significance in the global market.

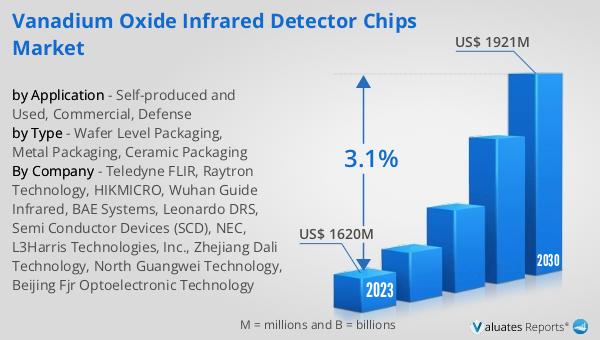

Global Vanadium Oxide Infrared Detector Chips Market Outlook:

The outlook for the Global Vanadium Oxide Infrared Detector Chips Market indicates a positive growth trajectory over the coming years. In 2023, the market was valued at approximately US$ 1,620 million, reflecting the significant demand for these specialized chips across various sectors. By 2030, the market is projected to reach around US$ 1,921 million, demonstrating a steady compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is driven by the increasing adoption of infrared technology in diverse applications, including consumer electronics, industrial monitoring, and defense systems. The unique properties of vanadium oxide, such as its ability to change resistance with temperature, make it an ideal material for infrared detection, contributing to the market's expansion. Additionally, ongoing research and development efforts aimed at enhancing the performance and reducing the cost of these chips are expected to further boost their adoption. As the demand for advanced surveillance and security systems continues to rise, the Global Vanadium Oxide Infrared Detector Chips Market is poised for sustained growth, reflecting the increasing importance of infrared technology in modern society. The market's positive outlook underscores the critical role these chips play in enabling a wide range of applications, from scientific research and consumer electronics to industrial monitoring and military operations.

| Report Metric | Details |

| Report Name | Vanadium Oxide Infrared Detector Chips Market |

| Accounted market size in 2023 | US$ 1620 million |

| Forecasted market size in 2030 | US$ 1921 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teledyne FLIR, Raytron Technology, HIKMICRO, Wuhan Guide Infrared, BAE Systems, Leonardo DRS, Semi Conductor Devices (SCD), NEC, L3Harris Technologies, Inc., Zhejiang Dali Technology, North Guangwei Technology, Beijing Fjr Optoelectronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |