What is Global Continuous Flow Microchannel Reactor Market?

The Global Continuous Flow Microchannel Reactor Market is a specialized segment within the broader chemical processing industry, focusing on the use of microchannel reactors for continuous flow processes. These reactors are designed with small channels, typically on the scale of micrometers, which allow for precise control over chemical reactions. This technology is gaining traction due to its ability to enhance reaction efficiency, improve safety, and reduce waste compared to traditional batch processing methods. The market is driven by the increasing demand for efficient and sustainable chemical processes across various industries, including pharmaceuticals, chemicals, and energy. Continuous flow microchannel reactors offer advantages such as faster reaction times, better heat and mass transfer, and the ability to scale up processes more easily. As industries seek to optimize production and reduce environmental impact, the adoption of these reactors is expected to grow. The market is characterized by ongoing research and development efforts to improve reactor designs and expand their applications. Companies operating in this space are focusing on innovation and collaboration to meet the evolving needs of their customers. Overall, the Global Continuous Flow Microchannel Reactor Market represents a promising area of growth and innovation in the field of chemical processing.

Lab-scale Flow Reactors, Production-scale Flow Reactors in the Global Continuous Flow Microchannel Reactor Market:

Lab-scale flow reactors and production-scale flow reactors are two critical components of the Global Continuous Flow Microchannel Reactor Market, each serving distinct purposes in the chemical processing industry. Lab-scale flow reactors are primarily used in research and development settings, where they facilitate the exploration of new chemical reactions and processes. These reactors are designed to handle small volumes of reactants, making them ideal for experimentation and optimization of reaction conditions. Researchers can use lab-scale flow reactors to test different catalysts, temperatures, and pressures to determine the most efficient and effective reaction pathways. The precise control offered by these reactors allows for the rapid screening of reaction parameters, enabling scientists to quickly identify optimal conditions for desired chemical transformations. Additionally, lab-scale flow reactors are instrumental in the development of new pharmaceuticals, as they allow for the synthesis of complex molecules in a controlled and reproducible manner. On the other hand, production-scale flow reactors are designed for industrial applications, where they are used to manufacture chemicals and pharmaceuticals on a larger scale. These reactors are capable of handling larger volumes of reactants and are often integrated into continuous production lines. Production-scale flow reactors offer several advantages over traditional batch reactors, including improved safety, reduced waste, and increased efficiency. By operating continuously, these reactors can produce chemicals more consistently and with higher yields, reducing the need for costly and time-consuming batch processing. The scalability of production-scale flow reactors also allows for the seamless transition from lab-scale experiments to full-scale manufacturing, enabling companies to bring new products to market more quickly. In the Global Continuous Flow Microchannel Reactor Market, both lab-scale and production-scale flow reactors play a vital role in advancing chemical processing technologies. As industries continue to seek more efficient and sustainable production methods, the demand for these reactors is expected to grow. Companies are investing in research and development to enhance the capabilities of both lab-scale and production-scale flow reactors, focusing on improving reactor designs, increasing throughput, and expanding the range of applications. The integration of advanced technologies, such as automation and data analytics, is also driving innovation in this market, enabling more precise control and monitoring of chemical processes. Overall, lab-scale and production-scale flow reactors are essential tools in the Global Continuous Flow Microchannel Reactor Market, supporting the development and commercialization of new chemical processes and products.

Chemicals, Pharmaceuticals, Others in the Global Continuous Flow Microchannel Reactor Market:

The Global Continuous Flow Microchannel Reactor Market finds extensive applications across various industries, including chemicals, pharmaceuticals, and others, due to its ability to enhance reaction efficiency and safety. In the chemical industry, continuous flow microchannel reactors are used to produce a wide range of chemicals, from basic raw materials to specialty chemicals. These reactors offer precise control over reaction conditions, allowing for the optimization of chemical processes and the production of high-quality products. The ability to operate continuously also reduces the risk of hazardous reactions and minimizes waste, making these reactors an attractive option for chemical manufacturers seeking to improve sustainability and reduce costs. In the pharmaceutical industry, continuous flow microchannel reactors are used to synthesize complex molecules and active pharmaceutical ingredients (APIs). The precise control offered by these reactors allows for the efficient and reproducible synthesis of pharmaceuticals, ensuring consistent product quality and reducing the risk of batch-to-batch variability. The ability to rapidly screen reaction conditions and optimize processes also accelerates the development of new drugs, enabling pharmaceutical companies to bring new treatments to market more quickly. Additionally, continuous flow microchannel reactors can be used to produce small quantities of highly potent compounds, which are often required in the development of personalized medicines and targeted therapies. Beyond chemicals and pharmaceuticals, continuous flow microchannel reactors are also used in other industries, such as energy and materials science. In the energy sector, these reactors are used to produce biofuels and other renewable energy sources, offering a more sustainable alternative to traditional fossil fuels. The ability to operate continuously and efficiently makes these reactors well-suited for large-scale production of biofuels, helping to reduce greenhouse gas emissions and dependence on non-renewable resources. In materials science, continuous flow microchannel reactors are used to synthesize advanced materials, such as nanoparticles and polymers, which have applications in electronics, coatings, and other high-tech industries. The precise control over reaction conditions allows for the production of materials with specific properties and characteristics, enabling the development of innovative products and technologies. Overall, the Global Continuous Flow Microchannel Reactor Market plays a crucial role in advancing chemical processing technologies across a wide range of industries. As companies continue to seek more efficient and sustainable production methods, the adoption of continuous flow microchannel reactors is expected to grow, driving innovation and growth in this dynamic market.

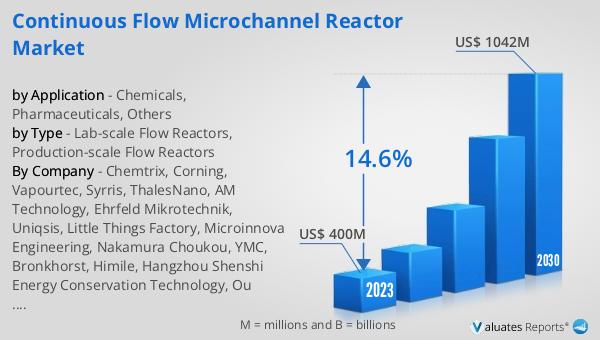

Global Continuous Flow Microchannel Reactor Market Outlook:

In 2023, the Global Continuous Flow Microchannel Reactor Market was valued at approximately $400 million. This market is projected to experience significant growth over the coming years, with expectations to reach around $1,042 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 14.6% during the forecast period from 2024 to 2030. The increasing demand for efficient and sustainable chemical processing solutions is a key driver of this market expansion. Continuous flow microchannel reactors offer numerous advantages over traditional batch processing methods, including improved reaction efficiency, enhanced safety, and reduced waste. These benefits are particularly appealing to industries such as chemicals and pharmaceuticals, where there is a constant push for innovation and optimization. As companies strive to meet the growing demand for high-quality products while minimizing environmental impact, the adoption of continuous flow microchannel reactors is expected to rise. Additionally, ongoing research and development efforts are likely to further enhance the capabilities of these reactors, expanding their applications and driving market growth. The Global Continuous Flow Microchannel Reactor Market represents a promising area of opportunity for companies looking to capitalize on the increasing demand for advanced chemical processing technologies. With a strong growth outlook and a focus on innovation, this market is poised to play a significant role in shaping the future of the chemical processing industry.

| Report Metric | Details |

| Report Name | Continuous Flow Microchannel Reactor Market |

| Accounted market size in 2023 | US$ 400 million |

| Forecasted market size in 2030 | US$ 1042 million |

| CAGR | 14.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Chemtrix, Corning, Vapourtec, Syrris, ThalesNano, AM Technology, Ehrfeld Mikrotechnik, Uniqsis, Little Things Factory, Microinnova Engineering, Nakamura Choukou, YMC, Bronkhorst, Himile, Hangzhou Shenshi Energy Conservation Technology, Ou Shisheng Technology, Micro-chemical Technology, Taizhou Pudu Machinery, Shandong Weijing FLOWCHEM, Hybrid-Chem Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |