What is Glass Bead Abrasive - Global Market?

Glass bead abrasive is a versatile material used in various industries for surface finishing and cleaning applications. These tiny, spherical glass particles are employed in processes like sandblasting, where they help in removing surface contaminants, rust, and paint without damaging the underlying material. The global market for glass bead abrasive is driven by its widespread use in industries such as automotive, aerospace, and construction, where precision and surface integrity are crucial. The demand for glass bead abrasive is also fueled by its eco-friendly nature, as it can be recycled and reused multiple times, reducing waste and environmental impact. Additionally, glass bead abrasive is preferred for its ability to produce a smooth, satin-like finish, making it ideal for applications where aesthetics are important. The market is characterized by a diverse range of products, varying in size and composition, to cater to different industrial needs. As industries continue to prioritize sustainability and efficiency, the demand for glass bead abrasive is expected to grow, driven by advancements in manufacturing technologies and the increasing adoption of environmentally friendly practices. Overall, the global market for glass bead abrasive is poised for steady growth, supported by its versatility and eco-friendly attributes.

850-600µm, 600-425µm, 425-250µm, 250-180µm, 250-150µm, 150-106µm, 106-90µm, 90-44µm, Others in the Glass Bead Abrasive - Global Market:

The global market for glass bead abrasive is segmented based on particle size, which plays a crucial role in determining its application and effectiveness. The size range of 850-600µm is typically used for heavy-duty cleaning and surface preparation, where a more aggressive abrasive action is required. This size is ideal for removing thick coatings, rust, and other stubborn contaminants from metal surfaces. The 600-425µm range is slightly less aggressive and is often used for general-purpose cleaning and surface preparation tasks. It is suitable for applications where a balance between cleaning power and surface preservation is needed. The 425-250µm size range is commonly used for finer cleaning tasks, such as removing light rust or paint from delicate surfaces. This size is preferred in industries where precision is paramount, such as aerospace and electronics. The 250-180µm range is used for even finer applications, where minimal surface disruption is desired. This size is often employed in the medical industry for cleaning surgical instruments and other sensitive equipment. The 250-150µm range is used for precision cleaning and finishing tasks, where a smooth surface finish is required. This size is popular in the automotive industry for preparing surfaces for painting or coating. The 150-106µm range is used for ultra-fine cleaning and finishing applications, where a high degree of surface smoothness is required. This size is often used in the electronics industry for cleaning circuit boards and other delicate components. The 106-90µm range is used for micro-abrasive applications, where precision and control are critical. This size is commonly used in the aerospace industry for cleaning and finishing turbine blades and other high-precision components. The 90-44µm range is used for the finest abrasive applications, where minimal surface disruption is required. This size is often used in the medical industry for cleaning and finishing delicate instruments and implants. Other sizes are available for specialized applications, where specific surface characteristics are required. The choice of glass bead size depends on the specific requirements of the application, including the type of material being cleaned, the desired surface finish, and the level of precision required. As industries continue to demand higher levels of precision and surface quality, the market for glass bead abrasive is expected to grow, driven by advancements in manufacturing technologies and the increasing adoption of environmentally friendly practices.

Automobile, Medical, Aerospace in the Glass Bead Abrasive - Global Market:

Glass bead abrasive is widely used in the automotive, medical, and aerospace industries due to its versatility and effectiveness in surface finishing and cleaning applications. In the automotive industry, glass bead abrasive is used for cleaning and preparing surfaces for painting or coating. It is particularly effective in removing rust, paint, and other contaminants from metal surfaces without causing damage. This makes it ideal for use in automotive restoration and repair, where preserving the integrity of the underlying material is crucial. Additionally, glass bead abrasive is used for peening, a process that improves the fatigue resistance of metal components by inducing compressive stresses on the surface. This is particularly important in the automotive industry, where components are subjected to high levels of stress and wear. In the medical industry, glass bead abrasive is used for cleaning and finishing surgical instruments and other sensitive equipment. Its ability to produce a smooth, satin-like finish makes it ideal for applications where hygiene and precision are paramount. Glass bead abrasive is also used in the production of medical implants, where a high degree of surface smoothness is required to ensure proper integration with the body. In the aerospace industry, glass bead abrasive is used for cleaning and finishing high-precision components, such as turbine blades and engine parts. Its ability to remove surface contaminants without causing damage makes it ideal for use in the aerospace industry, where precision and reliability are critical. Additionally, glass bead abrasive is used for peening, a process that improves the fatigue resistance of metal components by inducing compressive stresses on the surface. This is particularly important in the aerospace industry, where components are subjected to high levels of stress and wear. Overall, the use of glass bead abrasive in these industries is driven by its ability to provide a high-quality surface finish while minimizing environmental impact. As industries continue to prioritize sustainability and efficiency, the demand for glass bead abrasive is expected to grow, supported by advancements in manufacturing technologies and the increasing adoption of environmentally friendly practices.

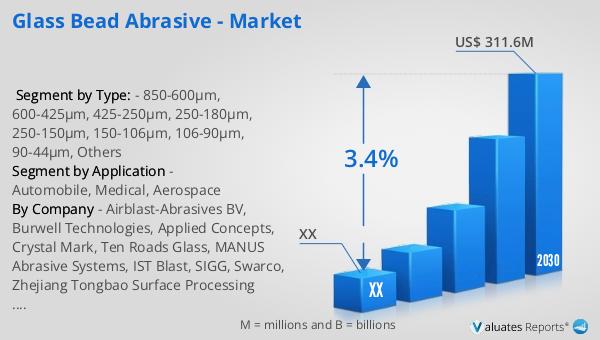

Glass Bead Abrasive - Global Market Outlook:

In 2023, the global market for glass bead abrasive was valued at approximately $237 million. Looking ahead, projections indicate that by 2030, this market is expected to expand to a revised size of around $311.6 million. This growth trajectory reflects a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This steady growth can be attributed to the increasing demand for glass bead abrasive across various industries, driven by its versatility and eco-friendly nature. As industries continue to prioritize sustainability and efficiency, the adoption of glass bead abrasive is expected to rise, supported by advancements in manufacturing technologies and the increasing adoption of environmentally friendly practices. The market's expansion is also fueled by the growing need for precision and surface quality in industries such as automotive, aerospace, and medical. As these industries continue to evolve and demand higher levels of performance and reliability, the market for glass bead abrasive is poised for steady growth. Overall, the global market for glass bead abrasive is expected to experience a positive growth trajectory, driven by its versatility and eco-friendly attributes.

| Report Metric | Details |

| Report Name | Glass Bead Abrasive - Market |

| Forecasted market size in 2030 | US$ 311.6 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Airblast-Abrasives BV, Burwell Technologies, Applied Concepts, Crystal Mark, Ten Roads Glass, MANUS Abrasive Systems, IST Blast, SIGG, Swarco, Zhejiang Tongbao Surface Processing Equipment Technology, Pellets LLC, Luanxian Sanlian Glass Beads Co. Ltd., Yongqing Huayang Glass Products Co. Ltd., Luoyang Zhongsen Refractory Co. Limited, Zhengzhou Haixu Abrasives Co. Ltd., SICHENG ABRASIVES, Suzhou Jinxing Abrasives Co. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |