What is Expandable Polystyrene (EPS) Bead - Global Market?

Expandable Polystyrene (EPS) beads are a type of plastic material that has gained significant traction in the global market due to their versatile applications and beneficial properties. EPS beads are small, lightweight, and composed of polystyrene, a type of plastic that can be expanded and molded into various shapes. These beads are primarily used in the production of foam products, which are known for their excellent insulation properties, lightweight nature, and shock-absorbing capabilities. The global market for EPS beads is driven by their widespread use in industries such as construction, packaging, and electronics. In construction, EPS beads are used for insulation panels, helping to improve energy efficiency in buildings. In packaging, they provide cushioning and protection for goods during transportation. The electronics industry utilizes EPS beads for their insulating properties, protecting sensitive components from damage. The demand for EPS beads is expected to grow as industries continue to seek materials that offer both performance and cost-effectiveness. The market is also influenced by environmental considerations, with efforts to improve the recyclability and sustainability of EPS products. Overall, the global market for EPS beads is poised for growth, driven by their diverse applications and the ongoing need for efficient and sustainable materials.

White Expanded Polystyrene, Grey Expanded Polystyrene, Black Expanded Polystyrene in the Expandable Polystyrene (EPS) Bead - Global Market:

White Expanded Polystyrene (EPS) is the most common form of EPS and is widely used across various industries due to its excellent insulation properties and cost-effectiveness. It is composed of small, spherical beads that are expanded and fused together to form a rigid foam material. White EPS is primarily used in the construction industry for insulation panels, roofing, and floor systems, as it provides effective thermal insulation and helps reduce energy consumption in buildings. Its lightweight nature also makes it easy to handle and install, further contributing to its popularity in construction applications. In the packaging industry, white EPS is used to create protective packaging for a wide range of products, from electronics to food items. Its shock-absorbing properties help prevent damage during transportation, ensuring that goods arrive at their destination in good condition. Additionally, white EPS is used in the production of disposable food containers and cups, as it is resistant to moisture and provides good thermal insulation, keeping food and beverages at the desired temperature. Grey Expanded Polystyrene, on the other hand, is a variant of EPS that incorporates graphite particles into the beads, giving it a distinctive grey color. The addition of graphite enhances the thermal insulation properties of the material, making it even more effective at reducing heat transfer. This makes grey EPS particularly suitable for use in energy-efficient building applications, where superior insulation performance is required. It is often used in the construction of passive houses and other energy-efficient buildings, where minimizing heat loss is a priority. The improved insulation properties of grey EPS also make it an attractive option for use in cold storage facilities and refrigerated transport, where maintaining a consistent temperature is crucial. Black Expanded Polystyrene is another variant of EPS that is gaining popularity in the global market. Like grey EPS, black EPS incorporates additives that enhance its thermal insulation properties. The black color is typically achieved through the addition of carbon black or other pigments, which also provide UV resistance, making black EPS suitable for outdoor applications. In the construction industry, black EPS is used for insulation in roofing and exterior wall systems, where its UV resistance helps extend the lifespan of the material. It is also used in the production of lightweight concrete, where it acts as an aggregate, reducing the overall weight of the concrete while maintaining its structural integrity. In the packaging industry, black EPS is used for high-end packaging applications, where its aesthetic appeal and superior insulation properties are valued. Overall, the global market for white, grey, and black EPS is driven by their unique properties and the diverse range of applications they serve. As industries continue to seek materials that offer both performance and sustainability, the demand for these variants of EPS is expected to grow.

Building Construction, Electrical and Electronics, Packaging, Other in the Expandable Polystyrene (EPS) Bead - Global Market:

Expandable Polystyrene (EPS) beads are widely used in the building construction industry due to their excellent insulation properties and lightweight nature. In construction, EPS beads are used to produce insulation panels, which are installed in walls, roofs, and floors to improve the energy efficiency of buildings. These panels help reduce heat transfer, keeping buildings warm in the winter and cool in the summer, thereby reducing the need for heating and cooling systems and lowering energy costs. EPS beads are also used in the production of lightweight concrete, where they act as an aggregate, reducing the overall weight of the concrete while maintaining its structural integrity. This makes EPS concrete ideal for use in applications where weight is a concern, such as in high-rise buildings and bridges. In the electrical and electronics industry, EPS beads are used for their insulating properties, protecting sensitive components from damage due to heat and electrical interference. EPS is used to produce packaging for electronic devices, providing cushioning and protection during transportation. It is also used in the production of insulation for electrical cables and components, helping to prevent heat buildup and improve the efficiency of electrical systems. In the packaging industry, EPS beads are used to create protective packaging for a wide range of products, from electronics to food items. EPS packaging is lightweight, shock-absorbing, and moisture-resistant, making it ideal for protecting goods during transportation. It is also used in the production of disposable food containers and cups, as it provides good thermal insulation, keeping food and beverages at the desired temperature. In addition to these industries, EPS beads are used in a variety of other applications, including the production of flotation devices, such as life jackets and buoys, due to their buoyant properties. They are also used in the production of decorative items, such as architectural moldings and props, due to their lightweight nature and ease of shaping. Overall, the global market for EPS beads is driven by their versatile applications and beneficial properties, making them a popular choice in a wide range of industries.

Expandable Polystyrene (EPS) Bead - Global Market Outlook:

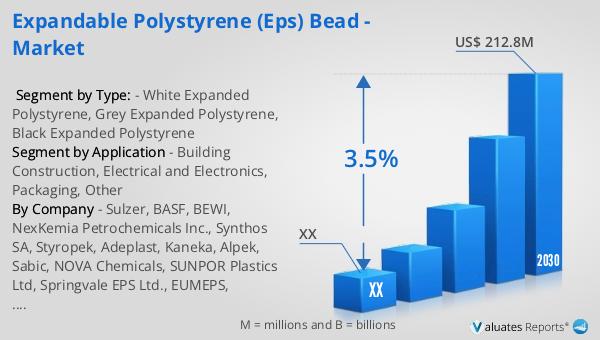

In 2023, the global market for Expandable Polystyrene (EPS) beads was valued at approximately $158.4 million. Looking ahead, this market is projected to grow, reaching an estimated size of $212.8 million by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. This indicates a steady increase in demand for EPS beads across various industries, driven by their versatile applications and beneficial properties. The North American market, in particular, is expected to play a significant role in this growth, as industries in the region continue to seek materials that offer both performance and cost-effectiveness. The demand for EPS beads is also influenced by environmental considerations, with efforts to improve the recyclability and sustainability of EPS products. As industries continue to prioritize sustainability and efficiency, the global market for EPS beads is poised for growth, driven by their diverse applications and the ongoing need for efficient and sustainable materials. Overall, the market outlook for EPS beads is positive, with steady growth expected in the coming years.

| Report Metric | Details |

| Report Name | Expandable Polystyrene (EPS) Bead - Market |

| Forecasted market size in 2030 | US$ 212.8 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Sulzer, BASF, BEWI, NexKemia Petrochemicals Inc., Synthos SA, Styropek, Adeplast, Kaneka, Alpek, Sabic, NOVA Chemicals, SUNPOR Plastics Ltd, Springvale EPS Ltd., EUMEPS, Vertapak, Aschem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |