What is Crane Counterweight - Global Market?

Crane counterweights are essential components in the global market, playing a crucial role in the safe and efficient operation of cranes. These counterweights are used to balance the crane's load, ensuring stability and preventing tipping during lifting operations. The global market for crane counterweights is driven by the increasing demand for construction and infrastructure development worldwide. As urbanization and industrialization continue to rise, the need for cranes in various sectors such as construction, shipping, and manufacturing has surged, subsequently boosting the demand for crane counterweights. These counterweights are typically made from materials like concrete, cast iron, and lead, each offering different benefits in terms of weight, cost, and durability. The market is also influenced by technological advancements that aim to improve the efficiency and safety of crane operations. As industries strive for more sustainable and cost-effective solutions, the crane counterweight market is expected to evolve, with manufacturers focusing on innovative materials and designs to meet the changing needs of their clients. The global market for crane counterweights is a dynamic and essential part of the construction and industrial sectors, ensuring that cranes operate safely and efficiently across various applications.

Concrete Counterweight, Cast Iron Counterweight, Lead Weight, Others in the Crane Counterweight - Global Market:

Concrete counterweights are among the most commonly used types in the crane counterweight market. They are favored for their cost-effectiveness and ease of production. Concrete is a versatile material that can be molded into various shapes and sizes, making it ideal for custom counterweight solutions. These counterweights are often used in construction sites where large, heavy loads need to be lifted. The density of concrete provides the necessary weight to balance the crane, ensuring stability during operations. However, concrete counterweights can be bulky and may require additional handling equipment for transportation and installation. Cast iron counterweights, on the other hand, offer a higher density than concrete, allowing for a more compact design. This makes them suitable for applications where space is limited, such as in urban construction sites. Cast iron is also highly durable and resistant to environmental factors, making it a long-lasting option for crane counterweights. Despite their higher cost compared to concrete, the durability and compactness of cast iron counterweights make them a popular choice in the market. Lead weights are another option in the crane counterweight market, known for their high density and compact size. Lead is one of the densest materials available, allowing for the creation of small yet heavy counterweights. This is particularly useful in applications where space is at a premium, and a high weight is required. However, the use of lead is often limited due to environmental and health concerns, as lead is a toxic material. As a result, the market for lead counterweights is more niche, with manufacturers and users seeking alternative materials that offer similar benefits without the associated risks. In addition to these primary materials, the crane counterweight market also includes other materials and innovative solutions. Some manufacturers are exploring the use of composite materials, which combine the benefits of different materials to create lightweight yet strong counterweights. These composites can offer improved performance and reduced environmental impact, aligning with the growing demand for sustainable construction practices. The choice of material for crane counterweights depends on various factors, including the specific application, budget, and environmental considerations. As the global market for crane counterweights continues to grow, manufacturers are likely to focus on developing new materials and technologies to meet the evolving needs of their customers.

Port, Construction Site, Others in the Crane Counterweight - Global Market:

Crane counterweights are utilized in various sectors, including ports, construction sites, and other industries, to ensure the safe and efficient operation of cranes. In ports, cranes are essential for loading and unloading cargo from ships. The use of counterweights in port cranes is crucial to balance the heavy loads being lifted, preventing accidents and ensuring smooth operations. Ports often handle a wide range of cargo, from containers to bulk goods, requiring cranes with varying lifting capacities. Counterweights help stabilize these cranes, allowing them to handle different types of cargo safely and efficiently. The demand for crane counterweights in ports is driven by the increasing global trade and the need for efficient logistics solutions. In construction sites, cranes are used for lifting and moving heavy materials such as steel beams, concrete blocks, and prefabricated structures. Counterweights are essential in these operations to maintain the crane's stability and prevent tipping. Construction projects often involve working in challenging environments, such as high-rise buildings or confined spaces, where the risk of accidents is higher. The use of counterweights ensures that cranes can operate safely in these conditions, reducing the risk of accidents and improving overall efficiency. The construction industry's growth, driven by urbanization and infrastructure development, has led to an increased demand for crane counterweights. Beyond ports and construction sites, crane counterweights are also used in other industries such as manufacturing, mining, and energy. In manufacturing, cranes are used to move heavy machinery and equipment, requiring counterweights to ensure stability during lifting operations. In the mining industry, cranes are used to transport heavy materials and equipment, often in challenging environments. Counterweights help maintain the crane's balance, ensuring safe and efficient operations. In the energy sector, cranes are used for the installation and maintenance of wind turbines, solar panels, and other infrastructure. The use of counterweights in these applications is crucial to ensure the safe and efficient handling of heavy components. The versatility and importance of crane counterweights across various industries highlight their critical role in ensuring the safe and efficient operation of cranes. As industries continue to evolve and demand more efficient and sustainable solutions, the market for crane counterweights is expected to grow, with manufacturers focusing on developing innovative materials and technologies to meet the changing needs of their customers.

Crane Counterweight - Global Market Outlook:

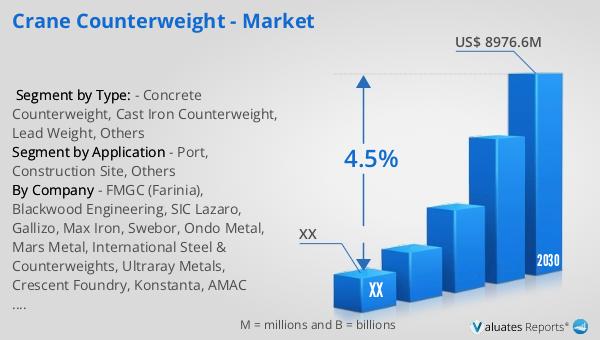

In 2023, the global market for crane counterweights was valued at approximately $6.8 billion. This market is projected to grow significantly, reaching an estimated size of $8.976 billion by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. The increasing demand for crane counterweights is driven by the rising need for construction and infrastructure development worldwide. As urbanization and industrialization continue to expand, the demand for cranes in various sectors such as construction, shipping, and manufacturing has surged, subsequently boosting the demand for crane counterweights. The market is also influenced by technological advancements that aim to improve the efficiency and safety of crane operations. As industries strive for more sustainable and cost-effective solutions, the crane counterweight market is expected to evolve, with manufacturers focusing on innovative materials and designs to meet the changing needs of their clients. The global market for crane counterweights is a dynamic and essential part of the construction and industrial sectors, ensuring that cranes operate safely and efficiently across various applications.

| Report Metric | Details |

| Report Name | Crane Counterweight - Market |

| Forecasted market size in 2030 | US$ 8976.6 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FMGC (Farinia), Blackwood Engineering, SIC Lazaro, Gallizo, Max Iron, Swebor, Ondo Metal, Mars Metal, International Steel & Counterweights, Ultraray Metals, Crescent Foundry, Konstanta, AMAC Alloys, Huaining County Hengyuan Renewable Technology, Agescan International, Innotec, Zunhua Wanxin Construction Machinery, LB Steel, Hameco, Farinia Group, Viet Nam Cast Iron |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |