What is Container Chassis for Container Transport - Global Market?

Container chassis are essential components in the global logistics and transportation industry, specifically designed for the efficient movement of shipping containers. These chassis are specialized trailers that provide a framework to support and transport containers, which are standardized cargo units used worldwide for shipping goods. The global market for container chassis is driven by the increasing demand for efficient and reliable transportation solutions, as international trade continues to grow. Container chassis come in various types, each designed to accommodate different container sizes and weights, ensuring flexibility and adaptability in transport operations. The market is characterized by technological advancements aimed at enhancing the durability, safety, and efficiency of these chassis. As global trade expands, the need for robust and versatile container chassis becomes more pronounced, making them a critical component in the supply chain. The market outlook for container chassis is promising, with steady growth anticipated as industries continue to rely on containerized shipping for their logistical needs. This growth is supported by the ongoing development of infrastructure and the adoption of innovative technologies that improve the performance and sustainability of container chassis.

Tilt Container Chassis, Extendable Container Chassis, Common Container Chassis in the Container Chassis for Container Transport - Global Market:

Tilt container chassis, extendable container chassis, and common container chassis are three primary types of chassis used in the global market for container transport, each serving distinct purposes. Tilt container chassis are designed to facilitate the loading and unloading of containers by allowing the chassis to tilt, making it easier to slide containers on and off. This type of chassis is particularly useful in areas where loading docks are not available, or when dealing with heavy or awkwardly shaped cargo that requires a more flexible loading approach. Tilt chassis are equipped with hydraulic systems that enable the tilting mechanism, providing a practical solution for challenging loading scenarios. Extendable container chassis, on the other hand, offer the flexibility to adjust their length to accommodate containers of varying sizes. This adaptability is crucial in a market where container dimensions can differ significantly, allowing transporters to efficiently handle both standard and non-standard container sizes. Extendable chassis are engineered with sliding mechanisms that enable the chassis to extend or retract, ensuring a secure fit for the container being transported. This type of chassis is ideal for operators who need to transport different container sizes without having to switch between multiple chassis types, thereby optimizing their fleet utilization. Common container chassis, also known as standard chassis, are the most widely used type in the industry. They are designed to transport standard-sized containers, typically 20-foot or 40-foot units, which are the most prevalent in global shipping. These chassis are built to provide a stable and secure platform for container transport, with features such as twist locks to hold the container in place during transit. Common chassis are favored for their simplicity, cost-effectiveness, and ease of maintenance, making them a staple in the container transport industry. Despite their straightforward design, common chassis are continually being improved with advancements in materials and engineering to enhance their durability and performance. Each type of container chassis plays a vital role in the global market, catering to the diverse needs of the shipping and logistics industry. The choice of chassis depends on various factors, including the type of cargo, the transportation route, and the specific requirements of the shipping operation. As the demand for containerized transport grows, the market for these chassis types is expected to expand, driven by the need for efficient, reliable, and versatile transportation solutions.

Ports, Railway in the Container Chassis for Container Transport - Global Market:

Container chassis play a crucial role in the efficient operation of ports and railways, serving as the backbone of container transport in these areas. In ports, container chassis are indispensable for the movement of containers between ships and storage areas or onward transportation. They facilitate the quick and efficient transfer of containers from the dockside to trucks, enabling seamless integration into the broader supply chain. The use of container chassis in ports helps to minimize congestion and streamline operations, as they allow for the rapid loading and unloading of containers, reducing turnaround times for ships. This efficiency is vital in busy ports where time is of the essence, and any delays can have significant ripple effects throughout the supply chain. Container chassis are designed to withstand the harsh conditions of port environments, with robust construction and corrosion-resistant materials that ensure longevity and reliability. In railway operations, container chassis are equally important, providing a means to transport containers from rail terminals to their final destinations. Railways are a key component of intermodal transport, where containers are moved seamlessly between different modes of transport, such as ships, trains, and trucks. Container chassis enable this intermodal connectivity by allowing containers to be easily transferred from rail cars to road vehicles, facilitating efficient last-mile delivery. The use of container chassis in railway operations helps to optimize the flow of goods, as they provide a flexible and adaptable solution for transporting containers over long distances. This flexibility is particularly important in regions where rail infrastructure is well-developed, as it allows for the efficient movement of large volumes of cargo with minimal environmental impact. Container chassis used in railway operations are designed to meet specific requirements, such as compatibility with rail car dimensions and the ability to handle the dynamic forces encountered during rail transport. The integration of container chassis into port and railway operations is essential for the smooth functioning of global trade, as they provide the necessary link between different transport modes. As the demand for containerized transport continues to grow, the role of container chassis in these areas is expected to become even more critical, driving further innovation and development in the market.

Container Chassis for Container Transport - Global Market Outlook:

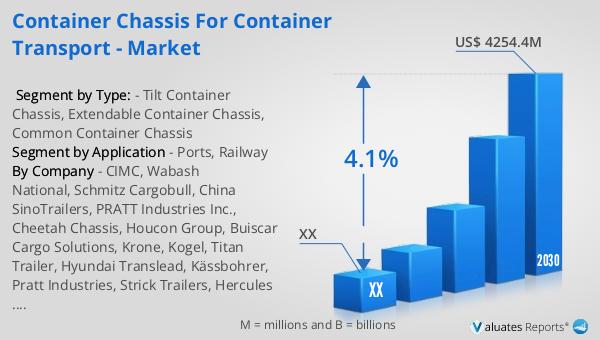

In 2023, the global market for container chassis used in container transport was valued at approximately $3,188 million. This market is projected to grow significantly, reaching an estimated size of $4,254.4 million by the year 2030. This growth represents a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This upward trend in the market is indicative of the increasing demand for efficient and reliable transportation solutions in the logistics industry. The growth can be attributed to several factors, including the expansion of global trade, the development of infrastructure, and the adoption of advanced technologies that enhance the performance and sustainability of container chassis. As industries continue to rely on containerized shipping for their logistical needs, the demand for robust and versatile container chassis is expected to rise. This market outlook highlights the importance of container chassis in the global supply chain, as they provide the necessary support for the efficient movement of goods across different modes of transport. The projected growth in the market underscores the critical role that container chassis play in facilitating international trade and ensuring the smooth operation of logistics networks. As the market continues to evolve, manufacturers and operators are likely to focus on innovation and sustainability to meet the growing demand for container chassis and to address the challenges of an increasingly complex and dynamic global trade environment.

| Report Metric | Details |

| Report Name | Container Chassis for Container Transport - Market |

| Forecasted market size in 2030 | US$ 4254.4 million |

| CAGR | 4.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | CIMC, Wabash National, Schmitz Cargobull, China SinoTrailers, PRATT Industries Inc., Cheetah Chassis, Houcon Group, Buiscar Cargo Solutions, Krone, Kogel, Titan Trailer, Hyundai Translead, Kässbohrer, Pratt Industries, Strick Trailers, Hercules Chassis, BWS Manufacturing Ltd., Montracon, Road Systems Inc., Talbert Manufacturing, Pitts Trailers, MAC Trailer Manufacturing, Stoughton Trailers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |