What is CNC Pipe Bending Machine - Global Market?

CNC Pipe Bending Machines are specialized equipment used in various industries to bend pipes and tubes into specific shapes and angles. These machines are crucial in manufacturing processes where precision and efficiency are paramount. The global market for CNC Pipe Bending Machines is expanding due to the increasing demand for automation and precision in industries such as automotive, aerospace, and construction. These machines use computer numerical control (CNC) technology to automate the bending process, ensuring high accuracy and repeatability. The market is driven by technological advancements, which have led to the development of more sophisticated machines capable of handling complex bending tasks. Additionally, the growing emphasis on reducing material waste and improving production efficiency is fueling the adoption of CNC Pipe Bending Machines. As industries continue to seek ways to enhance productivity and reduce costs, the demand for these machines is expected to rise, making them an integral part of modern manufacturing processes. The versatility and precision offered by CNC Pipe Bending Machines make them indispensable in producing high-quality components across various sectors.

Fully Electric CNC Pipe Bender, Hybrid CNC Pipe Bender, Hydraulic CNC Pipe Bender in the CNC Pipe Bending Machine - Global Market:

Fully Electric CNC Pipe Benders, Hybrid CNC Pipe Benders, and Hydraulic CNC Pipe Benders are three main types of CNC Pipe Bending Machines, each offering unique features and benefits. Fully Electric CNC Pipe Benders are known for their precision and energy efficiency. They use electric motors to control all axes of movement, providing high accuracy and repeatability. These machines are ideal for applications requiring complex bending tasks and are favored in industries where precision is critical, such as aerospace and automotive. The absence of hydraulic systems in these machines reduces maintenance requirements and eliminates the risk of hydraulic fluid leaks, making them environmentally friendly. Hybrid CNC Pipe Benders combine the best of both electric and hydraulic technologies. They use electric motors for certain movements and hydraulic systems for others, offering a balance between precision and power. This combination allows for greater flexibility in handling a wide range of bending tasks, making them suitable for various industrial applications. Hybrid machines are often used in industries where both precision and power are required, such as construction and heavy machinery manufacturing. Hydraulic CNC Pipe Benders, on the other hand, rely entirely on hydraulic systems to perform bending operations. These machines are known for their robustness and ability to handle large and heavy pipes. They are commonly used in industries where high force is needed, such as oil and gas, shipbuilding, and infrastructure development. While they may not offer the same level of precision as fully electric machines, their ability to handle heavy-duty tasks makes them indispensable in certain sectors. Each type of CNC Pipe Bending Machine has its advantages and is chosen based on the specific requirements of the application. The global market for these machines is diverse, with manufacturers continually innovating to meet the evolving needs of various industries. As technology advances, we can expect to see further improvements in the capabilities and efficiency of CNC Pipe Bending Machines, driving their adoption across different sectors.

Aerospace, Automotive, Home Appliances, General Industry, Others in the CNC Pipe Bending Machine - Global Market:

CNC Pipe Bending Machines play a crucial role in various industries, including aerospace, automotive, home appliances, general industry, and others. In the aerospace industry, these machines are used to manufacture complex components such as hydraulic tubes, fuel lines, and structural parts. The precision and repeatability offered by CNC Pipe Bending Machines are essential in ensuring the safety and performance of aerospace components. In the automotive industry, these machines are used to produce exhaust systems, chassis components, and other critical parts. The ability to bend pipes with high accuracy and consistency is vital in meeting the stringent quality standards of the automotive sector. CNC Pipe Bending Machines also contribute to reducing production time and costs, making them an attractive option for automotive manufacturers. In the home appliances sector, these machines are used to create components for products such as refrigerators, washing machines, and air conditioners. The demand for aesthetically pleasing and functional designs in home appliances drives the need for precise bending capabilities. CNC Pipe Bending Machines enable manufacturers to produce intricate designs with minimal material waste, enhancing the overall efficiency of the production process. In general industry, these machines are used in a wide range of applications, from construction and infrastructure development to the production of furniture and fixtures. The versatility of CNC Pipe Bending Machines allows them to handle various materials and sizes, making them suitable for diverse industrial applications. Other industries, such as shipbuilding, oil and gas, and renewable energy, also benefit from the capabilities of CNC Pipe Bending Machines. In shipbuilding, these machines are used to produce pipes and tubes for plumbing, ventilation, and structural components. In the oil and gas industry, they are used to manufacture pipelines and other critical infrastructure. The renewable energy sector uses CNC Pipe Bending Machines to produce components for wind turbines, solar panels, and other green technologies. The widespread use of CNC Pipe Bending Machines across different industries highlights their importance in modern manufacturing processes. As industries continue to evolve and demand more efficient and sustainable production methods, the role of CNC Pipe Bending Machines is expected to grow, driving further innovation and development in this field.

CNC Pipe Bending Machine - Global Market Outlook:

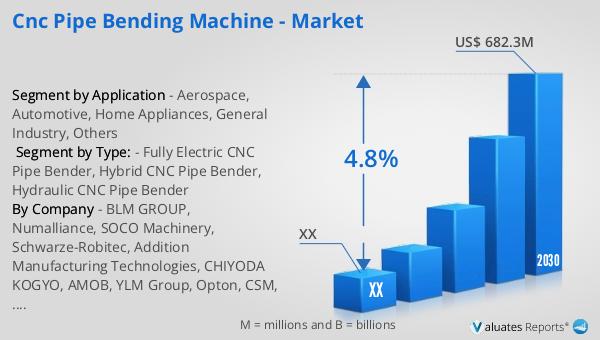

The global market for CNC Pipe Bending Machines was valued at approximately $496 million in 2023. This market is projected to grow significantly, reaching an estimated size of $682.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The increasing demand for precision and automation in manufacturing processes is a key driver of this market growth. Industries such as automotive, aerospace, and construction are increasingly adopting CNC Pipe Bending Machines to enhance production efficiency and reduce material waste. The technological advancements in CNC technology have led to the development of more sophisticated machines capable of handling complex bending tasks with high accuracy. This has further fueled the demand for CNC Pipe Bending Machines across various sectors. Additionally, the growing emphasis on sustainability and reducing environmental impact is driving the adoption of fully electric and hybrid CNC Pipe Bending Machines, which offer energy efficiency and reduced maintenance requirements. As industries continue to seek ways to improve productivity and reduce costs, the demand for CNC Pipe Bending Machines is expected to rise, contributing to the market's growth. The versatility and precision offered by these machines make them indispensable in producing high-quality components across different industries, further supporting their market expansion.

| Report Metric | Details |

| Report Name | CNC Pipe Bending Machine - Market |

| Forecasted market size in 2030 | US$ 682.3 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BLM GROUP, Numalliance, SOCO Machinery, Schwarze-Robitec, Addition Manufacturing Technologies, CHIYODA KOGYO, AMOB, YLM Group, Opton, CSM, COMCO, Unison Ltd, Transfluid Maschinenbau GmbH, Crippa, VLB Group, King-Mazon Machinery, SANCO GROUP, Herber Engineering AB, Dengler Tube, Taiyo Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |