What is Carbon Composite Hydrogen Tanks - Global Market?

Carbon composite hydrogen tanks are a crucial component in the storage and transportation of hydrogen fuel, which is increasingly being recognized as a clean and sustainable energy source. These tanks are made from carbon fiber composites, which provide a lightweight yet strong solution for storing hydrogen at high pressures. The global market for these tanks is expanding rapidly due to the growing demand for hydrogen as an alternative energy source. The use of carbon composites allows for the production of tanks that are not only lighter but also more durable and resistant to environmental factors compared to traditional materials. This makes them ideal for various applications, including automotive, aerospace, and industrial sectors. As the world shifts towards cleaner energy solutions, the demand for efficient and reliable hydrogen storage solutions like carbon composite tanks is expected to rise significantly. The market is driven by advancements in technology, increasing investments in hydrogen infrastructure, and supportive government policies promoting the use of hydrogen as a clean energy source.

Wet Winding, Dry Winding in the Carbon Composite Hydrogen Tanks - Global Market:

Wet winding and dry winding are two primary manufacturing techniques used in the production of carbon composite hydrogen tanks. Wet winding involves the impregnation of carbon fibers with resin before they are wound onto a mandrel to form the tank. This method allows for better control over the resin content and distribution, resulting in a more uniform and consistent composite structure. The wet winding process is typically used for producing high-pressure hydrogen tanks due to its ability to create a strong and durable composite material. On the other hand, dry winding involves winding pre-impregnated carbon fiber tapes or tows onto a mandrel. This method is often preferred for its cleaner production process and reduced curing time, as the resin is already present in the pre-impregnated fibers. Both wet and dry winding techniques have their advantages and are chosen based on the specific requirements of the hydrogen tank being produced. The choice between these methods depends on factors such as the desired mechanical properties, production volume, and cost considerations. As the demand for carbon composite hydrogen tanks continues to grow, manufacturers are investing in advanced winding technologies to improve efficiency and reduce production costs. The global market for these tanks is expected to benefit from ongoing research and development efforts aimed at enhancing the performance and reliability of hydrogen storage solutions.

Transportation, Gas Storage and Distribution, Others in the Carbon Composite Hydrogen Tanks - Global Market:

Carbon composite hydrogen tanks are used in various sectors, including transportation, gas storage and distribution, and other industrial applications. In the transportation sector, these tanks are essential for storing hydrogen fuel in vehicles such as cars, buses, and trucks. The lightweight nature of carbon composites makes them ideal for automotive applications, as they help reduce the overall weight of the vehicle, improving fuel efficiency and performance. Hydrogen-powered vehicles are gaining popularity as a clean alternative to traditional fossil fuel-powered vehicles, and the demand for efficient hydrogen storage solutions is increasing. In the gas storage and distribution sector, carbon composite hydrogen tanks are used to store and transport hydrogen gas safely and efficiently. These tanks are designed to withstand high pressures, ensuring the safe containment of hydrogen gas during transportation and storage. The use of carbon composites in these tanks provides a lightweight and durable solution, reducing transportation costs and improving safety. In addition to transportation and gas storage, carbon composite hydrogen tanks are also used in various industrial applications, such as power generation and chemical processing. The versatility and durability of these tanks make them suitable for a wide range of applications, contributing to the growing demand for carbon composite hydrogen tanks in the global market.

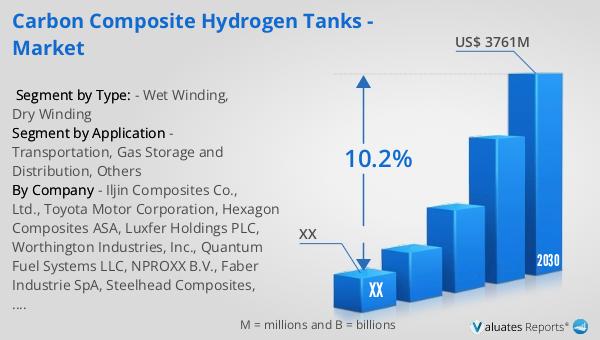

Carbon Composite Hydrogen Tanks - Global Market Outlook:

The global market for carbon composite hydrogen tanks was valued at approximately $1,905 million in 2023 and is projected to reach a size of around $3,761 million by 2030, growing at a compound annual growth rate (CAGR) of 10.2% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing adoption of hydrogen as a clean energy source and the need for efficient storage solutions. The North American market for carbon composite hydrogen tanks is also expected to experience substantial growth during this period. Although specific figures for the North American market were not provided, it is anticipated to follow a similar growth trajectory as the global market, driven by advancements in hydrogen infrastructure and supportive government policies. The increasing focus on reducing carbon emissions and transitioning to sustainable energy sources is expected to drive the demand for carbon composite hydrogen tanks in North America and other regions. As the market continues to expand, manufacturers are investing in research and development to improve the performance and cost-effectiveness of these tanks, further fueling market growth.

| Report Metric | Details |

| Report Name | Carbon Composite Hydrogen Tanks - Market |

| Forecasted market size in 2030 | US$ 3761 million |

| CAGR | 10.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Iljin Composites Co., Ltd., Toyota Motor Corporation, Hexagon Composites ASA, Luxfer Holdings PLC, Worthington Industries, Inc., Quantum Fuel Systems LLC, NPROXX B.V., Faber Industrie SpA, Steelhead Composites, INC., Faurecia (Ullit) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |