What is Automotive Parts Aluminium Diecasting - Global Market?

Automotive Parts Aluminium Diecasting is a significant segment within the global automotive industry, focusing on the production of lightweight and durable components. This process involves injecting molten aluminum into a mold to create parts that are essential for various automotive applications. The global market for these components is driven by the increasing demand for fuel-efficient vehicles, as aluminum parts contribute to reducing the overall weight of vehicles, thereby enhancing fuel efficiency. Additionally, the rise in electric vehicle production has further propelled the demand for aluminum diecast parts, as they are crucial in manufacturing lightweight battery enclosures and other components. The market is characterized by technological advancements, such as improved diecasting techniques and the development of high-strength aluminum alloys, which enhance the performance and durability of automotive parts. As the automotive industry continues to evolve, the demand for aluminum diecast parts is expected to grow, driven by the need for sustainable and efficient vehicle solutions.

Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, Semi-Solid Die Casting in the Automotive Parts Aluminium Diecasting - Global Market:

Pressure Die Casting is a widely used method in the automotive parts aluminum diecasting market, known for its ability to produce high-volume, complex parts with excellent surface finish and dimensional accuracy. This process involves forcing molten aluminum into a steel mold under high pressure, which allows for rapid production cycles and the creation of intricate shapes. The high-pressure environment ensures that the molten metal fills every cavity of the mold, resulting in parts with superior strength and minimal porosity. This method is particularly beneficial for producing engine components, transmission parts, and structural elements that require high precision and durability.

Body Assembly, Engine Parts, Transmission Parts, Others in the Automotive Parts Aluminium Diecasting - Global Market:

Vacuum Die Casting, on the other hand, is a variation of the traditional diecasting process that incorporates a vacuum to remove air and gases from the mold cavity before the molten aluminum is injected. This technique significantly reduces the risk of air entrapment, leading to parts with enhanced mechanical properties and reduced porosity. Vacuum diecasting is especially advantageous for producing parts that demand high integrity and strength, such as critical engine components and safety-related parts. The process also allows for thinner walls and more complex geometries, making it a preferred choice for manufacturers aiming to reduce weight without compromising on performance.

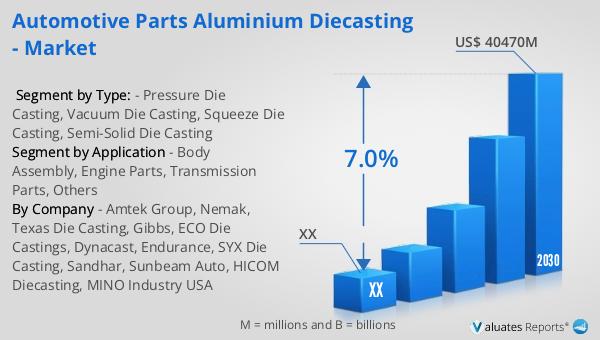

Automotive Parts Aluminium Diecasting - Global Market Outlook:

Squeeze Die Casting is another specialized technique used in the automotive parts aluminum diecasting market. This process involves applying pressure to the molten aluminum after it has been injected into the mold, effectively "squeezing" the metal to eliminate any gas pockets and improve the density of the final product. The result is a part with superior mechanical properties, including increased strength and ductility. Squeeze diecasting is ideal for producing components that require high structural integrity, such as suspension parts and chassis components. The process also allows for the use of higher-strength aluminum alloys, further enhancing the performance of the parts produced.

| Report Metric | Details |

| Report Name | Automotive Parts Aluminium Diecasting - Market |

| Forecasted market size in 2030 | US$ 40470 million |

| CAGR | 7.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Amtek Group, Nemak, Texas Die Casting, Gibbs, ECO Die Castings, Dynacast, Endurance, SYX Die Casting, Sandhar, Sunbeam Auto, HICOM Diecasting, MINO Industry USA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |