What is Automatic Overhead Conveyor System - Global Market?

Automatic overhead conveyor systems are an integral part of modern industrial operations, providing a streamlined method for transporting materials and products across various stages of production and logistics. These systems consist of a network of overhead tracks and trolleys that move items efficiently and safely, reducing the need for manual labor and minimizing the risk of damage during transit. The global market for these systems is driven by the increasing demand for automation in manufacturing and warehousing sectors, where efficiency and precision are paramount. As industries strive to enhance productivity and reduce operational costs, the adoption of automatic overhead conveyor systems is on the rise. These systems are particularly beneficial in environments where space is limited, as they utilize overhead space, freeing up valuable floor area for other operations. Additionally, they can be customized to fit specific industry needs, making them versatile solutions for a wide range of applications. The global market for automatic overhead conveyor systems is poised for growth as more industries recognize the benefits of automation and seek to integrate these systems into their operations.

Semi-Automatic, Fully-Automatic in the Automatic Overhead Conveyor System - Global Market:

In the realm of automatic overhead conveyor systems, the distinction between semi-automatic and fully-automatic systems is crucial for understanding their applications and benefits. Semi-automatic systems require some level of human intervention, typically in the form of manual loading and unloading of materials. These systems are often used in environments where complete automation is not feasible or cost-effective, or where human oversight is necessary for quality control. Semi-automatic systems offer a balance between automation and manual labor, providing efficiency while still allowing for human input. They are particularly useful in industries where customization and flexibility are required, as they can be easily adjusted to accommodate different products and processes. On the other hand, fully-automatic systems operate with minimal human intervention, relying on advanced technology and sensors to manage the entire process from start to finish. These systems are ideal for high-volume production environments where speed and precision are critical. Fully-automatic systems can significantly reduce labor costs and increase throughput, making them a popular choice for large-scale manufacturing operations. They are equipped with sophisticated control systems that monitor and adjust the conveyor's operation in real-time, ensuring optimal performance and minimizing downtime. The choice between semi-automatic and fully-automatic systems depends on various factors, including the nature of the products being handled, the level of automation desired, and the available budget. Both types of systems offer unique advantages and can be tailored to meet the specific needs of different industries. As technology continues to advance, the capabilities of both semi-automatic and fully-automatic systems are expected to expand, offering even greater efficiency and flexibility to users.

Production Process, Logistics, Others in the Automatic Overhead Conveyor System - Global Market:

Automatic overhead conveyor systems are utilized in various areas, including production processes, logistics, and other applications, each benefiting from the unique advantages these systems offer. In production processes, these systems streamline the movement of materials and products between different stages of manufacturing, reducing the time and labor required for manual handling. By automating the transportation of goods, manufacturers can increase their production capacity and improve overall efficiency. These systems are particularly beneficial in assembly lines, where they can be integrated with other automated equipment to create a seamless production flow. In logistics, automatic overhead conveyor systems play a crucial role in the efficient movement of goods within warehouses and distribution centers. They enable the rapid and accurate sorting and routing of products, reducing the time it takes to fulfill orders and improving customer satisfaction. By optimizing the use of space and minimizing the need for manual handling, these systems help logistics companies reduce operational costs and enhance their competitive edge. Beyond production and logistics, automatic overhead conveyor systems are also used in various other applications, such as in the automotive industry for moving car parts, in the food and beverage industry for transporting packaged goods, and in the pharmaceutical industry for handling delicate products. Their versatility and adaptability make them suitable for a wide range of industries, each benefiting from the increased efficiency and reliability these systems provide. As industries continue to evolve and demand more efficient and cost-effective solutions, the use of automatic overhead conveyor systems is expected to grow, further cementing their role as a vital component of modern industrial operations.

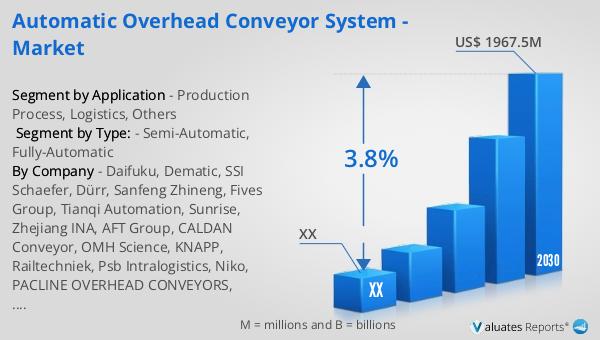

Automatic Overhead Conveyor System - Global Market Outlook:

The global market for automatic overhead conveyor systems was valued at approximately $1,522 million in 2023. Looking ahead, this market is projected to expand to a revised size of around $1,967.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% over the forecast period from 2024 to 2030. This growth trajectory underscores the increasing demand for automation solutions across various industries, driven by the need to enhance operational efficiency and reduce labor costs. As businesses continue to seek ways to optimize their production and logistics processes, the adoption of automatic overhead conveyor systems is expected to rise. These systems offer a range of benefits, including improved productivity, reduced manual handling, and enhanced safety, making them an attractive investment for companies looking to stay competitive in a rapidly evolving market. The projected growth in the global market for automatic overhead conveyor systems highlights the ongoing trend towards automation and the critical role these systems play in supporting industrial operations worldwide. As technology continues to advance, the capabilities of these systems are likely to expand, offering even greater efficiency and flexibility to users.

| Report Metric | Details |

| Report Name | Automatic Overhead Conveyor System - Market |

| Forecasted market size in 2030 | US$ 1967.5 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Daifuku, Dematic, SSI Schaefer, Dürr, Sanfeng Zhineng, Fives Group, Tianqi Automation, Sunrise, Zhejiang INA, AFT Group, CALDAN Conveyor, OMH Science, KNAPP, Railtechniek, Psb Intralogistics, Niko, PACLINE OVERHEAD CONVEYORS, Schönenberger Systeme, OCS (Axel Johnson), Richards-Wilcox Conveyor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |