What is Global X-ray Detector for Non-Destructive Testing Market?

The Global X-ray Detector for Non-Destructive Testing Market is a specialized segment within the broader field of non-destructive testing (NDT). NDT is a testing and analysis technique used in various industries to evaluate the properties of a material, component, or system without causing damage. X-ray detectors play a crucial role in this process by providing high-resolution images that help identify internal defects, structural integrity, and other critical parameters. These detectors are used in a wide range of applications, from aerospace and automotive to oil and gas, infrastructure, and energy sectors. The market for these detectors is driven by the increasing demand for high-quality, reliable testing methods that can ensure safety and compliance with stringent industry standards. Technological advancements, such as the development of digital X-ray detectors, have further fueled market growth by offering enhanced image quality, faster processing times, and greater ease of use. As industries continue to prioritize safety and efficiency, the demand for advanced X-ray detectors for non-destructive testing is expected to rise.

TFT, CMOS, Others in the Global X-ray Detector for Non-Destructive Testing Market:

Thin-Film Transistor (TFT), Complementary Metal-Oxide-Semiconductor (CMOS), and other technologies are pivotal in the Global X-ray Detector for Non-Destructive Testing Market. TFT technology is widely used in digital X-ray detectors due to its ability to provide high-resolution images and rapid data processing. TFT detectors consist of a matrix of thin-film transistors that convert X-ray photons into electrical signals, which are then processed to create detailed images. This technology is particularly beneficial in applications requiring high precision and accuracy, such as aerospace and defense, where even minor defects can have significant consequences. CMOS technology, on the other hand, offers several advantages, including lower power consumption, faster readout speeds, and higher sensitivity. CMOS detectors use a combination of photodiodes and transistors to convert X-ray photons into electrical signals, which are then amplified and processed to produce high-quality images. This technology is ideal for applications that require real-time imaging and rapid data acquisition, such as automotive and oil and gas industries. Other technologies, such as amorphous silicon and cadmium telluride detectors, also play a significant role in the market. Amorphous silicon detectors are known for their durability and cost-effectiveness, making them suitable for a wide range of industrial applications. Cadmium telluride detectors, on the other hand, offer high sensitivity and excellent energy resolution, making them ideal for specialized applications such as medical imaging and security screening. Each of these technologies has its unique advantages and is chosen based on the specific requirements of the application. The continuous advancements in these technologies are expected to drive the growth of the Global X-ray Detector for Non-Destructive Testing Market, as industries seek more efficient, accurate, and reliable testing solutions.

Aerospace & Defense, Automotive, Oil & Gas Industry, Infrastructure, Energy & Power, Others in the Global X-ray Detector for Non-Destructive Testing Market:

The usage of Global X-ray Detectors for Non-Destructive Testing spans across various industries, each with its unique requirements and challenges. In the aerospace and defense sector, X-ray detectors are used to inspect critical components such as turbine blades, airframes, and missile casings. These detectors help identify internal defects, cracks, and other anomalies that could compromise the safety and performance of aircraft and defense systems. In the automotive industry, X-ray detectors are employed to inspect engine components, welds, and other critical parts to ensure they meet stringent quality standards. This helps in preventing potential failures and enhancing the overall safety and reliability of vehicles. The oil and gas industry also relies heavily on X-ray detectors for non-destructive testing. These detectors are used to inspect pipelines, pressure vessels, and other critical infrastructure to detect corrosion, cracks, and other defects that could lead to catastrophic failures. In the infrastructure sector, X-ray detectors are used to inspect bridges, buildings, and other structures to ensure their structural integrity and safety. This is particularly important in regions prone to natural disasters such as earthquakes and hurricanes. The energy and power sector also benefits from the use of X-ray detectors for non-destructive testing. These detectors are used to inspect power plants, wind turbines, and other critical infrastructure to ensure they operate safely and efficiently. Other industries, such as manufacturing and electronics, also use X-ray detectors for quality control and inspection purposes. The versatility and reliability of X-ray detectors make them an indispensable tool in ensuring the safety, quality, and performance of various industrial applications.

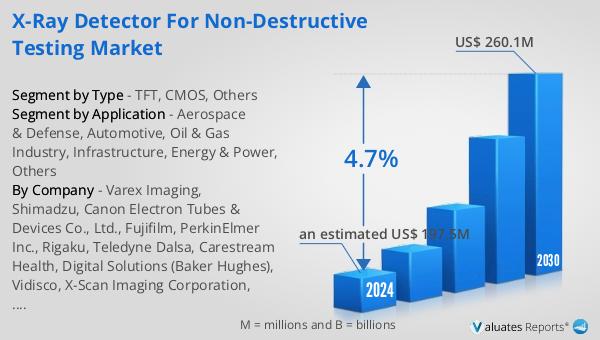

Global X-ray Detector for Non-Destructive Testing Market Outlook:

The global market for X-ray Detectors used in Non-Destructive Testing is anticipated to grow significantly, reaching an estimated value of US$ 260.1 million by 2030, up from US$ 197.5 million in 2024, with a compound annual growth rate (CAGR) of 4.7% between 2024 and 2030. The market is currently dominated by the top 12 companies, which collectively hold over 85% of the total market share. These leading companies are expected to maintain their strong position throughout the forecast period, driven by continuous innovation and the development of advanced X-ray detector technologies. The dominance of these companies is attributed to their extensive product portfolios, strong distribution networks, and significant investments in research and development. As industries increasingly prioritize safety, quality, and efficiency, the demand for high-performance X-ray detectors for non-destructive testing is expected to rise, further solidifying the market position of these leading companies.

| Report Metric | Details |

| Report Name | X-ray Detector for Non-Destructive Testing Market |

| Accounted market size in 2024 | an estimated US$ 197.5 million |

| Forecasted market size in 2030 | US$ 260.1 million |

| CAGR | 4.7% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Varex Imaging, Shimadzu, Canon Electron Tubes & Devices Co., Ltd., Fujifilm, PerkinElmer Inc., Rigaku, Teledyne Dalsa, Carestream Health, Digital Solutions (Baker Hughes), Vidisco, X-Scan Imaging Corporation, DÜRRNDT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |