What is Global Robot End Effectors Market?

The Global Robot End Effectors Market refers to the industry focused on the development, production, and distribution of end effectors for robots. End effectors are the devices at the end of a robotic arm, designed to interact with the environment. They can perform a variety of tasks such as gripping, welding, painting, and more. This market is driven by the increasing adoption of automation across various industries, including automotive, electronics, food and beverage, pharmaceuticals, and logistics. The demand for precision, efficiency, and safety in manufacturing processes has led to the widespread use of robotic end effectors. These devices are essential for enhancing the capabilities of robots, making them more versatile and efficient in performing complex tasks. The market is characterized by continuous innovation, with companies investing in research and development to create more advanced and specialized end effectors. This growth is also fueled by the need for customized solutions to meet specific industry requirements. As industries continue to embrace automation, the Global Robot End Effectors Market is expected to expand significantly, offering numerous opportunities for businesses and investors.

Robot Grippers, Robotic Tools in the Global Robot End Effectors Market:

Robot grippers and robotic tools are crucial components of the Global Robot End Effectors Market. Robot grippers are devices that enable robots to grasp and manipulate objects. They come in various types, including mechanical grippers, vacuum grippers, magnetic grippers, and adhesive grippers. Mechanical grippers use fingers or jaws to hold objects, making them suitable for handling a wide range of items. Vacuum grippers use suction to pick up objects, which is ideal for handling delicate or irregularly shaped items. Magnetic grippers use magnetic force to lift ferrous materials, while adhesive grippers use sticky surfaces to hold objects. Each type of gripper has its advantages and is chosen based on the specific requirements of the task. Robotic tools, on the other hand, are specialized devices attached to the end of a robotic arm to perform specific functions. These tools include welding torches, painting guns, screwdrivers, and cutting tools. They are designed to enhance the robot's capabilities, allowing it to perform tasks that require precision and consistency. For example, welding torches are used in automotive manufacturing to join metal parts, while painting guns are used to apply coatings evenly. Screwdrivers and cutting tools are used in assembly and disassembly processes in various industries. The choice of robotic tools depends on the application and the desired outcome. Both robot grippers and robotic tools are essential for the efficient functioning of robots in industrial settings. They enable robots to perform a wide range of tasks with high precision and speed, reducing the need for human intervention and increasing productivity. The development of advanced grippers and tools has also led to the creation of more versatile and adaptable robots. For instance, some modern grippers are equipped with sensors and artificial intelligence, allowing them to adjust their grip based on the object's shape and size. This adaptability is crucial in industries where the objects being handled vary in size and shape. Similarly, robotic tools with advanced features such as force control and real-time feedback enable robots to perform complex tasks with greater accuracy. The continuous innovation in robot grippers and robotic tools is driving the growth of the Global Robot End Effectors Market. Companies are investing in research and development to create more efficient and specialized end effectors that can meet the evolving needs of various industries. This has led to the introduction of new materials, designs, and technologies that enhance the performance and durability of grippers and tools. For example, the use of lightweight and durable materials such as carbon fiber and advanced polymers has improved the efficiency and lifespan of end effectors. Additionally, the integration of smart technologies such as sensors, artificial intelligence, and machine learning has enabled the development of intelligent end effectors that can adapt to different tasks and environments. These advancements are not only improving the performance of robots but also expanding their applications in new areas. As a result, the demand for robot grippers and robotic tools is expected to continue growing, driving the expansion of the Global Robot End Effectors Market.

Automotive, Semiconductor and Electronics, Food and Beverage, Pharmaceuticals, Industrial Machinery, Logistics in the Global Robot End Effectors Market:

The usage of Global Robot End Effectors Market spans across various industries, including automotive, semiconductor and electronics, food and beverage, pharmaceuticals, industrial machinery, and logistics. In the automotive industry, robotic end effectors are used for tasks such as welding, painting, assembly, and material handling. They enhance precision and efficiency, reducing production time and costs. For instance, welding torches and painting guns attached to robotic arms ensure consistent and high-quality finishes on car bodies. In the semiconductor and electronics industry, robotic end effectors are used for delicate tasks such as wafer handling, component placement, and assembly. Vacuum grippers and precision tools are essential for handling tiny and fragile components without causing damage. This ensures high accuracy and reliability in the production of electronic devices. In the food and beverage industry, robotic end effectors are used for packaging, sorting, and handling products. Vacuum grippers and specialized tools ensure hygienic and efficient handling of food items, reducing contamination risks and increasing productivity. For example, robots equipped with vacuum grippers can pick and place delicate food items such as pastries and fruits without causing damage. In the pharmaceutical industry, robotic end effectors are used for tasks such as drug dispensing, packaging, and lab automation. Precision tools and grippers ensure accurate and contamination-free handling of pharmaceutical products. This is crucial for maintaining the quality and safety of drugs. In the industrial machinery sector, robotic end effectors are used for tasks such as machining, assembly, and material handling. They enhance the efficiency and precision of manufacturing processes, reducing the need for manual labor and increasing productivity. For instance, robotic arms equipped with cutting tools can perform complex machining tasks with high accuracy. In the logistics industry, robotic end effectors are used for tasks such as picking, packing, and palletizing. They improve the efficiency of warehouse operations, reducing the time and effort required for manual handling. For example, robots equipped with grippers can pick and place items in a warehouse, streamlining the order fulfillment process. The versatility and efficiency of robotic end effectors make them indispensable in these industries. They not only enhance productivity but also improve the quality and consistency of products. The continuous innovation in end effector technology is further expanding their applications, driving the growth of the Global Robot End Effectors Market.

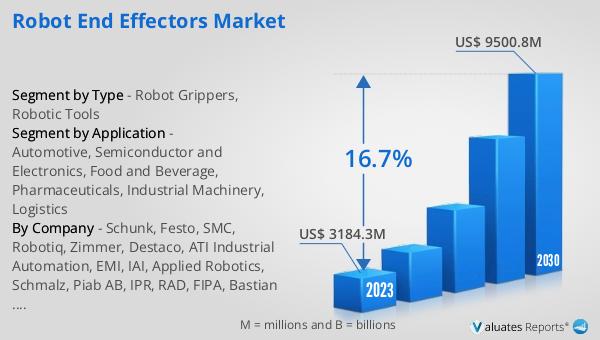

Global Robot End Effectors Market Outlook:

The global Robot End Effectors market is anticipated to grow significantly, with projections indicating it will reach approximately US$ 9500.8 million by 2030, up from an estimated US$ 3761.3 million in 2024. This growth represents a compound annual growth rate (CAGR) of 16.7% between 2024 and 2030. This substantial increase underscores the rising demand for automation and advanced robotic solutions across various industries. The market's expansion is driven by the need for precision, efficiency, and safety in manufacturing processes. As industries continue to adopt automation to enhance productivity and reduce operational costs, the demand for advanced robotic end effectors is expected to rise. Companies are investing in research and development to create more specialized and efficient end effectors that can meet the evolving needs of different industries. This growth also highlights the increasing importance of robotic end effectors in enhancing the capabilities of robots, making them more versatile and efficient in performing complex tasks. The continuous innovation and development in this market are expected to offer numerous opportunities for businesses and investors, driving further growth and expansion.

| Report Metric | Details |

| Report Name | Robot End Effectors Market |

| Accounted market size in 2024 | an estimated US$ 3761.3 million |

| Forecasted market size in 2030 | US$ 9500.8 million |

| CAGR | 16.7% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schunk, Festo, SMC, Robotiq, Zimmer, Destaco, ATI Industrial Automation, EMI, IAI, Applied Robotics, Schmalz, Piab AB, IPR, RAD, FIPA, Bastian Solutions, Soft Robotics, Grabit |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |