What is Global Plate Beveling Machines Market?

The Global Plate Beveling Machines Market refers to the worldwide industry focused on the production and sale of machines designed to create beveled edges on metal plates. These machines are essential in various industries where precise and clean edge preparation is crucial for welding and assembly processes. Plate beveling machines enhance the quality of welds by ensuring that the edges of metal plates are properly angled, which helps in achieving stronger and more reliable joints. The market encompasses a range of machines, from manual to fully automated systems, catering to different industrial needs and scales of operation. The demand for these machines is driven by the need for efficiency, precision, and safety in metalworking processes across various sectors such as construction, shipbuilding, automotive, and aerospace. As industries continue to advance and seek higher standards of production, the global plate beveling machines market is expected to grow, offering innovative solutions to meet the evolving requirements of metal fabrication.

Electric, Pneumatic, by Operation Mode, Manual, Automatic, by Placement, Base-mounted, Portable in the Global Plate Beveling Machines Market:

Electric and pneumatic plate beveling machines are two primary types based on their power sources. Electric beveling machines are widely used due to their efficiency and ease of use. They are powered by electricity and are suitable for continuous, heavy-duty operations. These machines are often preferred in industrial settings where a stable power supply is available. On the other hand, pneumatic beveling machines are powered by compressed air, making them ideal for environments where electrical sparks could pose a hazard, such as in oil and gas facilities. Pneumatic machines are also lighter and more portable compared to their electric counterparts, making them suitable for fieldwork and on-site applications. By operation mode, plate beveling machines can be categorized into manual and automatic types. Manual beveling machines require human intervention to operate, making them suitable for smaller-scale operations or tasks that require a high degree of precision and control. These machines are often used in workshops and small manufacturing units. Automatic beveling machines, however, are designed for high-volume production and can operate with minimal human intervention. They are equipped with advanced features such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems, which allow for precise and consistent beveling. These machines are commonly used in large-scale manufacturing facilities where efficiency and consistency are paramount. Based on placement, plate beveling machines can be classified into base-mounted and portable types. Base-mounted beveling machines are fixed in one location and are typically used in industrial settings where large volumes of metal plates need to be beveled. These machines are robust and can handle heavy-duty operations, making them suitable for continuous production lines. Portable beveling machines, on the other hand, are designed for mobility and flexibility. They are lightweight and can be easily transported to different job sites, making them ideal for fieldwork and on-site applications. Portable machines are often used in construction, shipbuilding, and repair work where the beveling needs to be done on-site. The versatility of these machines allows them to cater to a wide range of applications, from small-scale workshops to large industrial facilities.

Machine Manufacturing, Shipbuilding, Aerospace, Automotive, Oil & Gas, Power Utility, Others in the Global Plate Beveling Machines Market:

The usage of global plate beveling machines spans across various industries, each with its unique requirements and applications. In machine manufacturing, these machines are essential for preparing metal plates for welding and assembly. The beveled edges ensure that the welds are strong and reliable, which is crucial for the structural integrity of the machines being produced. In the shipbuilding industry, plate beveling machines are used to prepare the edges of large metal plates that form the hulls and other structural components of ships. The precise beveling ensures that the welds are watertight and can withstand the harsh marine environment. In the aerospace industry, the need for precision and reliability is even more critical. Plate beveling machines are used to prepare metal plates for the construction of aircraft components, where even the smallest imperfection can have significant consequences. The automotive industry also relies on plate beveling machines for the production of various components, including chassis and body panels. The beveled edges ensure that the welds are strong and can withstand the stresses and strains of everyday use. In the oil and gas industry, plate beveling machines are used to prepare metal plates for the construction of pipelines and other infrastructure. The precise beveling ensures that the welds are strong and can withstand the high pressures and corrosive environments typical of this industry. The power utility sector also benefits from the use of plate beveling machines, particularly in the construction and maintenance of power plants and other infrastructure. The beveled edges ensure that the welds are strong and reliable, which is crucial for the safe and efficient operation of power facilities. Other industries that use plate beveling machines include construction, where they are used to prepare metal plates for structural components, and repair and maintenance, where they are used to prepare metal plates for welding and other repair work. The versatility and precision of plate beveling machines make them an essential tool in a wide range of industries, ensuring that metal plates are prepared to the highest standards for welding and assembly.

Global Plate Beveling Machines Market Outlook:

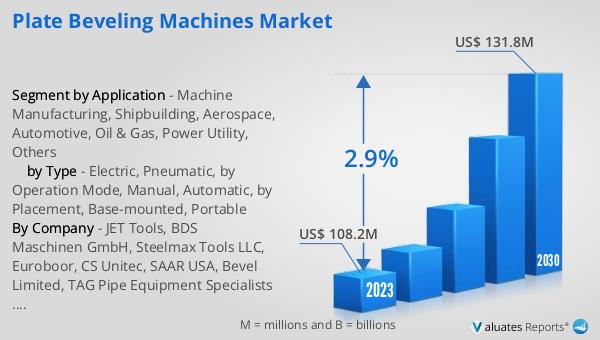

The global Plate Beveling Machines market was valued at US$ 108.2 million in 2023 and is anticipated to reach US$ 131.8 million by 2030, witnessing a CAGR of 2.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing demand for precision and efficiency in metalworking processes across various sectors. The growth is attributed to the rising adoption of advanced manufacturing technologies and the need for high-quality welds in industries such as construction, shipbuilding, automotive, and aerospace. The market's expansion is also supported by the continuous development of innovative beveling machines that offer enhanced performance, ease of use, and safety features. As industries strive to improve their production capabilities and meet stringent quality standards, the demand for plate beveling machines is expected to grow. This growth is further fueled by the increasing investments in infrastructure development and the modernization of manufacturing facilities worldwide. The market's positive outlook reflects the critical role that plate beveling machines play in ensuring the structural integrity and reliability of welded joints, which are essential for the safety and performance of various industrial applications.

| Report Metric | Details |

| Report Name | Plate Beveling Machines Market |

| Accounted market size in 2023 | US$ 108.2 million |

| Forecasted market size in 2030 | US$ 131.8 million |

| CAGR | 2.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JET Tools, BDS Maschinen GmbH, Steelmax Tools LLC, Euroboor, CS Unitec, SAAR USA, Bevel Limited, TAG Pipe Equipment Specialists Ltd, Gullco Internationals, Baileigh Industrial, Shanghai Huawei Welding & Cutting Machine Co., Ltd, SHANGHAI TAOLE MACHINERY CO. LTD, Pokou Machinery (Shanghai) Co., Lt |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |